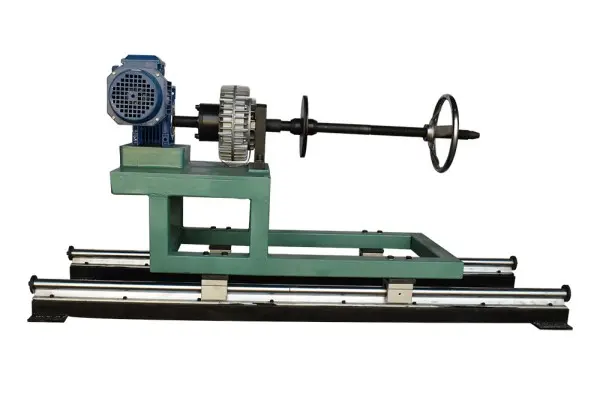

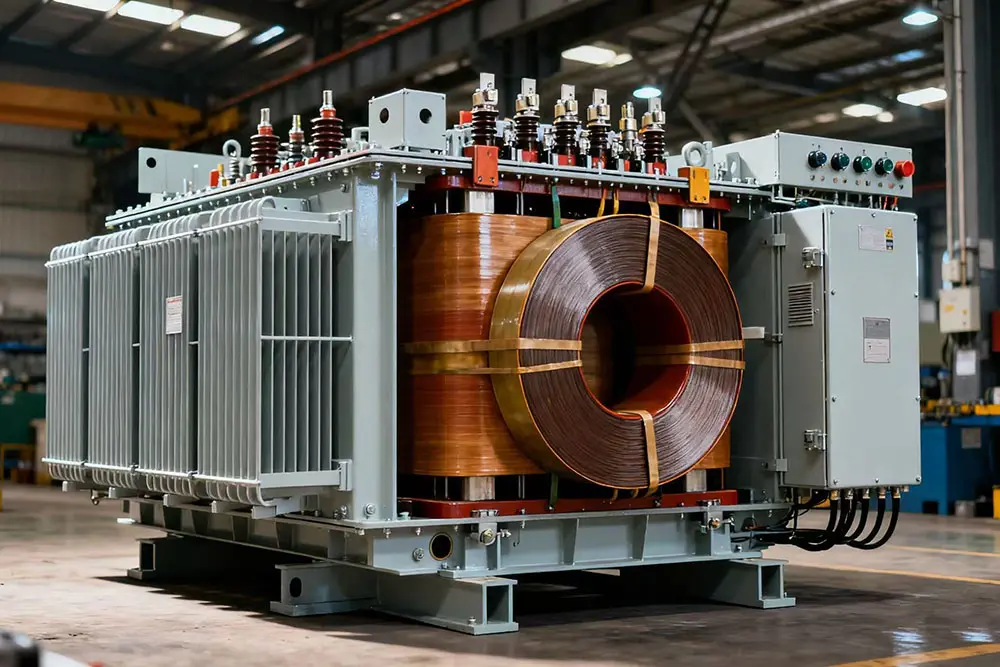

High Voltage Coil Winding Solutions from Top Industry Manufacturers and Services

For exceptional high voltage coil winding solutions, WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD. stands out as a premier choice. Their extensive product range combines precision and durability, making them ideal for various coil winding applications. The machinery features robust designs and cutting-edge technology that consistently meet top industry standards. WUXI SHUHONG is a trusted supplier known for delivering high-quality products that enhance efficiency and reliability in coil winding processes. Partnering with them is an excellent decision for any business need!

Tips & Tricks for High Voltage Coil Winding in 2025 Your Trusted OEM Partner

As we venture into 2025, the demand for high voltage coil winding technologies is experiencing exponential growth, driven by the ongoing transformation in the energy sector. Manufacturers looking to excel in this niche must prioritize advanced methodologies and robust machinery capable of handling the complexities of high voltage applications. Implementing cutting-edge techniques not only improves efficiency but also enhances product reliability, ultimately satisfying the rigorous requirements of global buyers.

To stay competitive, focus on key aspects such as precision in winding processes and the integration of automation. Utilizing advanced software and machine learning for real-time monitoring can significantly minimize human error and maximize output quality. Furthermore, embracing sustainable practices in your production processes can resonate well with environmentally-conscious partners and consumers, thereby enhancing your brand reputation in the global market.

Collaboration with a reliable OEM partner can provide access to innovative technology and expertise, ensuring your operations are not only efficient but also future-proof. Leveraging these relationships can help navigate the evolving landscape of energy demands, positioning your business for long-term success in the dynamic machinery industry.

Tips & Tricks for High Voltage Coil Winding in 2025 Your Trusted OEM Partner

| Tip No. | Tip/Trick | Description | Expected Benefits |

|---|---|---|---|

| 1 | Use Quality Insulation Material | Select high-grade insulation materials to prevent breakdowns. | Increases coil longevity and safety. |

| 2 | Consistent Tensioning | Maintain constant tension during winding for even layers. | Improves coil uniformity and performance. |

| 3 | Opt for Automated Winding Machines | Utilize modern machinery for precise and rapid winding. | Enhances production efficiency and reduces errors. |

| 4 | Implement Temperature Monitoring | Monitor temperatures during winding to prevent overheating. | Protects insulation and improves reliability. |

| 5 | Regular Maintenance Checks | Schedule regular maintenance on equipment and tools. | Prolongs equipment life and ensures high-quality output. |

Top Picks For High Voltage Coil Winding Dominates Now Trending

D

David Martinez

The quality is top-notch! Their after-sales service is also commendable; the staff showed great expertise in handling my queries.

14

September

2025

R

Rachel Adams

The product quality speaks for itself. Coupled with fantastic after-sales service, it has made my purchase satisfying beyond measure.

31

August

2025

Z

Zoe Cooper

Absolutely love this product! The quality is fantastic and the after-sales service staff were incredibly professional.

06

September

2025

O

Oliver Wright

The quality is impressive! I was particularly impressed by the professionalism and expertise of their after-sales staff.

03

September

2025

J

Jessica Davis

The product quality is first-class! Moreover, the aftercare support was very responsive, making me feel valued as a customer.

07

August

2025

L

Lucas Scott

A great addition to my purchases! The quality is impressive, and the customer service was responsive and highly professional.

28

August

2025