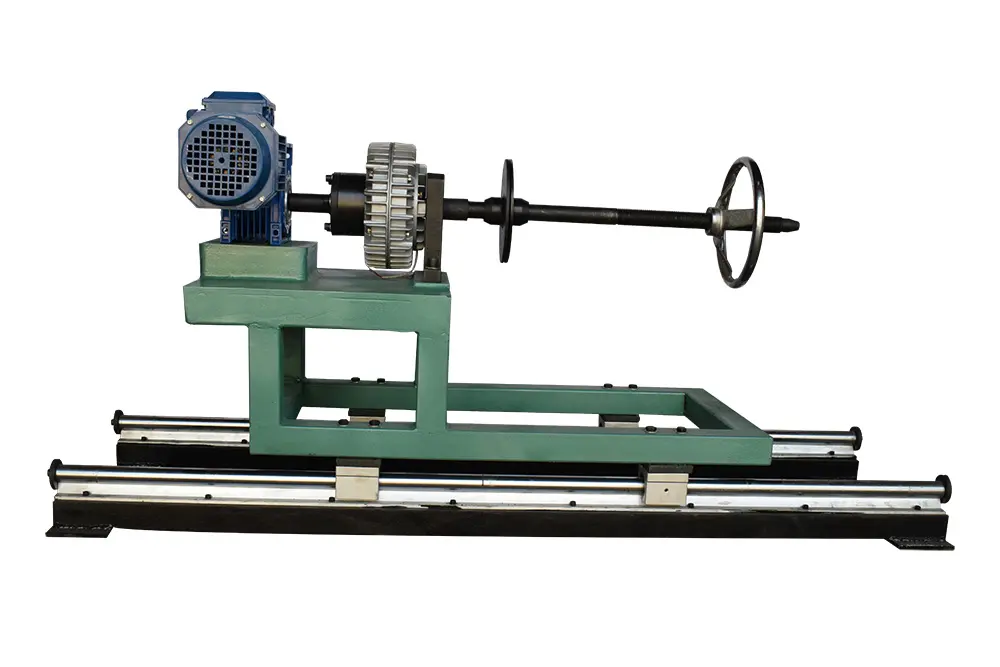

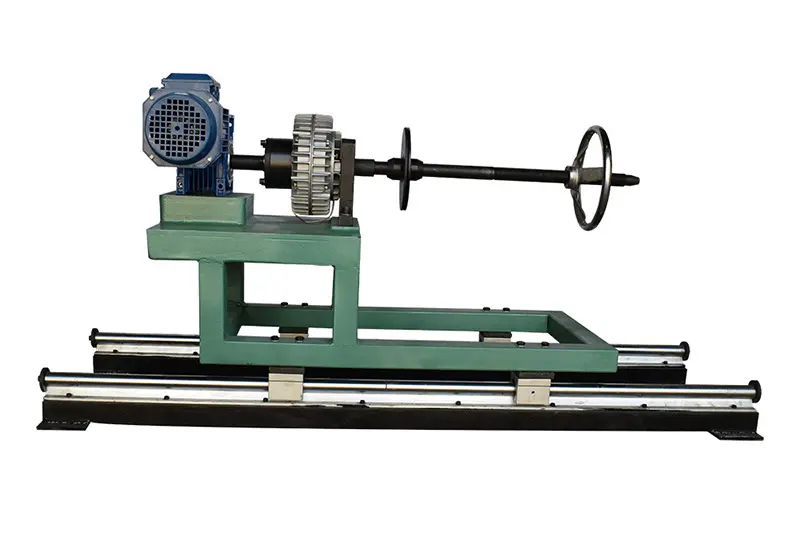

High Voltage Tension Pay-off Stand for Power Cables

Product Specification

| Code | SHZL-50N SHZL-100N |

| Max Load Capacity | 100kg |

| Tray Height | ≤400MM |

| Tray Diameter | ≤500MM |

| Moving Length | ≤800MM |

| Tension Control Range | 50 N - 5000 N (adjustable in 1 N increments, compatible with small and large cross-section wires) |

| Tension Accuracy | ±1% of set value (closed-loop control via tension sensor, ensuring stable tension during wire pay-off) |

| Wire Adaptation - Round Wire | Diameter: 0.5 mm - 50 mm (compatible with enameled copper wire, enameled aluminum wire) |

| Wire Adaptation - Flat Wire | Cross-section: 5 mm×10 mm - 20 mm×50 mm (suitable for paper-insulated flat wire, bare flat copper wire) |

| Wire Feeding Speed | 0.5 m/min - 10 m/min (stepless speed regulation, synchronized with transformer coil winding machine) |

| Speed Stability | ±0.2 m/min (avoids wire jitter or uneven arrangement during winding) |

Advantages

1. Precise Tension Control: It can stably adjust the cable pay-off tension, avoiding abrasion, deformation, or breakage of cables caused by uneven tension, thus ensuring the quality of high-voltage transmission line laying.

2. High Durability: Made of high-strength and corrosion-resistant materials, it can stably withstand heavy cable loads. It is suitable for outdoor and complex construction sites, not easy to be damaged during long-term use, and reduces equipment maintenance costs.

3. High Safety: Equipped with an anti-slip base to prevent the pay-off stand from tipping over during operation. It is matched with flexible tension-adjustment components, which can be fine-tuned in real time according to construction needs, reducing operational risks and improving work safety.

4. High Compatibility: Compatible with high-voltage cables of multiple specifications, it eliminates the need for frequent equipment replacement, meets the needs of different transmission line construction scenarios, and enhances the practicality of the equipment.

5. Improved Construction Efficiency: Through stable cable pay-off performance, it reduces cable jamming and rework, shortens the construction cycle, and helps promote the efficient progress of high-voltage power transmission projects.

Product Display

Application

1. High-voltage coil winding for power transformers: This system controls conductor tension to ensure coil tightness, adapting to various wire specifications, including round enameled wire and flat paper-wrapped wire. It utilizes pancake and layer winding processes to meet the coil winding requirements of 10kV-1000kV power transformers.

2. Specialty transformer coil winding: This system is suitable for the regular winding of epoxy-cast coils for dry-type transformers, controls conductor tension for multiple windings in rectifier transformers to ensure insulation isolation, and utilizes pre-bending and guiding of flat wire for traction transformers to prevent warping during winding.

3. Multi-conductor parallel winding: This system achieves balanced tension control for the simultaneous winding of 2-8 conductors, adapts to transposed conductor winding, prevents loose strands and misalignment, and meets the low-loss winding requirements of large transformers.

4. Automated production linkage: This system integrates with winding machines, cutting machines, and insulation paper wrapping machines to achieve an integrated process of pay-off, winding, insulation wrapping, and cutting. It also records tension data and provides abnormality warnings to ensure production efficiency and stable quality.