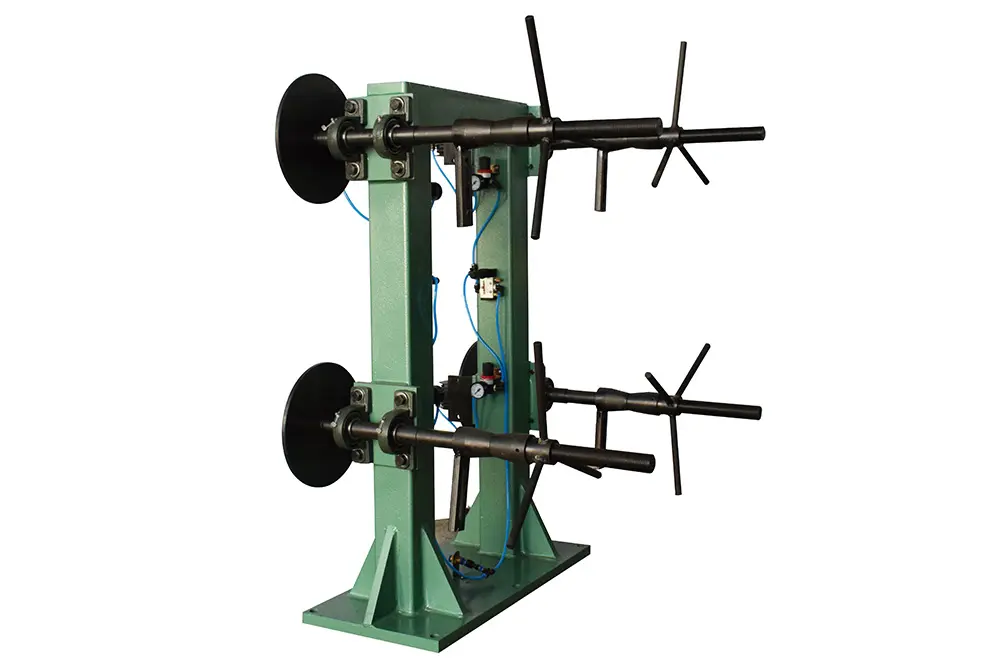

Low-Voltage Tension Pay-Off Stand for Low-Voltage Transformer Coils

Product Specification

| Code | SHZL-4 |

| Max Load Capacity | 200kg |

| Tray Height | ≤400MM |

| Tray Diameter | ≤600MM |

| Tension Control Range | 5 N - 500 N (adjustable in 1 N increments, for micro-tension needs) |

| Tension Accuracy | ±1% of set value (closed-loop control via tension sensor) |

| Wire Adaptation - Round | Diameter: 0.1 mm - 10 mm (enameled copper/aluminum wire, insulated wire) |

| Wire Adaptation - Flat | Cross-section: 1 mm×3 mm - 5 mm×15 mm (small flat insulated wire) |

| Pay-Off Speed | 0.2 m/min - 5 m/min (stepless speed regulation, synced with winding machines) |

| Speed Stability | ±0.2 m/min |

Advantages

1. Precise micro-tension control for small-section conductors:For fine-gauge conductors commonly used in low-voltage applications (0.1-10mm diameter enameled and insulated wires), the tension control range is precise, ranging from 5-500N (adjustable in 1N increments) with an accuracy of ±1%. This prevents excessive tension from thinning the conductor and damaging the insulation (e.g., paint peeling off the enameled wire), or insufficient tension from causing loose windings and excessive gaps (impacting electrical performance and heat dissipation). This perfectly meets the demand for gentle handling of fine conductors in low-voltage windings.

2. Flexible adaptability for multiple scenarios and strong compatibility:Compatible with a variety of conductor types (round enameled wire, flat insulated wire, and thin wire bundles), eliminating the need for frequent replacement of core components; only adjustments to the guide pulley and tension parameters are required.

Compatible with diverse products such as low-voltage transformer coils, motor stator/rotor windings, and micro-coils for home appliances (e.g., air conditioners and washing machines). Over 50 pre-set process parameters (e.g., tension and speed for different conductor types) are supported, eliminating the need for repeated adjustments when switching between conductor types, improving multi-batch production efficiency.

3. Good automation linkage reduces labor costs:It supports PLC linkage (e.g., RS485 communication) with low-voltage winding machines and wire cutting machines, automatically synchronizing the payout speed (steplessly adjustable from 0.2-5m/min) with the winding rhythm, eliminating manual adjustments that can cause wire accumulation or wire breakage due to excessively fast payouts. Some models are equipped with a wireless remote control, eliminating the need for workers to operate the machine from close proximity, reducing workshop movement and improving production safety.

4. Comprehensive safety measures reduce scrap rates:Built-in abnormal tension alarms (automatic shutdown within ±3% of tolerance), wire break detection, and wire jam protection prevent faults immediately, preventing unqualified windings from entering subsequent processes. (For example, continued winding of damaged wires can cause short circuits in the finished product.) The guide wheels are made of wear-resistant polyurethane, leaving thin wires scratch-free, further reducing the risk of scrap due to equipment wear.

5. Compact and easy to deploy, adapting to workshop space:Compared to high-voltage tension pay-off stands, these are more compact (mostly vertical, occupying ≤1.5 m2) and lighter (approximately 300-800 kg). They require no dedicated heavy foundation and can be flexibly deployed anywhere on the low-voltage electrical production line. With an operating noise level of ≤60 dB, they will not interfere with other precision equipment in the workshop, meeting the environmental requirements of precision low-voltage electrical production.

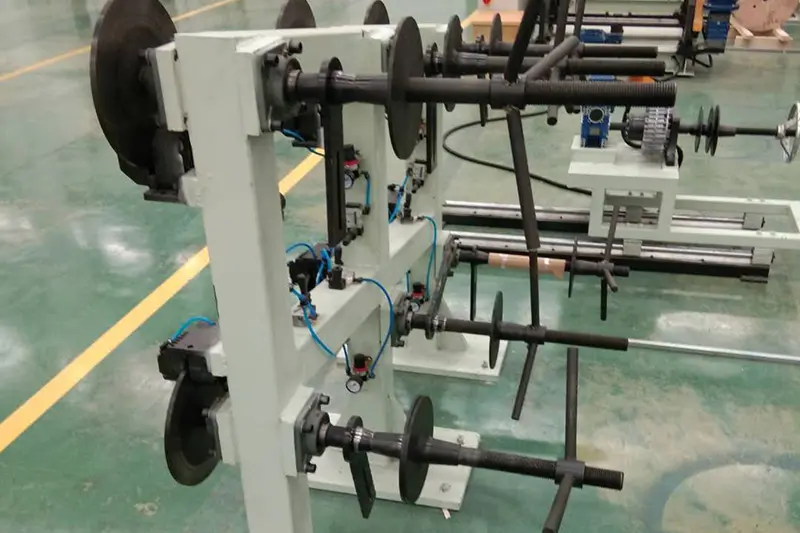

Product Display

Application

I. Low-Voltage Distribution Transformers (Main Scenario)

For 10kV/0.4kV distribution transformers, it controls 5-300N tension for 0.5-5mm wires to keep coils tight (avoids heat loss/looseness). It syncs with layer winding machines to ensure even wire arrangement, preventing turn-to-turn breakdown.

II. Low-Voltage Control Transformers

For industrial control transformers (e.g., 220V/36V), it uses 5-50N low tension to protect thin wires (0.1-1mm) from breaking or enamel damage. It maintains stable speed to reduce turn count errors (≤±1 turn).

III. Low-Voltage Isolation Transformers

For transformers requiring high insulation (e.g., medical/PV use), its polyurethane guide wheels and ±1% tension accuracy protect thin insulation layers. It balances tension for 2-4 parallel wires to ensure even coil resistance.

IV. Dry-Type Low-Voltage Transformers (Epoxy-Cast)

For SCB-series dry transformers, it ensures wire spacing error ≤0.1mm (avoids casting bubbles). It stores process parameters for mass production, guaranteeing coil consistency without repeated debugging.