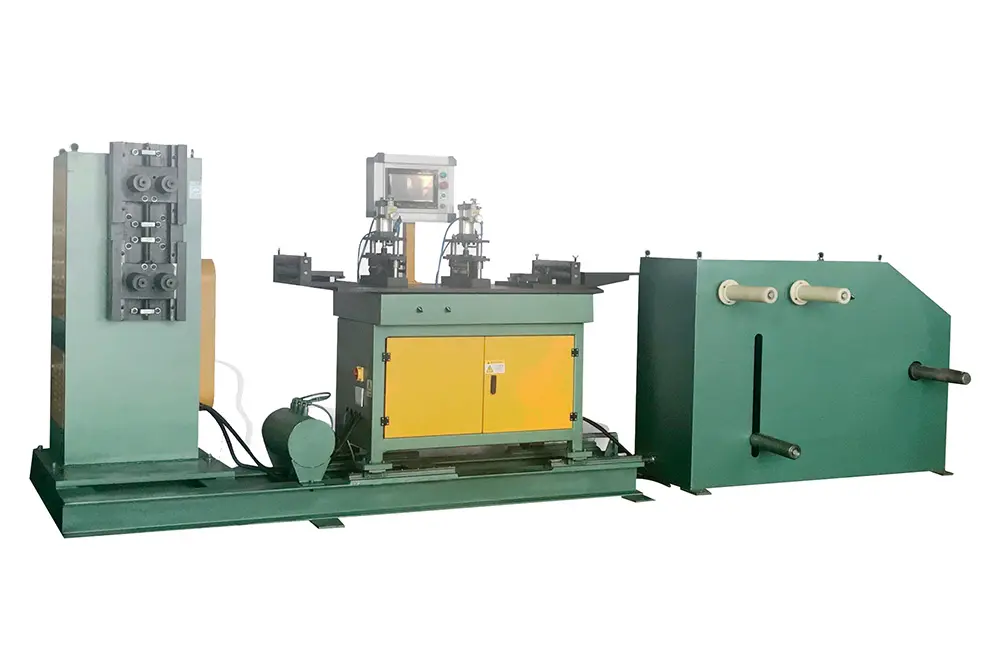

Automatic Winding Machine for R-Type Planar Wound Cores (Transformer-Specific)

Product Specification

| Code | SHPMJR- | |

| Maximum core outer diameter | 300MM | |

| maximum gyration diameter | Add clamping roller | R600MM |

| No clamping roller | R800MM | |

| Core winding speed | 0-45r/min | |

| Total Power | 9.5KW | |

| Speed adjusting way | Frequency conversion stepless speed adjust | |

| Control system | PLC Touch screen | |

Advantages

1. Full-Automatic & Labor-Saving Operation:Integrates automatic silicon steel sheet feeding, precise tension control, and real-time winding monitoring. It completely replaces manual winding (which is labor-intensive and error-prone), reducing labor costs by 40%+ and eliminating human-induced defects (e.g., uneven lamination), ensuring consistent quality across batches of R-type planar wound cores.

2. Ultra-High Winding Precision:Achieves ±0.1mm winding accuracy, effectively guaranteeing core concentricity and tight lamination of silicon steel sheets. This avoids air gaps between laminations— a key factor that causes magnetic loss in transformers— directly improving the energy efficiency and stable performance of final R-type core transformers.

3. Strong Spec Compatibility:Flexibly adapts to R-type planar wound cores of different sizes (e.g., for small distribution transformers or industrial control transformers) and silicon steel types (GO/NGO). No frequent mold replacement or complex parameter debugging is needed, shortening setup time by 50% and enhancing the flexibility of production lines.

4. Efficient & Low-Waste Production:Boasts high-speed winding capabilities (20% faster than semi-automatic equipment) to boost production capacity. The precise tension control prevents silicon steel sheet tearing or deformation during winding, reducing material waste to less than 1%. Its stable mechanical structure also minimizes equipment downtime, ensuring continuous and efficient manufacturing.

Product Display

Application

1. Distribution Transformer Manufacturing

It is widely used to wind R-type planar wound cores (made of GO silicon steel sheets) for low-loss distribution transformers (common in power grids and residential/commercial power supply). The machine’s ±0.1mm winding precision ensures tight lamination and high concentricity of the core, reducing magnetic loss and no-load noise of the transformer. This helps the final product meet energy-saving standards (e.g., IEC Class 1) and adapt to the demand for efficient power transmission in modern grids.

2. Electronic & Control Transformer Production

For small-sized electronic transformers (used in household appliances like air conditioners, refrigerators) and industrial control transformers (for PLC systems, frequency converters), the machine adapts to miniaturized R-type core specs. It realizes automated winding of thin GO/NGO silicon steel sheets, ensuring the core’s compact structure and stable magnetic performance—critical for the miniaturization of electronic devices and the precision of industrial control signals.

3. Special Transformer Manufacturing (New Energy & Rail Transit)

In the production of photovoltaic inverter transformers and EV charging pile transformers (new energy sector), as well as rail transit auxiliary transformers, the machine provides high-consistency R-type core winding. Its ability to handle diverse silicon steel materials and adjust winding parameters meets the special requirements of these fields—such as resistance to high temperature, low magnetic loss, and long-term stability—laying a foundation for the reliable operation of new energy and rail transit equipment