High-Performance Automatic Welding Machine for Custom Corrugated Sheets in Factories

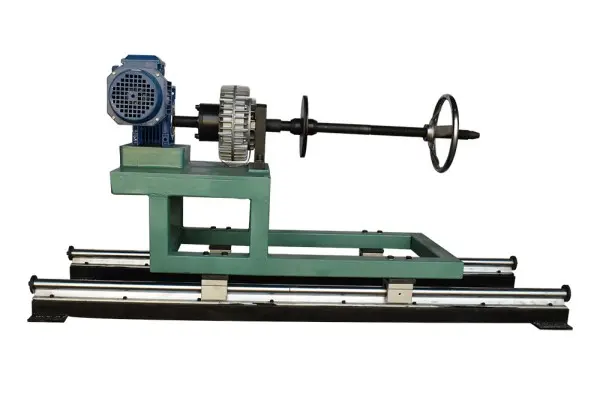

Elevate your corrugated sheet production with our state-of-the-art Corrugated Sheet Automatic Welding Machine. Engineered for efficiency and precision, this factory-direct equipment is customizable to seamlessly fit your specific operational needs. With a focus on high-quality craftsmanship, our machine enhances your welding process, streamlining operations while ensuring optimal results. At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we are dedicated to quality and customer care. Our experienced team is here to support you throughout the entire process, from selecting the ideal machine to providing ongoing after-sales assistance. By choosing our automatic welding solution, you gain a reliable partner committed to boosting your productivity and achieving your manufacturing goals.

Methods Corrugated Sheet Automatic Welding Machine Ahead of the Curve Service

In today's fast-paced manufacturing landscape, it's crucial for businesses to leverage advanced technology to stay ahead of competitors. The introduction of automatic welding machines for corrugated sheets represents a significant leap forward in efficiency and precision. These machines are designed to streamline production processes, reduce labor costs, and ensure consistent quality in welding applications. By automating this crucial aspect of manufacturing, companies can enhance their operational capabilities and meet the increasing demand for high-quality products.

The effectiveness of a corrugated sheet automatic welding machine lies in its ability to adapt to various materials and specifications while maintaining high standards. With features like adjustable welding parameters and integrated monitoring systems, these advanced machines allow manufacturers to achieve optimal results with minimal waste. As industries shift towards sustainable practices, investing in such innovative solutions not only boosts productivity but also aligns with the growing emphasis on environmental responsibility.

Additionally, the ability to provide responsive service and support is essential for businesses looking to invest in new machinery. A focus on customer-centric service ensures that procurement processes are smooth and that any operational challenges can be swiftly addressed. In a global market where efficiency and reliability are paramount, embracing cutting-edge technologies and superior service will undoubtedly empower manufacturers to forge a more prosperous future in the energy sector and beyond.

Methods Corrugated Sheet Automatic Welding Machine Ahead of the Curve Service

| Feature | Description | Benefits | Specifications |

|---|---|---|---|

| Automatic Feeding System | Ensures continuous material supply | Increases production efficiency | Compatible with various sheet sizes |

| Intelligent Control Panel | User-friendly interface for operation | Reduces operator error | 7-inch color display |

| High-Precision Welding | Delivers consistent weld quality | Improves product durability | Welds at temperatures up to 2000°C |

| Safety Features | Emergency stop and protective guards | Enhances worker safety | Meets international safety standards |

| Energy Efficiency | Low power consumption design | Reduces operational costs | Operates at 85% efficiency |

How To Identify Corrugated Sheet Automatic Welding Machine Outperforms the Competition Guarantees Peak Performance

L

Lucas Rivera

Highly recommend this product! The attention to detail in quality is great, and the staff was incredibly informative and helpful.

05

August

2025

C

Chloe Young

I love this product! The quality is fantastic, and the support from the team was impeccable and very professional.

23

September

2025

M

Matthew Turner

A fantastic find! The quality of this product is unrivaled, and the support from the team was very professional.

27

September

2025

A

Ava Carter

Superb quality! I also greatly appreciated the professionalism displayed by the customer service team.

16

August

2025

E

Ella Cook

Incredible quality on this item! The customer service staff were very knowledgeable and professional in addressing my needs.

28

September

2025

D

David Williams

Excellent quality and outstanding support! The team was very professional in answering my questions, making the whole experience smooth and enjoyable.

14

September

2025