High-Quality Custom Manual Hand Winding Machines from Trusted Factory Suppliers

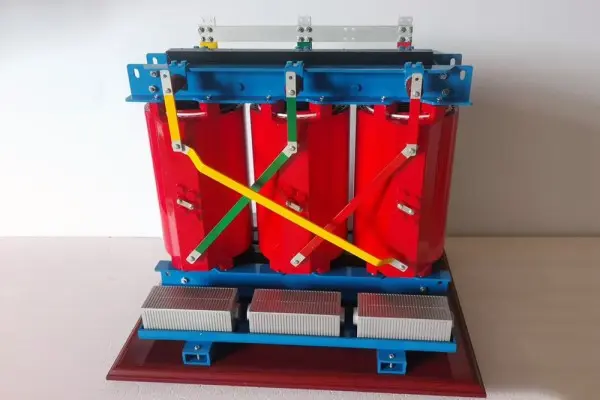

In need of a dependable manual hand winding machine? Our machines are crafted for both efficiency and durability, suitable for a variety of manufacturing processes. As a committed manufacturer, we focus on precision and quality in every unit produced. By partnering with us, you benefit from wholesale pricing, allowing you to stick to your budget while still receiving exceptional machinery. We are dedicated to providing excellent service, with a knowledgeable team ready to assist you with inquiries or maintenance advice. Based in WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we aim to enhance your business operations and improve your production line with our manual hand winding machines.

10 Essential Tips For Manual Hand Winding Machine From Concept to Delivery Pioneers in the Field

When it comes to manual hand winding machines, understanding the nuances from concept to delivery is crucial for buyers in the machinery sector. The first essential tip is to prioritize technological innovation, as this significantly impacts efficiency and output quality. Identify machines that incorporate advanced features such as adjustable tension control and user-friendly interfaces, ensuring seamless operation and reduced training time for staff. Additionally, consider the machine's compatibility with various materials, as this versatility can enhance your production capabilities.

Quality service is another key factor to consider. A reliable supplier should offer comprehensive support, including installation, troubleshooting, and maintenance. Effective communication during the procurement process can ensure that the machine meets your specific requirements while minimizing downtime. Furthermore, it's essential to evaluate the supplier's commitment to long-term partnerships, which can lead to better pricing and access to future innovations.

Lastly, sustainability should not be overlooked. As the industry shifts towards more eco-friendly practices, selecting a machine designed with energy efficiency in mind can lower operating costs and contribute to your company's sustainability goals. By focusing on innovative technology, exceptional service, and environmentally friendly options, you can ensure that your investment in a manual hand winding machine will pay off in the long run, enhancing productivity and supporting your business growth.

10 Essential Tips For Manual Hand Winding Machine From Concept to Delivery Pioneers in the Field

| Tip No. | Tip Description | Expected Outcome | Implementation Time (Days) |

|---|---|---|---|

| 1 | Use precise measurements for the winding process to ensure consistency. | Improved accuracy and reduced material waste. | 2 |

| 2 | Regularly calibrate the machine for optimal performance. | Enhanced productivity and lower defect rates. | 1 |

| 3 | Train operators thoroughly in winding techniques. | Reduced errors and improved quality of output. | 5 |

| 4 | Implement a consistent maintenance schedule. | Prolonged machine life and reduced downtime. | 3 |

| 5 | Utilize quality materials for winding to enhance durability. | Improved product quality and customer satisfaction. | 7 |

| 6 | Streamline the workflow to reduce unnecessary steps. | Increased efficiency and faster delivery times. | 4 |

| 7 | Implement feedback systems for continuous improvement. | Higher quality outcomes based on user input. | 5 |

| 8 | Monitor and analyze production metrics regularly. | Data-driven decisions lead to better processes. | 3 |

| 9 | Stay updated with industry trends and advancements. | Innovation in processes and products. | Continuous |

| 10 | Establish strong supplier relationships for reliable delivery. | Consistent supply chain stability and reduced delays. | Ongoing |

7 Key Tips To Manual Hand Winding Machine Manufacturer Service Backed by Expertise

D

Daniel Lopez

The quality of the items is very high. Their after-sales service team was not only friendly but also professional, ensuring all my needs were met.

14

August

2025

A

Addison Gray

Great quality product! The after-sales personnel were knowledgeable and reflected a very professional demeanor.

27

August

2025

S

Scarlett Scott

Top quality! I truly appreciated the professional and friendly assistance from the after-sales service team.

11

August

2025

A

Aiden Hall

Outstanding quality! The post-purchase support provided was remarkably professional and efficient.

28

August

2025

J

Jacob Rivera

Very satisfied with this purchase! The quality is impressive, and the customer support was remarkably professional.

29

September

2025

E

Evelyn Collins

Excellent purchase! The product quality is outstanding, and the after-sales team handled my inquiries with great professionalism.

22

August

2025