Automatic Single-layer Foil Winding Machine

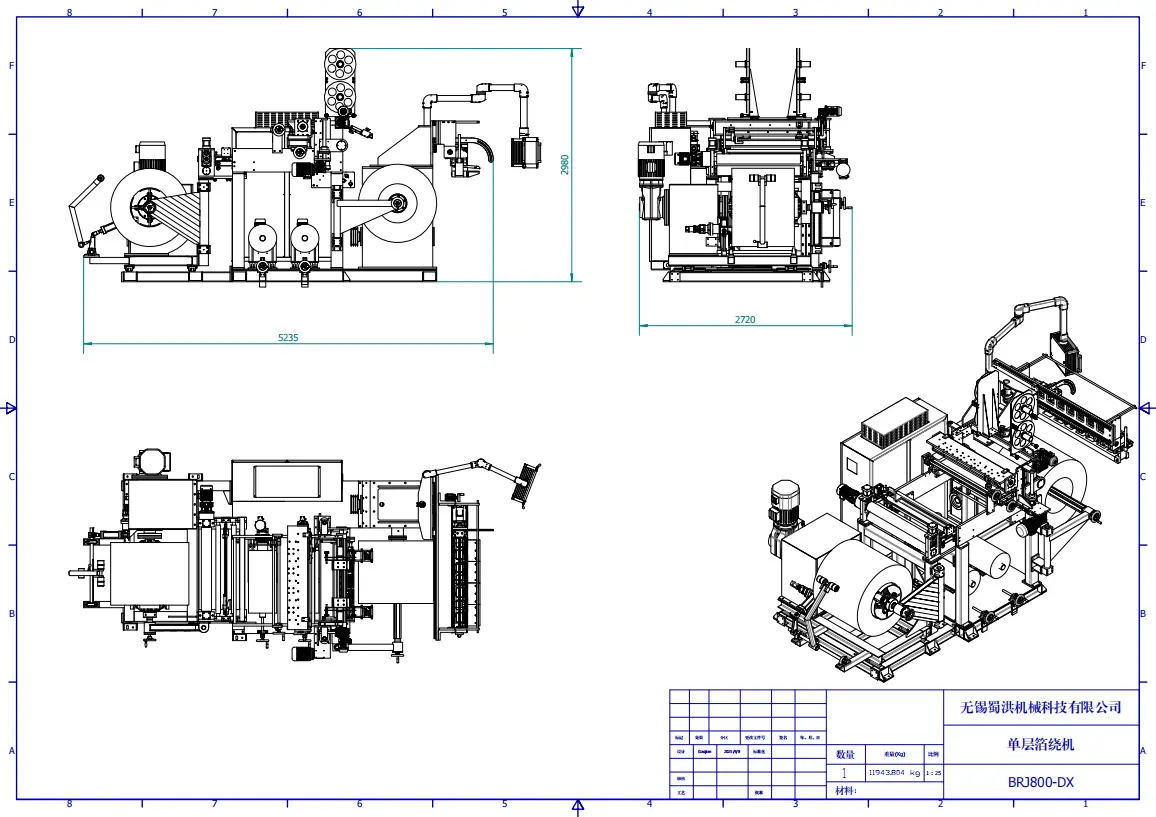

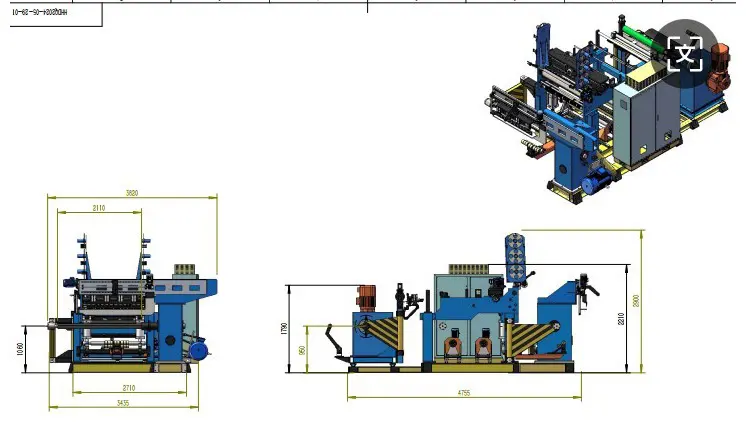

Product Drawing

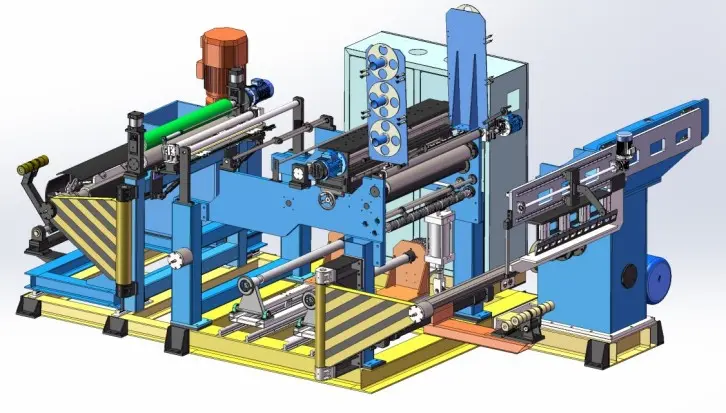

3D Picture

Product Specification

Code |

SH-600 |

SH-800 |

SH-1100 |

SH-1400 |

Coil outer diameter |

150-750mm |

150-850mm |

200-1000mm |

200-1000mm |

Foil width |

100-600mm |

150-800mm |

200-1100mm |

300-1400mm |

Foil layers |

Single or double |

|||

Foil thickness |

铜Cu:0.3-2.5mm 铝Al: 0.5-3.0mm |

|||

Winding speed |

0-30r/min |

0-30r/min |

0-20r/min |

0-20r/min |

Max tension of foil |

6000N |

8000N |

10000N |

14000N |

Welding speed |

0-0.5 m/min |

|||

Correction precision |

±0.5mm |

|||

Welding method |

TIG or cold pressure welding |

|||

Advantages

1. Precise Winding Performance: Precise tension control and uniform layer distribution. ensuring consistent coil dimensional accuracy.

2. High Production Efficiency: Automatic foil feeding & winding. reducing manual intervention and shortening production cycle.

3. Wide Material Adaptability: Compatible with various metal foils (copper. aluminum. etc.) of different thicknesses.

4. Stable & Reliable Operation: Rigid structure design and advanced control system. ensuring long-term stable running.

5. Easy Operation & Maintenance: User-friendly interface and simplified structure. lowering operation threshold and maintenance cost.

6. Superior Coil Quality Guarantee: Minimizes manual errors. meeting high-standard requirements of power equipment manufacturing.

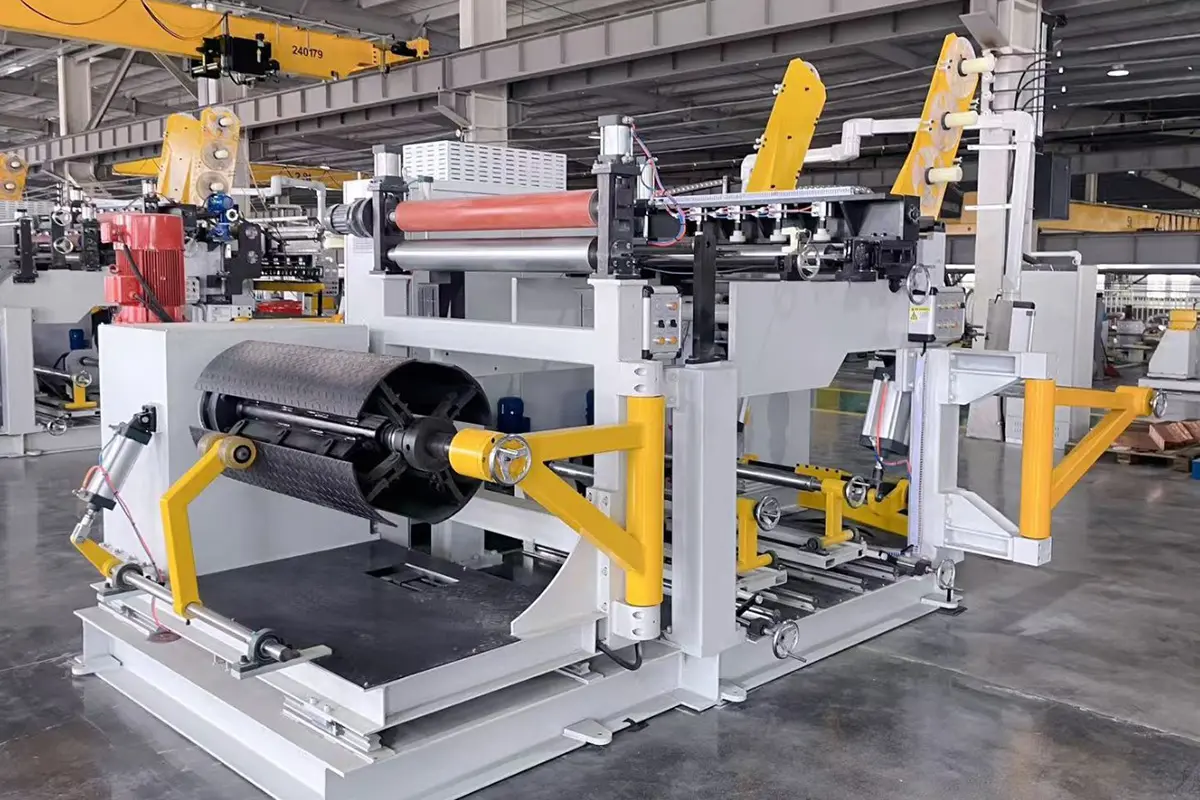

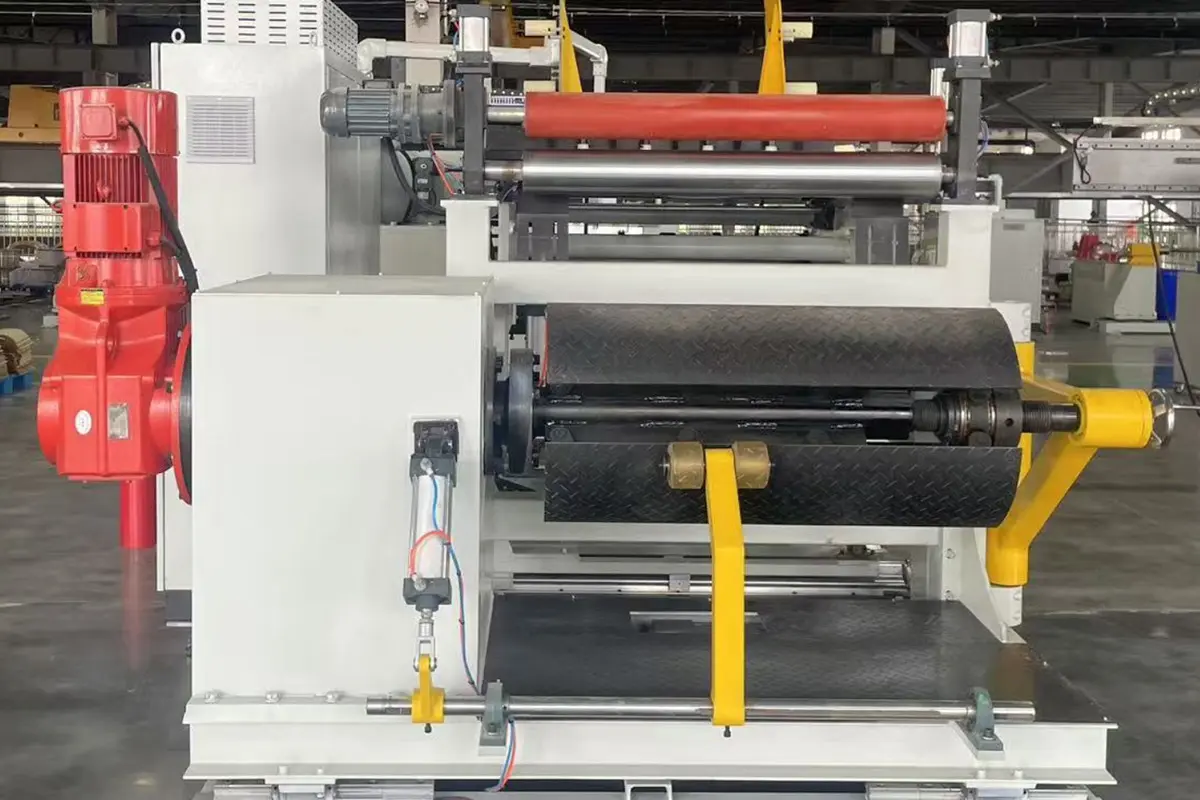

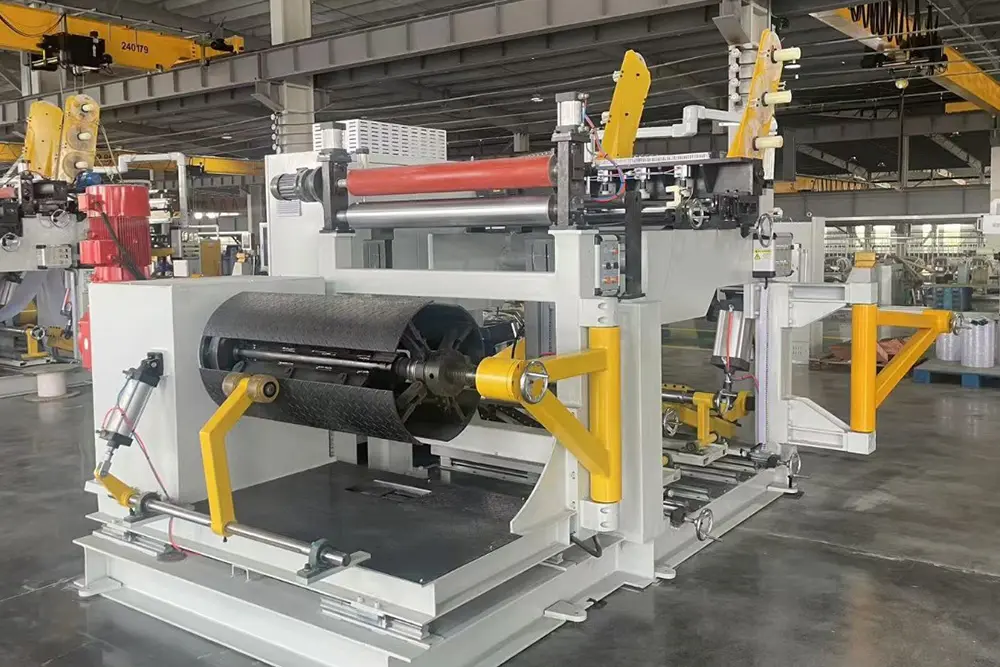

Product Display

Application

1. Power Transformer Sector: Core equipment for winding single-layer foil coils in medium/low-voltage power transformers.

2. Inductor & Reactor Manufacturing: Applied to produce foil coils for inductors. reactors and other magnetic components.

3. New Energy Field: Suitable for coil winding in new energy converters. energy storage systems and PV inverters.

4. Industrial Power Supply Field: Used for coil production of industrial power supplies. UPS and voltage stabilizers.

5. Rail Transit Electrical Equipment: Applied to winding coils for rail transit traction transformers and auxiliary electrical devices.