Wholesale Transformer Manufacturing Process: Factories and Top Manufacturers

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we specialize in the manufacturing of transformers, ensuring top-notch quality and compliance with international standards. Our advanced production facilities in China enable us to implement cutting-edge techniques that guarantee the durability and performance of each product. We prioritize customer service and collaborate closely with clients to customize our transformers according to their unique requirements. Our flexible manufacturing process not only meets industry demands but also supports scalability for businesses of all sizes. Rely on us for innovative solutions that enhance your operations, backed by a manufacturer dedicated to excellence in both product quality and service.

Step-by-Step Guide Manufacturing Process Of Transformer More Than a Supplier - A Partner Ahead of the Curve

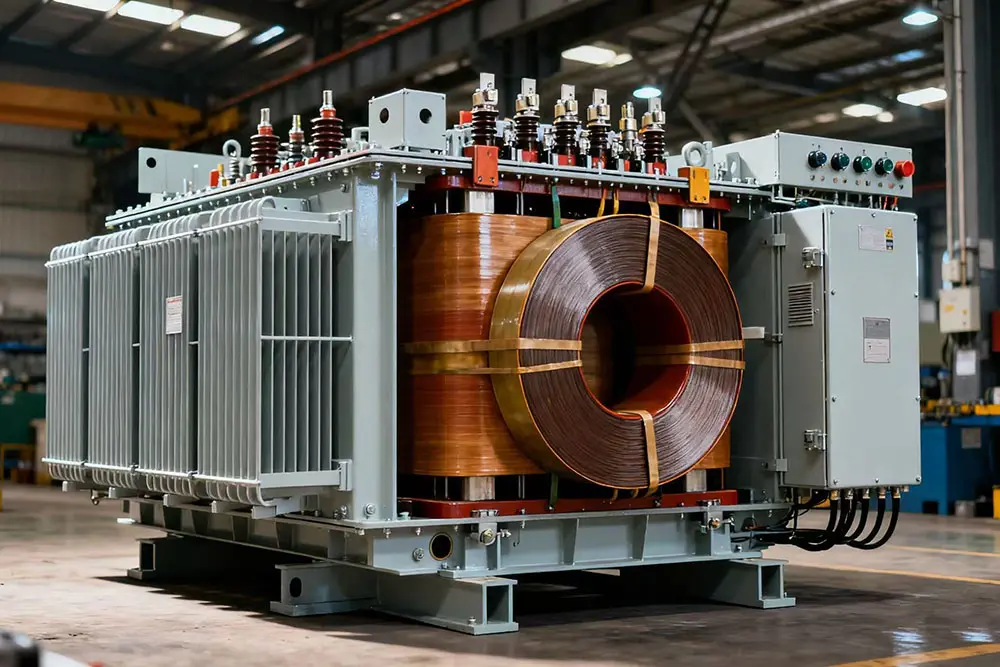

In today's rapidly evolving energy landscape, understanding the manufacturing process of transformers is essential for global purchasers seeking reliable partnerships. A step-by-step guide not only sheds light on the intricacies of production but also emphasizes the importance of choosing a supplier that acts as a strategic partner. The journey begins with the careful selection of raw materials, where quality is paramount in ensuring efficiency and longevity. Following this, precise engineering and advanced manufacturing techniques transform these materials into high-performance components, incorporating cutting-edge technology that enhances operational capabilities.

Once constituent parts are crafted, rigorous testing protocols come into play, validating the durability and functionality of each transformer. This phase is crucial; it ensures that the end product meets international standards and customer expectations. Beyond production, a true partnership extends to after-sales support and continuous innovation, where feedback loops facilitate improvements and adaptations to shifting market demands. By aligning with manufacturers that prioritize not just product delivery but also collaborative growth, purchasers can navigate the complexities of the energy sector with confidence and foresight, positioning themselves ahead of the curve in an ever-competitive environment.

Step-by-Step Guide Manufacturing Process Of Transformer More Than a Supplier - A Partner Ahead of the Curve

| Process Step | Description | Materials Used | Duration (Days) | Quality Standards |

|---|---|---|---|---|

| Design and Engineering | Initial design and engineering calculations to meet specifications. | Steel, Copper, Insulation Materials | 10 | ISO 9001 |

| Core Laminating | Cutting and stacking of laminated steel sheets to form the core. | Laminated Steel Sheets | 5 | IEEE 1547 |

| Winding | Coiling of copper wire around the core to form the primary and secondary windings. | Copper Wire, Insulation | 8 | ANSI C57.12.00 |

| Assembly | Assembling all components including bushings, tank, and cooling systems. | Steel Tank, Cooling Oil | 7 | IEC 60076 |

| Testing | Conducting various tests to ensure functionality and safety. | Testing Equipment | 3 | UL 508 |

| Final Inspection | Final quality checks before shipment. | Inspection Tools | 2 | ISO 14001 |

Ultimate Guide To Manufacturing Process Of Transformer Winning in 2025 Now Trending

E

Ella Allen

I’m thrilled with my purchase! Impressive quality and the support staff displayed exceptional professionalism throughout.

04

August

2025

S

Sofia Nelson

Excellent product! I was particularly impressed with the professionalism and responsiveness of their customer service team.

17

September

2025

S

Sebastian Bell

Incredible quality! The customer support staff were not only professional but also went out of their way to assist me.

17

September

2025

A

Addison Gray

Great quality product! The after-sales personnel were knowledgeable and reflected a very professional demeanor.

27

August

2025

D

David Green

I have no complaints about the quality. The support team was very helpful and displayed remarkable professionalism.

05

August

2025

E

Emily Walker

This product stands out in terms of quality! The post-purchase service was equally impressive with knowledgeable representatives.

06

September

2025