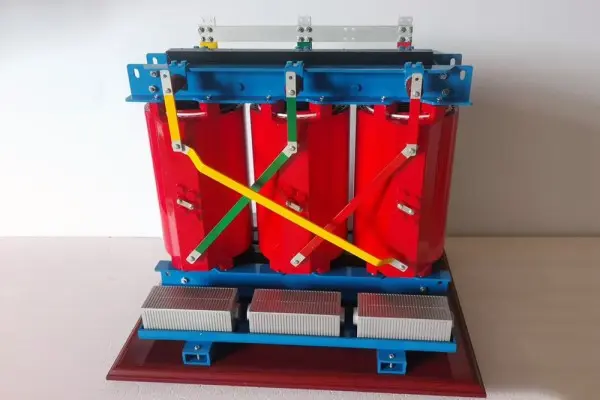

Core Assembly of Transformers: Best Discounts on Quality Products from Trusted Suppliers

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we provide high-quality Core Assembly of Transformer solutions tailored to meet various industry standards. Our modern factories in China utilize advanced technology and a team of skilled professionals committed to achieving precision and efficiency. Customer satisfaction is our top priority, and we ensure that every assembly is crafted with meticulous attention to detail. Whether you operate a small business or a large corporation, we offer customized solutions and outstanding after-sales support to enhance your operations. Rely on our expertise and let us be your trusted partner for success.

Step-by-Step Guide Core Assembly Of Transformer Dominates Stands Out

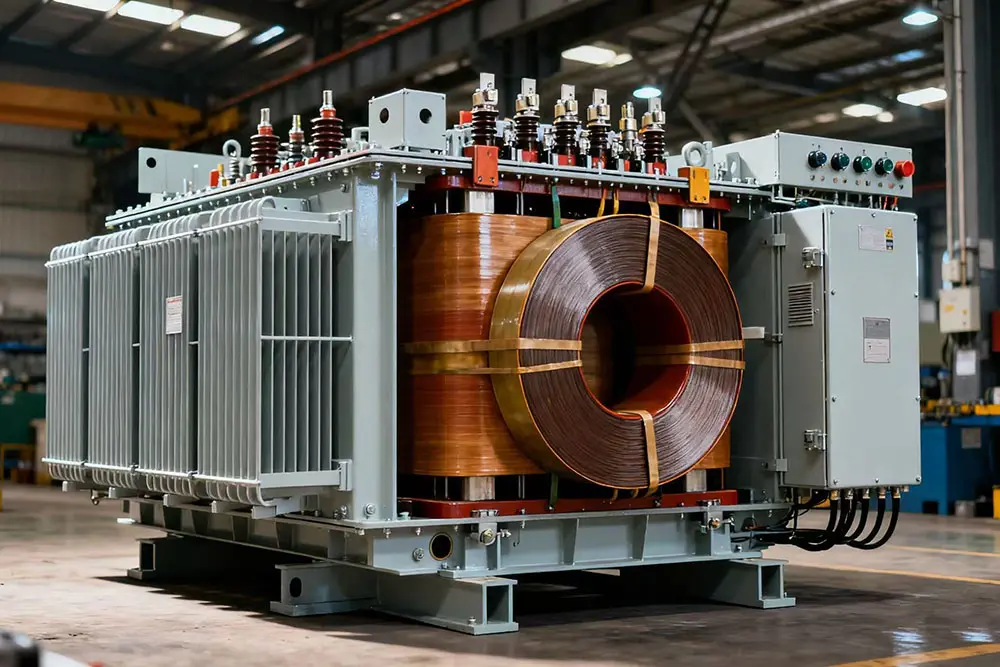

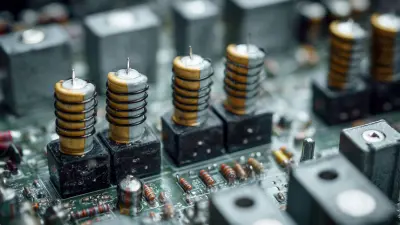

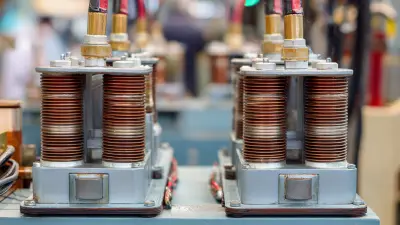

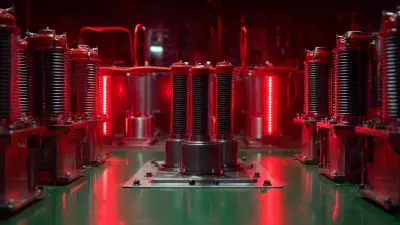

In the rapidly evolving machinery industry, the assembly of transformer cores plays a crucial role in ensuring reliable energy solutions. Understanding the intricacies of this process not only enhances operational efficiency but also positions companies at the forefront of innovation. This step-by-step guide delves into the core assembly of transformers, illuminating best practices and advanced techniques that can lead to superior performance and longevity of electrical machinery.

At the heart of transformer efficiency lies precision and quality in assembly. Begin by selecting high-grade materials that meet industry standards, ensuring optimal conductivity and durability. The careful layering of core materials should be executed with precision, with attention paid to minimizing losses and maximizing magnetic efficiency. Each step in the assembly process must be meticulously documented to establish a robust framework for quality control. As technology continues to advance, integrating automation tools can further streamline these processes, reduce human error, and cut production time.

As we look to the future of energy, understanding and mastering transformer core assembly becomes not just a technical challenge but a pathway to innovation. By focusing on meticulous assembly and embracing new technologies, businesses can empower themselves and their clients, thereby driving the entire industry forward. For global purchasers, partnering with forward-thinking suppliers who prioritize quality and innovation in their transformer solutions is essential for achieving long-term success in a competitive market.

Step-by-Step Guide Core Assembly Of Transformer Dominates Stands Out

| Step | Description | Time Required | Materials Needed | Safety Precautions |

|---|---|---|---|---|

| 1 | Gather all core assembly materials. | 30 minutes | Iron laminations, insulation tape, screws. | Wear gloves to avoid cuts. |

| 2 | Assemble the core stacks. | 1 hour | Core stacks, clamps. | Use protective goggles during assembly. |

| 3 | Install insulation around the core. | 45 minutes | Insulation material. | Ensure proper ventilation while working. |

| 4 | Secure the core with screws. | 30 minutes | Screws, screwdriver. | Handle tools carefully to avoid injuries. |

| 5 | Test the assembled core for efficiency. | 1 hour | Testing equipment. | Follow electrical safety guidelines. |

China Top Core Assembly Of Transformer From Concept to Delivery Your Trusted OEM Partner

M

Michael Thompson

I am genuinely impressed with the product quality. Additionally, the after-sales support from their team was exceptional and they really knew their stuff.

13

August

2025

E

Emma Wilson

High-quality product, no doubt! The support team is truly dedicated and knowledgeable, making my experience smooth and enjoyable.

10

September

2025

A

Ava Young

Absolutely love this product! The craftsmanship is remarkable and the customer service was very supportive and knowledgeable.

02

August

2025

N

Noah Baker

Top quality! The after-sales service team went above and beyond to ensure my satisfaction, demonstrating their professionalism.

10

September

2025

A

Addison Gray

Great quality product! The after-sales personnel were knowledgeable and reflected a very professional demeanor.

27

August

2025

O

Olivia Rodriguez

Very pleased with this product! The build quality is superb, and the support staff was attentive and knowledgeable, making my experience seamless.

09

September

2025