Top Suppliers of Best Foil Winding for Transformers - Quality Products Available

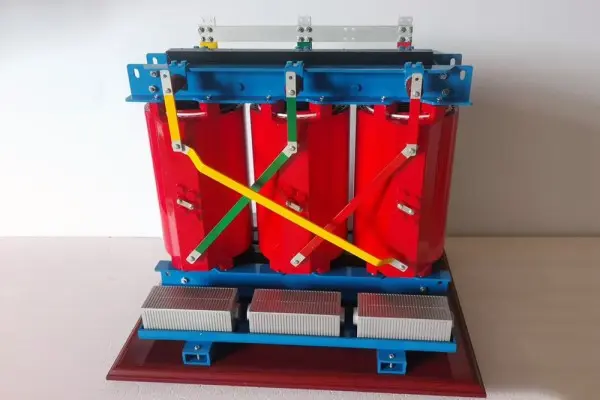

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we understand the importance of reliable and affordable foil winding solutions for transformers. Our high-quality products are specifically designed to enhance efficiency and durability in transformer applications, making them ideal for businesses focused on cost-effective options without sacrificing quality. We prioritize value and exceptional service, ensuring our competitively priced foil winding solutions meet the highest industry standards. Partner with us to power your business with dependable and tailored products that align with your requirements. With WUXI SHUHONG MACHINERY, you can trust that you're making a sound investment in your operational success.

Practical Methods To Foil Winding In Transformer Service Backed by Expertise Factory-Direct Excellence

In the ever-evolving machinery industry, the effective management of transformer service is critical for enhancing operational efficiency and reliability. One of the most pressing challenges faced by manufacturers is the issue of winding faults, which can lead to unscheduled downtime and increased maintenance costs. Understanding practical methods to address these challenges is essential for procurement professionals seeking to optimize their operations.

One approach to mitigating winding faults is through the implementation of advanced monitoring systems that leverage real-time data analytics. These systems can detect anomalies in transformer performance early, allowing for timely interventions before minor issues escalate into major failures. Additionally, investing in high-quality materials and components can significantly enhance the durability and resilience of transformers, reducing the likelihood of winding-related issues.

Moreover, partnering with experts who specialize in machinery technology can provide invaluable insights and support. Factory-direct excellence in service delivery ensures that procurement teams access the latest innovations and best practices in transformer management. By adopting a proactive stance, manufacturers can not only enhance their equipment's longevity but also contribute to a more sustainable energy future, ultimately positioning themselves as leaders in the global market.

Practical Methods To Foil Winding In Transformer Service Backed by Expertise Factory-Direct Excellence

| Method | Description | Advantage | Expert Insight |

|---|---|---|---|

| Winding Inspection | Regularly check winding insulation and connections for wear and damage. | Early detection of issues, prolongs winding life. | Routine inspections should be part of maintenance schedules. |

| Temperature Monitoring | Implement systems to monitor operating temperatures of windings. | Prevents overheating which can lead to winding failure. | Temperature trends should be analyzed periodically. |

| Vibration Analysis | Monitor vibrations in transformer operation to detect mechanical issues. | Identifies mechanical problems before they escalate. | Regular analysis recommended to maintain operational efficiency. |

| Insulation Resistance Testing | Conduct tests on insulation to ensure they meet required standards. | Ensures reliable performance and safety. | Testing frequency should align with manufacturer recommendations. |

Practical Strategies for Foil Winding In Transformer Where Innovation Meets 2025 Service Backed by Expertise

E

Ella Allen

I’m thrilled with my purchase! Impressive quality and the support staff displayed exceptional professionalism throughout.

04

August

2025

M

Matthew Carter

The quality is simply outstanding! The customer service was attentive and knowledgeable, making the purchase worthwhile.

16

August

2025

J

Jameson Lee

Very high-quality product! The after-sales support provided by their professionals was outstanding and very reassuring.

13

September

2025

J

Joshua Martin

I am very impressed with this purchase. The quality is the best I have encountered, and the after-sales service was both quick and efficient.

07

September

2025

J

Jacob Rivera

Very satisfied with this purchase! The quality is impressive, and the customer support was remarkably professional.

29

September

2025

E

Emily Johnson

The product exceeded my expectations in both performance and quality. The customer service team was highly professional and responsive to my inquiries.

18

September

2025