Custom Motor Winding Copper - Reliable Manufacturer & Supplier for Quality Solutions

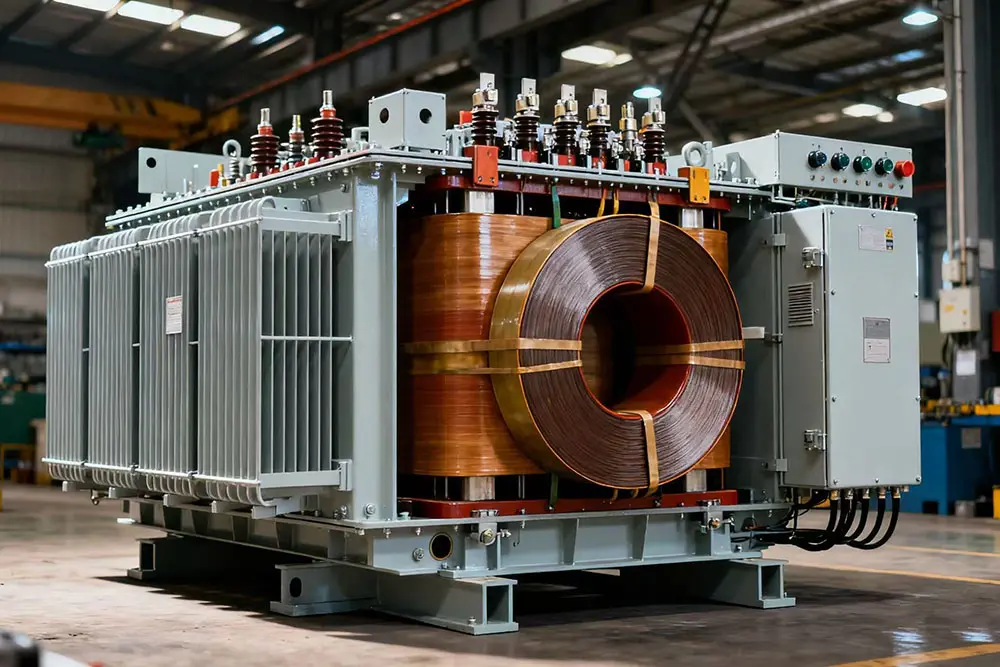

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we are a reputable supplier specializing in high-quality Motor Winding Copper sourced directly from leading manufacturers in China. Our products meet rigorous industry standards, ensuring exceptional durability and conductivity suitable for various applications. We prioritize the needs of B2B purchasers, delivering exceptional value through our collaborations with reliable manufacturers. Count on us for prompt service and timely delivery of superior materials that enhance your production efficiency. Partner with us to benefit from our expertise and commitment to quality in all your motor winding copper requirements. Contact us today to support your manufacturing objectives!Step-by-Step Guide To Motor Winding Copper Your Trusted OEM Partner Manufacturer

In the ever-evolving machinery industry, the importance of high-quality motor winding copper cannot be overstated. As global demand for efficient and sustainable energy solutions grows, businesses are seeking partners who can deliver reliable and advanced manufacturing solutions. This step-by-step guide will walk you through the essential aspects of sourcing motor winding copper, ensuring you find a trusted OEM partner to meet your production needs.

First, it is crucial to understand the specifications required for your motor winding applications. Quality motor winding copper is characterized by its electrical conductivity, thermal resistance, and durability. When evaluating potential suppliers, ensure they adhere to international standards and certifications, which guarantee the copper's performance under various operational conditions. Look for partners who not only provide raw materials but also offer expert guidance in the selection process, helping you optimize your production efficiency.

Beyond product quality, consider the manufacturer's commitment to technological innovation. A partner that invests in research and development is more likely to offer cutting-edge solutions and enhancements, ultimately benefiting your manufacturing capabilities. Collaborating with a manufacturer that aligns with your vision for sustainability and efficiency will empower your business as it adapts to the dynamic energy landscape. With the right partnership, you can ensure that your motor winding copper needs are not only met but exceeded, paving the way for future growth and success.

Step-by-Step Guide To Motor Winding Copper Your Trusted OEM Partner Manufacturer

| Step | Process Description | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Prepare the copper wire and tools. | Wire cutters, measuring tape. | 30 minutes |

| 2 | Create the winding pattern on the stator. | Template, pencil. | 1 hour |

| 3 | Wind the copper wire according to the design. | Winding machine. | 2 hours |

| 4 | Secure the windings with insulation. | Insulation tape. | 30 minutes |

| 5 | Test the windings for continuity. | Multimeter. | 15 minutes |

Don't Miss These Motor Winding Copper Factory Winning in 2025

W

William Green

I received a fantastic product. The customer service was very responsive and the team demonstrated a high level of professionalism.

01

September

2025

D

David Green

I have no complaints about the quality. The support team was very helpful and displayed remarkable professionalism.

05

August

2025

A

Anthony Clark

A fantastic product! The build quality is very impressive, and follow-up service from the team was prompt and professional.

21

August

2025

D

Daniel Young

The quality of this item is top-tier. The customer service team demonstrated great professionalism in addressing my queries.

18

August

2025

S

Sofia King

This item is simply fantastic! Quality is unbeatable, and the support was incredibly helpful and professional.

16

August

2025

E

Emily Johnson

The product exceeded my expectations in both performance and quality. The customer service team was highly professional and responsive to my inquiries.

18

September

2025