Custom Heavy Duty Coil Winding Machines – Expert Factory Solutions & Services

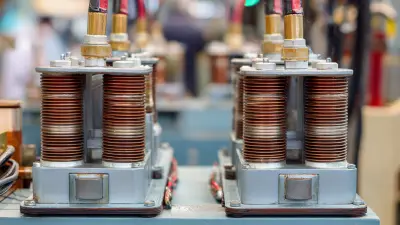

For businesses that demand top-tier coil winding solutions, we present our Heavy Duty Coil Winding Machine. Engineered for high efficiency and precision, this machine is a crucial addition to your production line. Originating from China, it offers exceptional performance and unrivaled durability. As a trusted supplier, we prioritize offering high-quality machinery tailored to your operational needs. Our commitment extends beyond just the product; we provide robust support through installation and ongoing maintenance. With WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., you gain a reliable partner dedicated to enhancing your manufacturing capabilities and driving your success.

Best Methods To Heavy Duty Coil Winding Machine Custom Solutions, Manufacturer

In the ever-evolving machinery industry, heavy-duty coil winding machines have become essential for various manufacturing applications. These machines are designed to meet high production demands while ensuring precision and efficiency. As global procurement becomes more competitive, finding a manufacturer that offers customized solutions tailored to specific needs is crucial. Implementing the best methods for coil winding can significantly enhance operational efficiency, reduce waste, and ultimately lead to increased profitability.

When selecting a manufacturer for heavy-duty coil winding machines, it’s vital to prioritize those that emphasize technological innovation and superior service. Custom solutions can be designed to accommodate unique production requirements, including varying coil sizes, insulation types, and winding patterns. A manufacturer with expertise in both electrical and plastic machinery can leverage advanced technologies to optimize the winding process, integrating automation and real-time monitoring systems that enhance productivity and reliability.

Understanding the latest advancements in coil winding technology is key to making informed procurement decisions. Features such as programmable control systems, adaptive winding techniques, and energy-efficient designs can set apart a world-class coil winding machine. By focusing on suppliers that not only deliver high-quality machinery but also provide ongoing support and upgrades, businesses can ensure they are equipped to meet the challenges of the future energy landscape and maintain a competitive edge in their respective markets.

Best Methods To Heavy Duty Coil Winding Machine Custom Solutions, Manufacturer

| Method | Description | Applications | Advantages | Limitations |

|---|---|---|---|---|

| Manual Winding | Hand-operated coil winding process. | Low-volume custom projects. | Cost-effective for small runs. | Time-consuming and labor-intensive. |

| Automated Coil Winding | Use of machines for precision winding. | High-volume production, industrial applications. | Consistency and speed in production. | Higher initial investment cost. |

| Multi-Spindle Winding | Winding with multiple spindles simultaneously. | Complex coil designs, electrical components. | Increases output and efficiency. | Complex setup and machinery required. |

| Robotic Winding | Use of robotic systems for precision and speed. | Highly technical applications, advanced engineering. | High precision, reduced labor costs. | Requires skilled programming and robotics maintenance. |

Decoding Heavy Duty Coil Winding Machine Trusted by Pros Where Service Meets Innovation

M

Madison Price

Very satisfied with the quality of the product! The after-sales support team was professional and very efficient.

30

August

2025

I

Isaac Hall

I am very pleased with this purchase! The excellent quality combined with the helpful customer service made it worthwhile.

31

July

2025

N

Natalie Parker

Top-notch quality! Their after-sales professional staff was incredibly responsive and made the whole process seamless.

06

August

2025

J

Jackson Martinez

Superb quality! The after-sales service provided was exemplary, with very professional and friendly staff.

31

August

2025

M

Matthew Turner

A fantastic find! The quality of this product is unrivaled, and the support from the team was very professional.

27

September

2025

J

Jacob Rivera

Very satisfied with this purchase! The quality is impressive, and the customer support was remarkably professional.

29

September

2025