Premium Custom Copper Wire for Transformer Winding - Top Suppliers & Factories Online

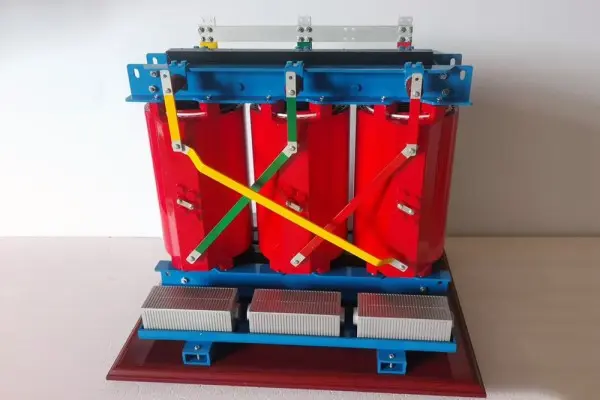

Our high-quality copper wire specifically designed for transformer winding sets a benchmark in the industry. We prioritize reliability and performance, ensuring that our meticulously manufactured wires cater to your unique requirements. With advanced technology and a skilled workforce, we guarantee that each wire adheres to stringent quality standards. Whether for automotive, energy, or electronics applications, our copper wires offer exceptional conductivity and durability. Partnering with WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD. ensures you receive not just a product, but a reliable solution tailored to your transformer winding needs. Contact us to learn more about our offerings and how we can assist your business.

Must-Know Tips For Copper Wire For Transformer Winding Your Trusted OEM Partner Guarantees Peak Performance

When it comes to transformer winding, understanding the nuances of copper wire selection is crucial for ensuring optimal performance. High-quality copper wire is essential in minimizing energy loss and maximizing durability in electrical applications. Here are some must-know tips for selecting the right copper wire for transformer winding to ensure your projects meet the highest standards.

First, consider the wire gauge and insulation types. The wire gauge directly influences the current-carrying capacity; therefore, it's essential to choose a gauge that can handle the expected load. Additionally, proper insulation protects against environmental factors and enhances safety. High-temperature rated insulations are particularly important in transformers where heat can accumulate. Secondly, ensure compliance with international standards and certifications, as this reflects on the wire’s reliability and performance.

Lastly, collaborating with a trusted OEM partner can make a significant difference. A knowledgeable partner provides access to advanced technologies and innovative solutions, ensuring that the copper wire used in your transformer winding meets the specifications necessary for peak performance. By prioritizing quality materials and expert support, you can drive efficiency and success in your projects, empowering the future of energy solutions.

Must-Know Tips For Copper Wire For Transformer Winding Your Trusted OEM Partner Guarantees Peak Performance

| Tip | Description | Advantages |

|---|---|---|

| Wire Gauge Selection | Choose the appropriate gauge based on current requirements and transformer size. | Ensures efficiency and prevents overheating. |

| Proper Insulation | Use high-quality insulation materials to coat the wire. | Enhances safety and reduces energy loss. |

| Winding Technique | Implement consistent winding techniques to avoid wire overlap. | Promotes uniform magnetic fields and efficient operation. |

| Heat Management | Incorporate cooling systems like air or oil to dissipate heat. | Prevents insulation breakdown and extends transformer lifespan. |

| Quality Control | Perform thorough inspections and testing of the winding process. | Ensures reliability and functional performance of transformers. |

Top 5 Copper Wire For Transformer Winding Guarantees Peak Performance Manufacturers You Can Rely On

R

Rachel Adams

The product quality speaks for itself. Coupled with fantastic after-sales service, it has made my purchase satisfying beyond measure.

31

August

2025

E

Emma Wilson

High-quality product, no doubt! The support team is truly dedicated and knowledgeable, making my experience smooth and enjoyable.

10

September

2025

E

Ella Allen

I’m thrilled with my purchase! Impressive quality and the support staff displayed exceptional professionalism throughout.

04

August

2025

A

Avery Martin

Unbelievable quality! The expertise and professionalism of their support team were evident when addressing my inquiries.

03

August

2025

S

Sofia Nelson

Excellent product! I was particularly impressed with the professionalism and responsiveness of their customer service team.

17

September

2025

B

Benjamin Turner

The quality is impressive, and the after-sales staff demonstrated remarkable professionalism in addressing my questions.

19

August

2025