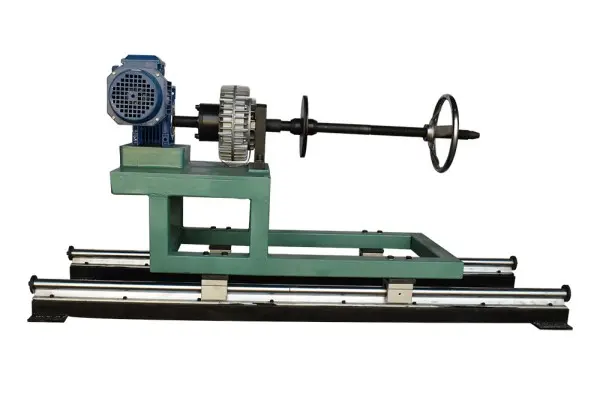

Buy Wholesale CNC Coil Winding Machines | Direct from the Factory

WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD. provides high-quality and efficient Cnc Coil Winding Machines designed to enhance production processes. Our machines ensure precision and durability, essential for producing superior coils. We remain responsive to market demands, incorporating a variety of features to suit your specific requirements. Additionally, we offer competitive discounts on bulk purchases, making it easier to achieve excellent value. As a dedicated manufacturer, we focus on customer satisfaction and maintain rigorous quality control at every stage of production. Our Cnc Coil Winding Machines are the perfect solution for expanding capabilities and streamlining operations in your business.

Tips & Tricks for Cnc Coil Winding Machine Supplies the World’s Top Brands For the Current Year

In the ever-evolving landscape of manufacturing, CNC coil winding machines have become indispensable tools for creating high-quality coils essential for various industries, from electronics to renewable energy. As global demand for efficient production practices grows, suppliers must stay ahead of the curve by investing in advanced technology and understanding the unique requirements of different markets. One key tip for procurement is to evaluate the technology used in CNC machines. Opt for suppliers that prioritize innovation, offering machines equipped with cutting-edge features that enhance precision and efficiency.

Another crucial aspect is understanding the importance of quality service and support. When sourcing CNC coil winding machines, consider suppliers who provide comprehensive after-sales support, including training, maintenance, and troubleshooting assistance. This ensures that your investment continues to yield optimal results and minimizes downtime. Moreover, staying informed about market trends and customer feedback can guide buyers in selecting the best machines that cater to current demands.

Finally, sustainability should be at the forefront of procurement strategies. Look for manufacturers that focus on environmentally friendly practices, not only in their machinery but also in the materials used for production. By aligning with suppliers committed to sustainable practices, businesses can contribute to a greener future while meeting the rising global demand for eco-conscious products. Implementing these tips and tricks can lead to more informed purchasing decisions that ultimately enhance operational efficiency and output quality in today's competitive landscape.

Tips & Tricks for Cnc Coil Winding Machine Supplies the World’s Top Brands For the Current Year

| Feature | Description | Benefit |

|---|---|---|

| High Precision | Utilizes advanced sensors to ensure accuracy in winding | Reduces material waste and improves product quality |

| User-Friendly Interface | Intuitive controls and touchscreen functionality | Speeds up training and operation time |

| Energy Efficiency | Low power consumption designs with smart energy management | Reduces operational costs and environmental impact |

| Versatile Winding Options | Capable of handling various wire types and sizes | Enhances flexibility for different production needs |

| Automated Features | Integration of automatic tension control and spool management | Increases productivity by minimizing manual tasks |

| Real-Time Monitoring | Allows tracking of machine performance and diagnostics | Facilitates preventive maintenance and uptime maximization |

Why Professionals Prefer Cnc Coil Winding Machine Service Your End-to-End Solution

B

Benjamin Turner

The quality is impressive, and the after-sales staff demonstrated remarkable professionalism in addressing my questions.

19

August

2025

I

Isaac Hall

I am very pleased with this purchase! The excellent quality combined with the helpful customer service made it worthwhile.

31

July

2025

J

James Mitchell

Highly satisfied with my purchase. The product quality is exceptional, and the follow-up support was incredibly professional.

26

August

2025

E

Evelyn Collins

Excellent purchase! The product quality is outstanding, and the after-sales team handled my inquiries with great professionalism.

22

August

2025

D

Daniel Garcia

The craftsmanship of this item is truly excellent. I appreciate the level of professionalism shown by the after-sales team; they were incredibly helpful.

13

September

2025

O

Olivia Rodriguez

Very pleased with this product! The build quality is superb, and the support staff was attentive and knowledgeable, making my experience seamless.

09

September

2025