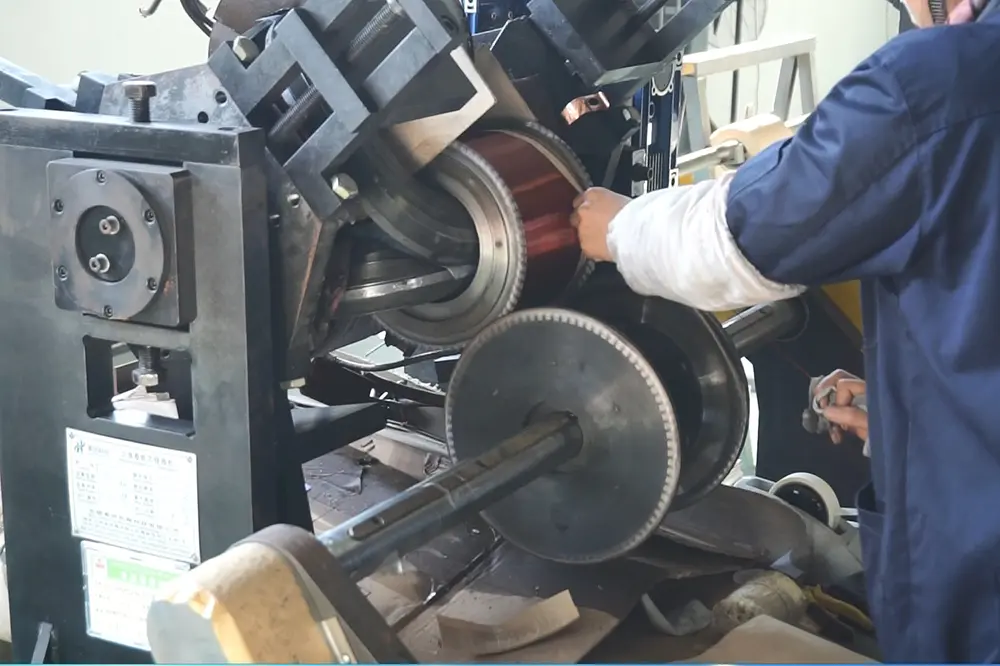

3D Wound Core Winding Machine for Transformer Manufacturing

Product Specification

| Code | SHRX-1 |

| Suitable transformer capacity | 30~1250kVA |

| Winding method | Horizontal type |

| Up and down distance | 200MM |

| Front and back max distance | 250MM |

| Drive gear revolving speed | 0-300r/min |

| Control system | PLC, Touch screen |

| Code | SHRX-2 |

| Suitable transformer capacity | 30-630KVA |

| Winding method | Horizontal type |

| Front and back max distance | 500MM |

| Drive gear revolving speed | 0-300r/min |

| Control system | , Touch screen |

Advantages

1. Ultra-High Winding Precision

Boasts ±0.01mm winding accuracy, ensuring uniform coil arrangement. It effectively reduces core loss of transformers/inductors and improves the qualification rate of finished products.

2. High Production Efficiency

30% more efficient than traditional winding machines. Equipped with automatic feeding and tension control, it minimizes manual intervention and shortens production cycles.

3. Strong Specification Adaptability

Flexibly accommodates 3D wound cores of different sizes (range customizable). No need for frequent mold replacement, suitable for multi-variety and small-batch production needs.

4. Stable & Durable Operation

Constructed with high-strength steel, it resists vibration and wear during long-term use. The intelligent fault alarm function reduces downtime and lowers maintenance costs.

5. User-Friendly Operation

Comes with a touch-screen control interface and pre-set process parameters. New operators can master it quickly, reducing training costs for enterprises.

Product Display

Application

1. Distribution Transformers (Primary Application)

Widely used in the production of medium and low-voltage distribution transformers. It precisely winds copper/aluminum wires on 3D wound cores, matching the core’s special annular structure to reduce magnetic flux loss. This directly improves the transformer’s energy efficiency (meeting IE2/IE3 standards) and operational stability.

2. Industrial Inductors

Applied to manufacturing various industrial inductors, including filter inductors, rectifier inductors, and reactor inductors. The machine’s adjustable tension control ensures tight and uniform wire winding, which is critical for inductors to maintain stable inductance values in power supply, frequency conversion, and other industrial systems.

3. New Energy Power Equipment

Adapted to the production of power components in new energy fields, such as photovoltaic (PV) inverters, energy storage transformers, and electric vehicle (EV) on-board transformers. It handles small-size, high-precision 3D wound cores, satisfying the equipment’s requirements for miniaturization and high reliability.

4. Special Power Equipment

Used in manufacturing special power equipment for scenarios like high-speed railways, ships, and aerospace. It can customize winding processes for non-standard 3D wound cores, meeting the strict environmental adaptability requirements (e.g., vibration resistance, high temperature resistance) of such equipment.