Top Automatic Coil Winding Machine Manufacturer | Quality Factory Solutions

Our Coil Winding Machine Automatic is expertly designed to streamline your coil winding processes, offering high efficiency and precision tailored for diverse industries. As a trusted manufacturer, we deliver exceptional quality machines that help reduce labor costs while enhancing productivity. The user-friendly design ensures smooth operation, making it accessible even for those new to coil winding. Built to withstand demanding environments, our machines offer robustness and durability for long-lasting performance. At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we provide comprehensive support from initial product selection to after-sales service, ensuring you make a confident investment in advanced technology that enhances your production capabilities. Contact us today to learn more about the advantages our Coil Winding Machine can bring to your business!

In-Depth Analysis of Coil Winding Machine Automatic Dominates From Concept to Delivery

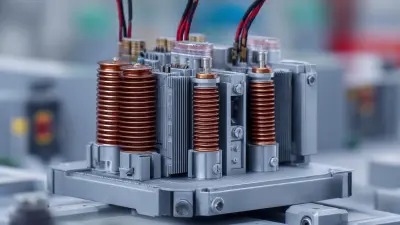

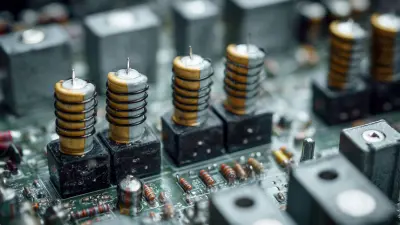

In the dynamic landscape of modern manufacturing, the coil winding machine has emerged as a cornerstone for industries ranging from electrical engineering to renewable energy. This in-depth analysis explores how automatic coil winding machines are transforming production processes, enhancing efficiency, and meeting the increasing global demand for high-quality, reliable components. By integrating advanced automation technologies, these machines minimize human error and reduce operational costs, allowing manufacturers to focus on innovation and production scalability.

From conceptual design to delivery, the evolution of coil winding machines reflects a commitment to technological advancement. Current models incorporate sophisticated features such as real-time monitoring, adaptive winding techniques, and seamless integration with automated production lines. These innovations not only optimize the winding process but also ensure precision and consistency, critical for applications such as electric motors, transformers, and inductors, thus addressing the growing needs of various sectors in the energy landscape.

As industries worldwide strive for sustainable and efficient manufacturing practices, embracing the capabilities of automatic coil winding machines is no longer optional but essential. With the right technology, businesses can drive productivity, meet stringent quality standards, and position themselves favorably within the competitive global market. The future of the machinery industry lies in such advancements, paving the way for a more empowered and energy-efficient tomorrow.

In-Depth Analysis of Coil Winding Machine Automatic Dominates From Concept to Delivery

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Automatic Tension Control | Maintains consistent tension during winding to prevent wire breakage. | Improved quality and reduced downtime. | Electric motors and transformers. |

| Programmable Logic Controller (PLC) | Allows for complex winding patterns and machine automation. | Increased production efficiency. | Home appliances and aerospace components. |

| Real-Time Monitoring | Tracks performance and alerts operators to issues instantly. | Minimized scrap rates and enhanced maintenance scheduling. | Medical devices and automotive parts. |

| Multi-Spindle Systems | Allows simultaneous winding on multiple spindles. | Higher throughput and better resource utilization. | Industrial motors and solenoids. |

| Customizable Die Sets | Easily changeable tools for different winding configurations. | Flexibility to meet diverse production requirements. | Consumer electronics and energy sectors. |

Champions of Coil Winding Machine Automatic Your End-to-End Solution Industry Giant

M

Michael Thompson

I am genuinely impressed with the product quality. Additionally, the after-sales support from their team was exceptional and they really knew their stuff.

13

August

2025

E

Ethan Clark

This product is of exceptional quality. The customer service staff were very professional and resolved my concerns efficiently.

24

August

2025

J

Jameson Lee

Very high-quality product! The after-sales support provided by their professionals was outstanding and very reassuring.

13

September

2025

A

Aria Lewis

Exceptional quality! The support staff demonstrated a commendable level of professionalism while assisting me.

20

September

2025

J

James Mitchell

Highly satisfied with my purchase. The product quality is exceptional, and the follow-up support was incredibly professional.

26

August

2025

E

Evelyn Collins

Excellent purchase! The product quality is outstanding, and the after-sales team handled my inquiries with great professionalism.

22

August

2025