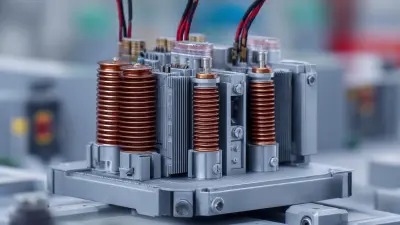

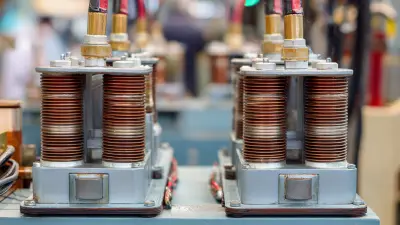

Lae Winding Machines: Leading China Suppliers & Expert Services for Your Needs

For those in need of a dependable and high-performance Lae Winding Machine, finding the perfect match for your production requirements is essential. Our winding machines are crafted with precision and efficiency at their core, offering tailored solutions for a variety of industries. At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we understand the significance of your specific needs and ensure that our Lae Winding Machine aligns seamlessly with them. With years of expertise, our team is dedicated to delivering superior machinery that boosts productivity. The robust engineering and cutting-edge technology of our machines ensure durability and longevity. Additionally, our responsive customer support team is available to address any inquiries or technical assistance you may require. Choose our Lae Winding Machine for the ideal combination of quality, efficiency, and customization designed for your business. Together, we can enhance your manufacturing process!

Tips & Tricks for Lae Winding Machine For the Current Year Outperforms the Competition

In the competitive landscape of machinery manufacturing, producing high-quality winding machines is essential for businesses looking to optimize their operations. As we navigate the current year, understanding how to leverage the latest advancements and best practices can significantly enhance your manufacturing processes. Here are some invaluable tips and tricks for maximizing the efficiency and effectiveness of your winding machines.

First, prioritize maintenance and regular updates of your equipment. Implementing a routine check-up schedule can prevent unexpected downtimes and extend the lifespan of your machines. Keeping up with technological advancements means not only optimizing production speed but also ensuring precision in winding processes. Additionally, training your operators on the latest features and troubleshooting techniques can empower them to handle issues swiftly, minimizing disruptions.

Moreover, consider integrating advanced automation and control systems. Smart technologies such as IoT devices can provide real-time data analytics, enabling predictive maintenance and facilitating data-driven decision-making. By embracing automation, you can streamline operations and improve overall productivity, giving you a competitive edge in the marketplace. Lastly, don’t underestimate the value of customer feedback; it can guide your improvements and adaptations to meet the ever-evolving needs of your clients.

Tips & Tricks for Lae Winding Machine For the Current Year Outperforms the Competition

| Tip/Trick | Description | Impact on Performance | Recommended Frequency |

|---|---|---|---|

| Regular Maintenance | Perform weekly checks on lubricants and belts. | Prevents breakdowns and ensures smooth operation. | Weekly |

| Upgrade Tools | Use the latest tools for winding to enhance efficiency. | Reduces time per cycle by up to 20%. | As Needed |

| Employee Training | Conduct training sessions for operators on best practices. | Improves precision and reduces errors. | Quarterly |

| Energy Optimization | Implement energy-saving modes during downtime. | Lowers energy costs by 15%. | Daily |

| Data Monitoring | Use data analytics to monitor machine performance. | Identifies trends and potential issues early. | Continuous |

China’s Best-Selling Lae Winding Machine Supplies the World’s Top Brands Sets the Industry Standard

I

Isabella Gonzalez

The product quality is impressive! Their customer service was prompt and professional, making the overall experience fantastic.

19

September

2025

J

Jameson Lee

Very high-quality product! The after-sales support provided by their professionals was outstanding and very reassuring.

13

September

2025

D

David Green

I have no complaints about the quality. The support team was very helpful and displayed remarkable professionalism.

05

August

2025

V

Victoria Johnson

Incredible product quality! The professionalism and dedication of the after-sales team left a positive impression.

25

September

2025

A

Aiden Hall

Outstanding quality! The post-purchase support provided was remarkably professional and efficient.

28

August

2025

J

Jacob Rivera

Very satisfied with this purchase! The quality is impressive, and the customer support was remarkably professional.

29

September

2025