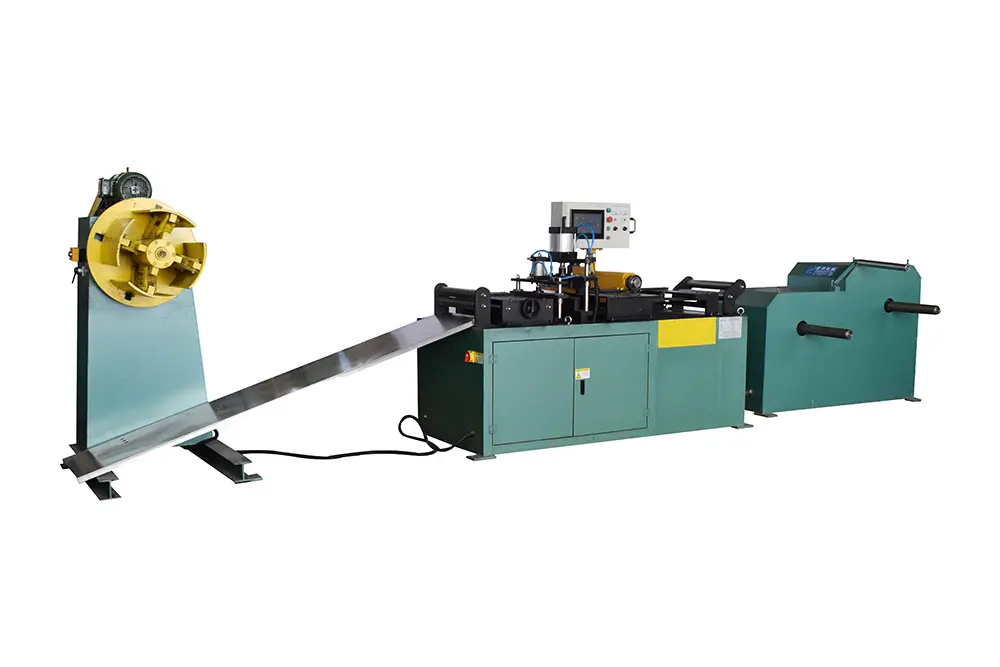

3D Wound Core Curve Cutting Machine for Transformer Core Manufacturing

Product Specification

| Code | SHKL-400 |

| Cutting type | straight/curve |

| Max feeding width | 400MM |

| Cutting speed | 0-60M/min |

| Cutting method | Cut one into two strip |

| Material utilization | 99% |

| Cutting accuracy | ±0.3MM |

| Cutting burr | ≤0.03MM |

| Speed adjusting way | Stepless speed adjust |

Advantages

1. Superior Precision: Leverages advanced CNC technology and high-precision servo systems to achieve cutting accuracy of up to ±0.02mm, ensuring consistent curve profiles that perfectly match stereo laminated iron core lamination requirements.

2. High Efficiency: Integrates automatic material feeding, curve programming and waste collection. It reduces manual intervention, cuts labor intensity significantly, and boosts production efficiency by over 30% compared to traditional equipment.

3. Strong Adaptability: Equipped with intelligent sensors for real-time silicon steel sheet thickness monitoring and automatic parameter adjustment, enabling smooth handling of different grades of silicon steel and complex curve cutting tasks.

4. Stable & Durable Operation: Features a rigid frame structure that minimizes vibration during high-speed cutting, maintaining long-term cutting stability. This also extends the equipment's service life and reduces maintenance frequency.

5. User-Friendly & Safe: Comes with an intuitive HMI for easy operation and real-time process monitoring. Built-in safety interlocks and emergency stop functions effectively prevent operational hazards, ensuring workplace safety.

6. Seamless Workflow Integration: Compatible with CAD/CAM systems, allowing direct import of design files. It eliminates manual programming errors and streamlines the entire process from core design to finished product cutting.

7. Waste Reduction: Precise cutting control minimizes material waste, lowering raw material costs for transformer core manufacturing while improving the overall quality of finished cores.

Details Display

Application

1. Power Transformer Manufacturing:

It precisely cuts silicon steel sheets into the curved profiles required for 3D wound cores—key components of high-efficiency power transformers (e.g., distribution transformers, power plant main transformers). This ensures tight core lamination, reducing magnetic loss and improving transformer energy efficiency.

2. Special Transformer Production:

Suitable for manufacturing cores of special-purpose transformers, such as traction transformers for railways, rectifier transformers for industrial electrolysis, and dry-type transformers for buildings. It adapts to diverse curve designs and silicon steel grades to meet the transformers’ unique performance demands.

3. High-Frequency Transformer & Inductor Making:

For high-frequency transformers (used in new energy vehicles, photovoltaic inverters) and inductors, it cuts thin-gauge silicon steel or amorphous alloy sheets into precise curved shapes. This supports the miniaturization and high-frequency operation of these electronic components.

4. Renewable Energy Equipment:

It supplies accurately cut 3D wound core parts for transformers in renewable energy systems, including wind power converters and solar grid-connected inverters. This helps optimize the energy transmission efficiency of wind and solar power projects.