Industrial High & Low Voltage Foil Winding Equipment for Transformers

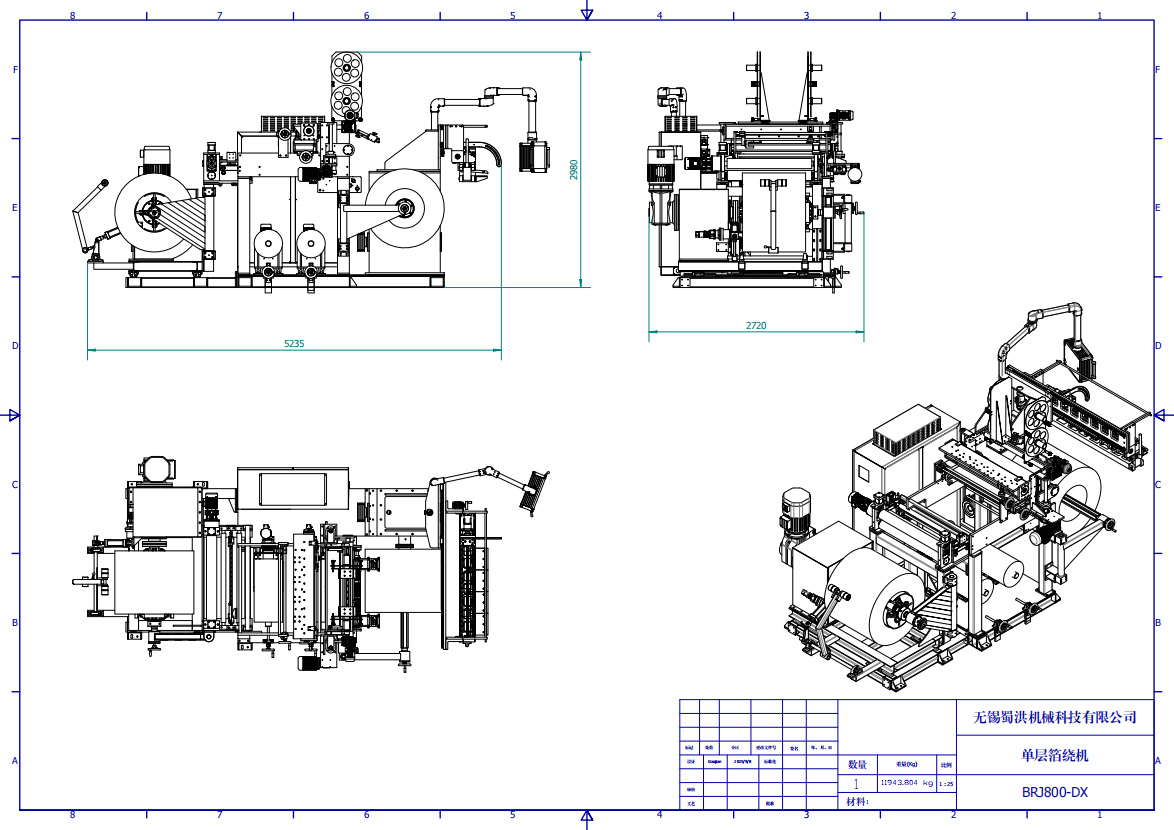

Product Drawing

Product Specification

| Code | SH-600 | SH-800 | SH-1100 | SH-1400 |

| Coil outer diameter | 150-750mm |

150-850mm |

200-1000mm | 200-1000mm |

| Foil width | 100-600mm |

150-800mm |

200-1100mm | 300-1400mm |

| Foil layers | Single or double | |||

| Foil thickness | Copper Cu:0.3-2.5mm Aluminium Al: 0.5-3.0mm | |||

| Winding speed | 0-30r/min |

0-30r/min |

0-20r/min | 0-20r/min |

| Max tension of foil | 6000N | 8000N | 10000N | 14000N |

| Welding speed | 0-0.5 m/min | |||

| Correction precision | ±0.5mm | |||

| Welding method | TIG or cold pressure welding | |||

Detail display

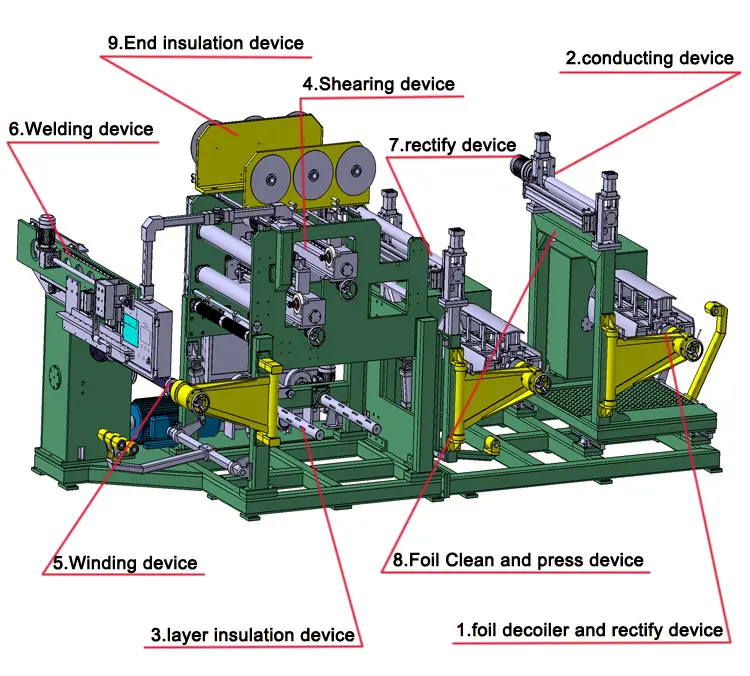

Structure

Advantages

1. Adopting motor initiative supplying tension advanced method , stable tension , there is stable tension in foil winding, stopping and foil returning . It can avoid loosen situation when the tension lost in windin.

2. Winding speed reducer is turbine shaft reducer , it can keep main shaft auto - locked whenever power on or power off status.

3. Correction system using photoelectric analog sensors , it is not meeting with foil edge , both thick and thin foil are accepted.

4. Foil tension, layer insulation tension, coil parameters , winding status and other data , all of them can be set and showed on screen, easy for operating, accurately and intuitively.

5. Equipment is controlled by PLC and touch screen, less fault of whole machine, no friction noisy, stable working, high working efficiency.

Application of Foil Winding Machine

Applied in the field of power transformer manufacturing

● High-voltage power transformers: Used in 110kV and above power transmission and transformation systems (such as substations and inter-regional power grids), these transformers produce high-voltage windings with copper/aluminum foil conductors to meet high-voltage, low-loss power transmission requirements.

● Medium- and low-voltage distribution transformers: Suitable for 10kV and below distribution networks (such as urban power grids and industrial park distribution), these transformers produce low-loss, high-efficiency foil coils to ensure stable power supply to end users.

● Specialty power transformers: These include dry-type power transformers (used in fire-resistant environments such as high-rise buildings and subways) and oil-immersed power transformers (used in large outdoor substations). Their foil windings must be wound using this equipment.

Applied in the field of industrial special reactors/transformers

● Filter reactors: Used in high-power industrial applications such as steel and chemical industries, they filter grid harmonics and protect precision equipment. Their foil windings require high insulation strength and overload resistance.

● Rectifier transformers: Suitable for industrial production lines requiring DC power, such as electrolytic aluminum and electroplating. High-current-resistant foil coils are wound to ensure stable operation of the rectifier system.

● Electric furnace transformers: Used in industrial furnaces (such as arc furnaces and induction furnaces), they produce foil windings capable of withstanding short-term high loads to meet the power needs of high-temperature smelting.

Applied in the fields of new energy and energy storage equipment

● New energy transformers: These include wind turbine box transformers (connecting wind turbines to the grid) and photovoltaic inverter transformers. Their foil coils must withstand harsh outdoor environments (low temperatures, wind and sand) and exhibit low losses.

● Energy Storage Converter (PCS) Inductors: These are used in energy storage power plants to wind foil windings for filter and boost inductors in energy storage systems, ensuring efficient conversion between energy storage and release.

● Charging Pile Transformers: These are designed for fast-charging charging piles and feature compact, high-power-density foil coils to meet the power needs of electric vehicles for rapid charging.