Industrial-Grade 3D Triangular Rolled Core Transformer for Power Supply Systems

S13 and S11 Product Specification

| Rated capacity KVA | Voltage combination and tap range | Connection group symbol | No-load loss | No-load current | Load loss | Short-circuit impedance % | |||

| High pressure KV | Tapping range of high voltage % | Low pressure KV | S13 | S11 | |||||

| 30 | 6 6.3 10 10.5 11 |

±5 | 0.4 | Dyn11 Yzn11 Yyn0 | 80 | 100 | 0.30 | 630/600 | 4.0 |

| 50 | 100 | 130 | 0.24 | 910/870 | |||||

| 63 | 110 | 150 | 0.23 | 1090/1040 | |||||

| 80 | 130 | 180 | 0.22 | 1310/1250 | |||||

| 100 | 150 | 200 | 0.21 | 1580/1500 | |||||

| 125 | 170 | 240 | 0.20 | 1890/1800 | |||||

| 160 | 200 | 280 | 0.19 | 2310/2200 | |||||

| 200 | 240 | 340 | 0.18 | 2730/2600 | |||||

| 250 | 290 | 400 | 0.17 | 3200/3050 | |||||

| 315 | 340 | 480 | 0.16 | 3830/3650 | |||||

| 400 | 410 | 570 | 0.16 | 4520/4300 | |||||

| 500 | 480 | 680 | 0.16 | 5410/5150 | |||||

| 630 | Dyn11 Yyn0 | 570 | 810 | 0.15 | 6200 | 4.5 | |||

| 800 | 700 | 980 | 0.15 | 7500 | |||||

| 1000 | 830 | 1150 | 0.14 | 10300 | |||||

| 1250 | 970 | 1360 | 0.13 | 12000 | |||||

| 16000 | 1170 | 1640 | 0.12 | 14500 | |||||

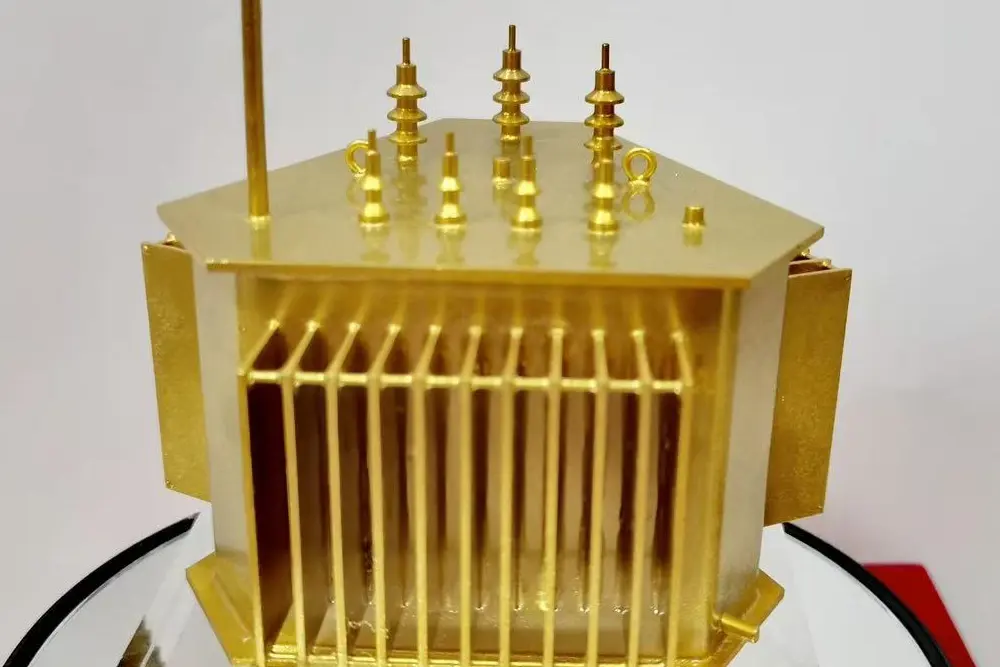

Detail display

Applications of 3D Triangular Wound Core Transformer

Power Distribution Networks: Integrated into urban and rural medium/low-voltage power grids, it efficiently steps down high-voltage electricity to usable levels for residential communities, ensuring stable power supply for households (lighting, appliances) with ultra-low energy loss.

Industrial Facilities: Deployed in manufacturing workshops (machinery, electronics, textiles) and industrial parks, it provides reliable voltage regulation to support continuous operation of production equipment, minimizing power fluctuations that affect precision processes.

Commercial Buildings: Used in shopping malls, office towers, and hotels to distribute power for HVAC systems, elevators, lighting, and commercial appliances, with its low-noise design suiting indoor public environments.

Renewable Energy Systems: Paired with solar photovoltaic or small wind power plants, it converts unstable renewable energy output into grid-compatible electricity, facilitating smooth integration into the main power network.

Product Display

Advantages

1. Optimization of magnetic circuit:

● There is no joint between the three dimensional volume of the core layer, uniform distribution of the magnetic circuit. There is no obvious high resistance area and no distortion of the magnetic flux density of the joint.

● The direction of the magnetic flux is completely consistent with the orientation of the silicon steel sheet.

● The length of the three-phase magnetic circuit is exactly the same, and the length of the three-phase magnetic circuit is the shortest.

● The three-phase magnetic circuit is completely symmetrical, and the three air current is completely balanced.

2. Low loss, energy savings remarkable:

● The magnetization direction of three-dimensional rolled iron core is completely consistent with the direction of rolling silicon steel sheet, even magnetic flux distribution throughout the uniform, no high resistance region, no obvious distortion of the magnetic flux density of joints. While using same material, compared with laminated core. The wound core's iron loss can be reduced from 1.3-1.5 to 1.05. This feature can make the core loss reduce about 10-20%.

● Due to special three-dimensional structure, the materials used in iron core yoke can be 25% off than traditional laminated core, the weight of angle core accounted about 6% of the total weight.

● Shearing of silicon steel sheet processing will lead to the deterioration of magnetic conductivity. Three-dimensional wound iron is annealing treated in high temperature(800 DEG C)nitrogen vacuum, not only eliminates the core mechanical stress, also refines the magnetic domain of silicon steel sheet, thus improves the secondary recrystallization of silicon steel sheet. So the performance of silicon steel sheet is much better than the ex- factory performance.

● Test reports that the three dimensional transformer’s no-load loss is 25-35% lower than the national standard, the maximum load current can be reduced by 92%.

3. Low noise:

The source of noise caused by the vibration of the transformer body is:

● The magnetic expansion of the silicon steel sheet causes the vibration of the iron core, then the noise is produced.

● The electromagnetic attraction between the joint of the silicon steel sheet and the lamination is caused by leakage, which causes the core vibration and noise.

● The working magnetic density of the transformer is too high, close to or reach saturation point, too large leakage results in noise.

● The three-dimensional wound iron core is made by dedicated uninterrupted, continuous tightly rolling silicon steel strip in the core winding machine. There is no seams, so it won t make noses like laminated cores. At the same time, the three-phase magnetic circuit and the magnetic flux is completely symmetrical, the working magnetic density design is reasonable, therefore the product noise is greatly reduced.

4. High overload ability:

● The product itself has very low heat: the winding core transformer's no-load loss, no-load current are both very small, so the product itself is very low heated.

● Three-phase coil is like three chimney delta shaped, so an airway chimney is formed in the coil. The core yoke has a temperature difference of 30-40℃, which causes strong cross-ventilation. Cold air goes up to the warm side, the heat is radiated from the inner bevel of upper yoke.

5. High overload ability:

● The product itself has very low heat: the winding core transformer's no-load loss, no-load current are both very small, so the product itself is very low heated.

● Three-phase coil is like three chimney delta shaped, so an airway chimney is formed in the coil. The core yoke has a temperature difference of 30-40℃, which causes strong cross-ventilation. Cold air goes up to the warm side, the heat is radiated from the inner bevel of upper yoke.

6. Compact structure, small location:

The special-designed three-dimensional core makes compact structure products reasonable layout, the transformer body occupied is 10-15% less than traditional products, body height 10-20%. If installed in the substation box, the substation box can deduce nearly 1/4.

7. Anti-theft:

The copper coil is wounded onto the iron. The copper coil is hard to taken out without big professional equipment.