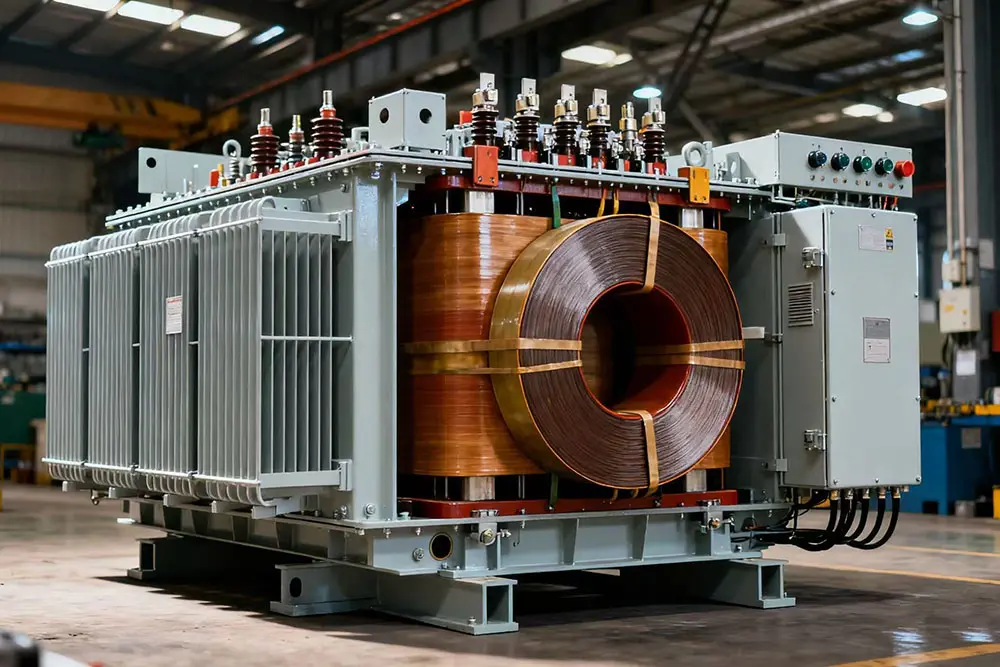

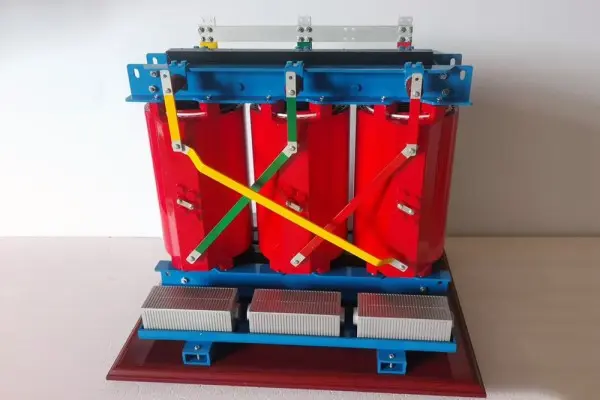

Top Dry Cast Resin Transformers from Leading Manufacturers and Factories

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we specialize in high-quality dry cast resin transformers tailored to meet the specific needs of industrial applications. Our custom solutions ensure optimal performance, adhering to strict safety and efficiency standards. With a commitment to innovation and durability, our transformers are ideal for clients in search of reliable electrical distribution systems. Each unit is meticulously crafted using advanced materials designed to withstand environmental factors. We prioritize collaboration with our clients to develop unique solutions that align with their requirements, ensuring that the transformers we deliver exceed expectations and contribute positively to their business success. Your satisfaction is paramount, and we are dedicated to providing the best in dry cast resin transformer technology.Methods To Dry Cast Resin Transformers Service Backed by Expertise Where Innovation Meets 2025

In the ever-evolving machinery industry, the need for reliable and innovative solutions is paramount, particularly in the realm of cast resin transformers. These transformers play a crucial role in ensuring the safety and efficiency of electrical systems, and finding effective methods for their maintenance and service is essential. As we look towards 2025, advancements in technology and expertise have paved the way for better strategies in drying cast resin transformers, which can significantly enhance their performance and longevity.

Methodologies such as controlled thermal cycling, desiccant drying, and the use of advanced monitoring systems not only optimize the drying process but also minimize downtime and improve operational efficiency. By integrating these techniques with a commitment to quality service and innovation, businesses can empower their energy solutions and meet the increasing demands of global markets. Ensuring that these transformers are dried and maintained by expert technicians further guarantees that they operate at their best, representing a smart investment for purchasers looking to future-proof their electrical systems.

As we transition into a new era in the machinery sector, embracing technological advancements and innovative practices will drive sustainable growth. This is especially true in the energy sector, where the careful servicing of cast resin transformers through expert-backed methods will not only safeguard electrical integrity but also contribute to a greener and more efficient future. The collective focus on quality and innovation will undoubtedly position businesses to thrive as they adapt to the challenges and opportunities of a dynamic marketplace.

Methods To Dry Cast Resin Transformers Service Backed by Expertise Where Innovation Meets 2025

| Method | Description | Expertise Level | Expected Outcome | Innovation Factor |

|---|---|---|---|---|

| Vacuum Drying | Utilizes vacuum technology to remove moisture from resin transformers. | High | Complete moisture removal, enhanced insulation properties. | Advanced |

| Thermal Drying | Involves heating to facilitate the evaporation of moisture. | Medium | Quicker drying times, lower risk of damage. | Moderate |

| Dehumidification | Uses dehumidifiers to reduce humidity levels around transformers. | Low | Improved air quality, prevention of future moisture issues. | Basic |

| Freeze Drying | Involves freezing the resin and then reducing the surrounding pressure. | Very High | Retains properties, minimal thermal stress. | Innovative |

Top 5 Dry Cast Resin Transformers Trusted by Pros Global Reach

A

Addison Gray

Great quality product! The after-sales personnel were knowledgeable and reflected a very professional demeanor.

27

August

2025

A

Anthony Mitchell

I am thoroughly impressed by the quality. The support staff was very knowledgeable and professional in all aspects.

18

September

2025

S

Sarah Thompson

This item exceeded my expectations! The quality is top-notch, and the support staff provided prompt and professional assistance when I had questions.

06

September

2025

Z

Zoe Robinson

I am thrilled with my purchase! The quality is exceptional, and the assistance from the customer service team has been top-notch.

02

August

2025

E

Emily Walker

This product stands out in terms of quality! The post-purchase service was equally impressive with knowledgeable representatives.

06

September

2025

M

Matthew Stewart

The quality is impressive! The customer support staff displayed unparalleled professionalism and expertise.

25

September

2025