Coil The Wire: Leading Manufacturer & Supplier of Quality Wire Products in China

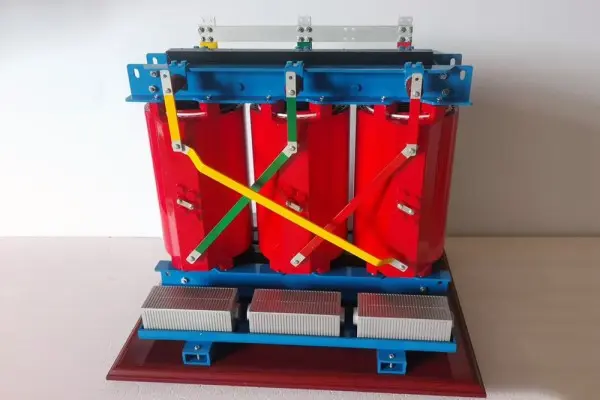

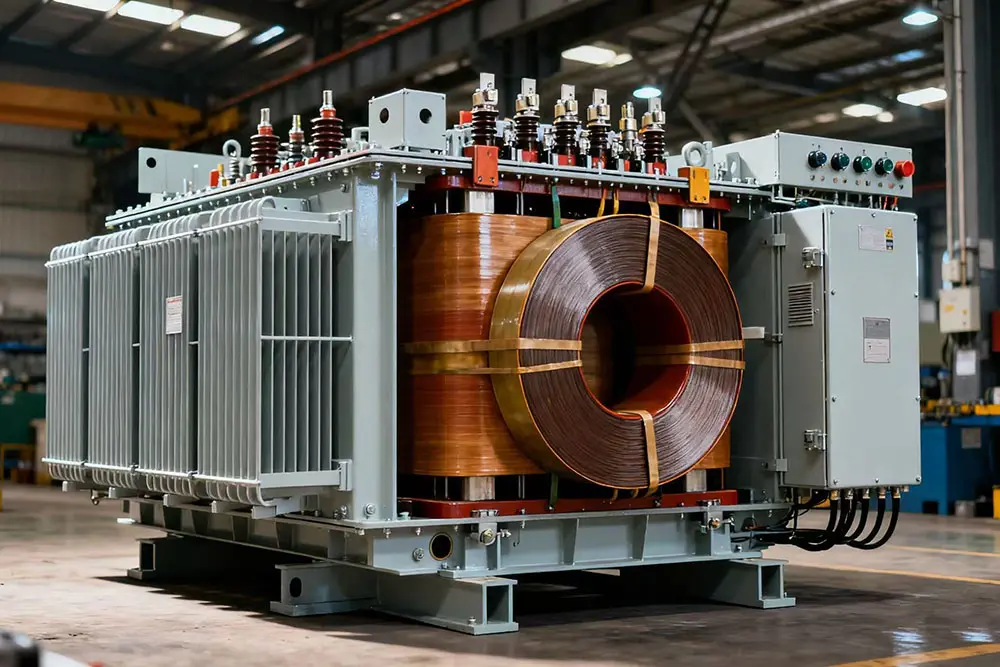

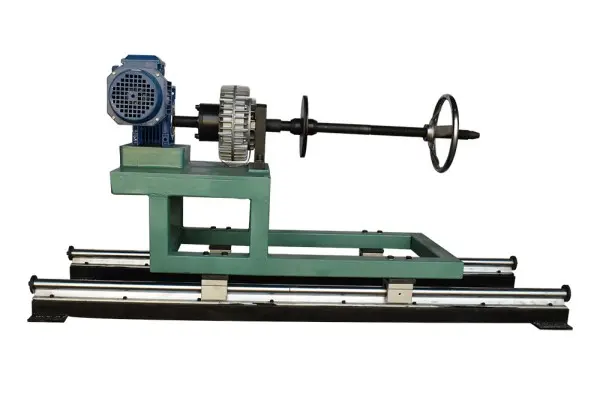

Wuxi Shuhong Machinery Technology Co., Ltd. specializes in providing high-quality custom coil wire solutions designed to meet your precise requirements. Our commitment to excellence ensures that each product is manufactured with advanced technology, delivering exceptional precision and durability to meet rigorous industry standards.

Methods To choose Coil The Wire Is The Best Sets the Industry Standard

Choosing the right coil wire is essential for any industry aiming for efficiency and durability. With the continuous evolution of technology, it becomes imperative to stay informed about the best methods to select coil wire that sets the industry standard. First and foremost, consider the specific material requirements. Different applications demand various wire materials, such as copper, aluminum, or specialized alloys. Understanding the conductivity, strength, and resistance properties of these materials will guide you toward the most suitable option for your project.

Furthermore, pay attention to the manufacturing standards and certifications associated with the coil wire. Selecting wire produced under stringent quality controls ensures you receive a product that not only meets but exceeds industry benchmarks. It's also beneficial to evaluate the technical specifications, such as gauge size, insulation type, and temperature ratings, to determine how well the wire can perform under specific conditions. By prioritizing these aspects, you can make informed decisions that lead to enhanced performance and reliability in your applications.

Finally, engage with suppliers who demonstrate a commitment to innovation and customer service. A strong partnership with knowledgeable vendors can provide valuable insights into emerging technologies and methods in wire production. By leveraging their expertise, you can ensure you are equipped with the best coil wire solutions to empower your projects and drive your success in the competitive industrial landscape.

Methods To choose Coil The Wire Is The Best Sets the Industry Standard

| Method | Description | Advantages | Industries Applicable |

|---|---|---|---|

| Magnetic Field Measurement | Utilizes sensors to evaluate coil performance via magnetic field analysis. | Accurate performance tracking and early fault detection. | Electricity, Manufacturing |

| Mechanical Testing | Tests structural integrity through tensile and compression tests. | Ensures durability and reliability under stress. | Automotive, Aerospace |

| Thermal Imaging | Uses infrared cameras to detect heat patterns in coils. | Identifies overheating issues that may lead to failures. | HVAC, Electrical Systems |

| Electrical Resistance Testing | Measures the resistance of wire materials to ensure efficient operation. | Detects corrosion and material degradation. | Power Generation, Telecommunications |

| Coil Winding Inspection | Visual and systematic inspection of wire winding for uniformity. | Improves quality control and reduces production defects. | Industrial Manufacturing, Robotics |

How To Identify Coil The Wire Industry Leaders Where Innovation Meets 2025

E

Emma Wilson

High-quality product, no doubt! The support team is truly dedicated and knowledgeable, making my experience smooth and enjoyable.

10

September

2025

E

Ethan Clark

This product is of exceptional quality. The customer service staff were very professional and resolved my concerns efficiently.

24

August

2025

A

Avery Martin

Unbelievable quality! The expertise and professionalism of their support team were evident when addressing my inquiries.

03

August

2025

A

Alexander White

The quality of the item is exceptional. I also found the after-sales service to be very helpful and reassuring.

25

August

2025

D

Daniel Young

The quality of this item is top-tier. The customer service team demonstrated great professionalism in addressing my queries.

18

August

2025

E

Evelyn Collins

Excellent purchase! The product quality is outstanding, and the after-sales team handled my inquiries with great professionalism.

22

August

2025