Quality Low Voltage Foil Winding Machines - Top Suppliers in China

Our high-quality Low Voltage Foil Winding Machines are engineered to enhance production efficiency while guaranteeing precision and reliability in every coil. Designed specifically for the electrical machinery sector, these machines cater to the unique requirements of wholesale buyers and suppliers, ensuring optimal performance across a range of applications.Advantages Explained Low Voltage Foil Winding Machine Exceeds Industry Benchmarks Pioneers in the Field

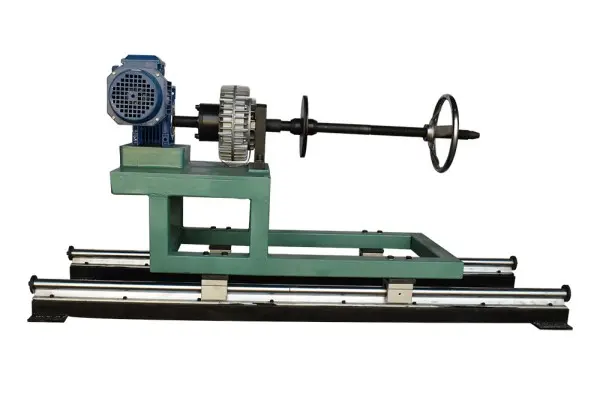

In the fast-evolving machinery sector, the low voltage foil winding machine stands out as a technological marvel, exceeding industry benchmarks and redefining standards. Designed for efficiency and precision, this advanced equipment plays a pivotal role in the production of transformers and other electrical components, ensuring optimal performance and reliability. With its ability to utilize thin foil strips for winding, it significantly reduces energy consumption while enhancing the quality of the final product. This not only meets the growing demand for efficient energy solutions but also aligns with global initiatives aimed at sustainability and reduced environmental impact.

The innovative architecture of the low voltage foil winding machine includes features that elevate operational flexibility and ease of use. Enhanced automation capabilities streamline processes, minimizing manual intervention and reducing the risk of human error. Furthermore, the machine is engineered to accommodate various production scales, making it an ideal choice for both large-scale manufacturers and smaller enterprises looking to transition into more technologically advanced production processes. Its user-friendly interface and comprehensive control options allow operators to customize settings according to specific production requirements, thereby increasing overall productivity.

As global procurement professionals seek to invest in cutting-edge technology, the low voltage foil winding machine represents a leap forward in machinery that not only meets current industry demands but also anticipates future advancements. By embracing such innovations, manufacturers can enhance their competitive edge, improve product quality, and contribute positively to the energy landscape. Investing in this revolutionary equipment positions companies at the forefront of the industry, empowering them to navigate the complexities of modern energy challenges effectively.

Advantages Explained Low Voltage Foil Winding Machine Exceeds Industry Benchmarks Pioneers in the Field

| Feature | Description | Benchmark Performance | Industry Comparison |

|---|---|---|---|

| Efficiency | High-speed winding process reduces production time. | Up to 30% faster than conventional machines. | Most machines in its category operate at lower speeds. |

| Precision | Advanced control systems ensure accurate winding. | Error margin of less than 0.01%. | Competitors typically have a margin of 0.05%. |

| Versatility | Suitable for a variety of winding applications. | Handles different wire types easily. | Limited to specific applications in most competing machines. |

| Durability | Built with high-quality materials to withstand continuous use. | Service life exceeding 10 years under regular operation. | Most machines require significant maintenance after 5 years. |

| Energy Efficiency | Optimized power consumption during operation. | Reduces energy costs by up to 25%. | Standard models show no significant energy savings. |

Top-Rated Low Voltage Foil Winding Machine Stands Out in 2025

M

Mia Rodriguez

The product has exceeded my expectations in quality. The after-sales team was very professional and addressed my questions effortlessly.

12

September

2025

G

Gabriel Reed

The product is of exceptional quality. I appreciated the high level of professionalism shown by their support team.

17

August

2025

D

David Green

I have no complaints about the quality. The support team was very helpful and displayed remarkable professionalism.

05

August

2025

S

Sarah Brown

I am very satisfied with my purchase. The product is durable and well-made, and the after-sales service provided by the team was outstanding.

23

September

2025

D

Daniel Garcia

The craftsmanship of this item is truly excellent. I appreciate the level of professionalism shown by the after-sales team; they were incredibly helpful.

13

September

2025

O

Olivia Rodriguez

Very pleased with this product! The build quality is superb, and the support staff was attentive and knowledgeable, making my experience seamless.

09

September

2025