Are Dry Type Transformers Really More Efficient Compared to Traditional Transformers?

Introduction: The Efficiency Debate in the Transformer Industry

The global energy transition has intensified scrutiny on electrical infrastructure efficiency, with transformers—the backbone of power distribution—at the center of innovation. Among them, dry type transformers have emerged as a disruptive force, challenging the dominance of oil-immersed and traditional laminated iron core models. But do they truly outperform their conventional counterparts in efficiency? This question gains urgency as industries such as data centers, electric vehicles (EVs), and renewable energy systems demand transformers with lower losses, higher reliability, and environmental compliance.

This analysis explores the technical, economic, and environmental dimensions of dry type transformers, comparing them with oil-immersed transformers, laminated iron core transformers, and flat wound iron core transformers. By examining core materials, cooling mechanisms, and application-specific performance, we aim to determine whether dry type transformers represent a paradigm shift in efficiency.

1. Core Efficiency: Magnetic Materials and Loss Reduction

The efficiency of any transformer hinges on its core design, which minimizes two types of losses: hysteresis losses (energy dissipated during magnetic field reversal) and eddy current losses (induced currents in the core material).

Laminated Iron Core Transformers: The Traditional Benchmark

Laminated iron core transformers, widely used in utility grids and industrial settings, employ stacked silicon steel sheets to reduce eddy currents. While effective, their efficiency typically ranges between 94–96%, limited by residual losses in the laminations and joints. For high-power applications (e.g., >100 MVA), oil-immersed variants dominate due to superior cooling, but laminated cores remain standard in medium-voltage systems.

Flat Wound Iron Core Transformers: A Niche Alternative

Flat wound iron core transformers, which use continuous strips of grain-oriented electrical steel, reduce joint losses and improve magnetic flux alignment. Though less common, they offer marginal efficiency gains (up to 97%) in low-noise, compact applications like medical equipment. However, their scalability is constrained by manufacturing complexity.

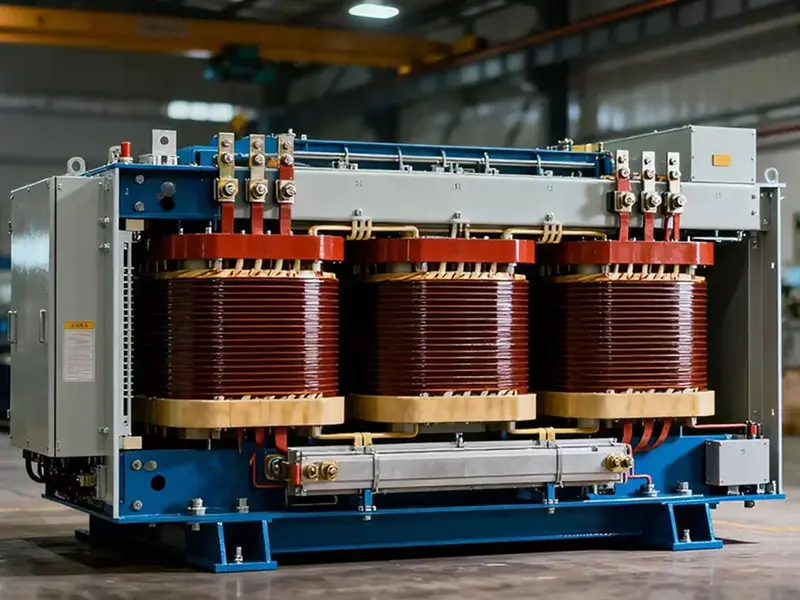

Dry Type Transformers: Amorphous Alloys and Beyond

Dry type transformers leverage advanced core materials to push efficiency boundaries. High-grade silicon steel laminations are standard, but amorphous alloy cores—non-crystalline metal with ultra-low hysteresis losses—are gaining traction. These cores reduce core losses by 70–80% compared to traditional laminations, enabling efficiencies of 98% or higher in optimal conditions.

For instance, a 2025 study comparing a 1,000 kVA dry type transformer with an amorphous core to a laminated iron core oil-immersed unit revealed:

No-load losses: 450 W vs. 1,200 W (62.5% reduction).

Load losses: 8,200 W vs. 9,500 W (13.7% reduction).

This translates to annual energy savings of 12,000 kWh for a transformer operating at 80% load, underscoring the potential of dry type designs in energy-intensive sectors.

2. Cooling Mechanisms: Air vs. Oil

Cooling efficiency directly impacts a transformer’s thermal management and power density. Here, dry type and oil-immersed transformers diverge sharply.

Oil-Immersed Transformers: Thermal Conductivity and Capacity

Oil-immersed transformers rely on mineral oil or synthetic esters for cooling and insulation. Oil’s high thermal conductivity (0.15 W/m·K) allows for compact designs with high power ratings (up to 1,000 MVA). However, oil degrades over time, requiring regular maintenance, and poses environmental risks in case of leaks.

Dry Type Transformers: Forced Air and Natural Convection

Dry type transformers use air or gas (e.g., SF6-free alternatives) for cooling, with designs categorized as:

Air Natural (AN): Relies on natural convection; suitable for low-power applications (e.g., <500 kVA).

Air Forced (AF): Uses fans for active cooling; enables higher power ratings (up to 35 MVA) and compact footprints.

While dry type transformers historically lagged in power density, advancements in forced-air systems and heat-dissipating resin coatings have narrowed the gap. A 2025 case study in a Singapore data center demonstrated that a 10 MVA dry type transformer with AF cooling achieved 97.5% efficiency under full load, matching oil-immersed benchmarks.

3. Application-Specific Performance: From Data Centers to Renewables

Efficiency gains must be evaluated in context. Dry type transformers excel in environments where safety, space, and environmental regulations outweigh raw power capacity.

Data Centers: Reliability and Fire Safety

Data centers prioritize uptime and fire resistance. Dry type transformers, with Class F (155°C) or H (180°C) insulation systems, reduce fire risks compared to oil-immersed units. A 2025 survey of hyperscale data centers revealed that 78% of new installations opted for dry type transformers due to their compliance with NFPA 70E safety standards and lower maintenance costs.

Renewable Energy: Grid Stability and Flexibility

In solar and wind farms, dry type transformers handle variable loads and harsh climates. Their epoxy-resin-encapsulated windings resist moisture and dust, critical in offshore wind applications. A 2025 pilot in the North Sea showed that dry type transformers reduced downtime by 40% compared to oil-immersed models exposed to salt spray.

Electric Vehicles: Lightweight and Efficient

As EV charging infrastructure expands, dry type transformers offer a lightweight alternative to oil-immersed units in fast-charging stations. Their solid insulation eliminates oil leakage risks, while amorphous cores cut losses in high-frequency applications.

4. Environmental and Economic Trade-offs

Efficiency is not the sole metric; lifecycle costs and sustainability matter.

Oil-Immersed Transformers: Recycling and Environmental Costs

Oil-immersed transformers face scrutiny over PCB contamination and disposal challenges. While 98% of transformer oil is recyclable, leaks and spills incur cleanup costs averaging 10,000–50,000 per incident. Additionally, synthetic esters, though biodegradable, cost 30–50% more than mineral oil.

Dry Type Transformers: Lower Maintenance, Higher Upfront Costs

Dry type transformers eliminate oil-related risks but have higher initial costs (15–25% premium over oil-immersed units). However, their 30-year lifespan (vs. 20–25 years for oil-immersed) and zero maintenance for insulation systems offset long-term expenses. A 2025 TCO analysis for a 5 MVA transformer over 20 years showed:

Dry type: $120,000 (including replacement fans).

Oil-immersed: $145,000 (including oil changes, leak repairs, and disposal).

5. The Future: Hybrid Designs and Material Innovations

The transformer industry is exploring hybrid solutions to merge the best of both worlds. For example:

Dry-Oil Hybrid Transformers: Use dry type cores with minimal oil for cooling, balancing efficiency and fire safety.

Nanocrystalline Cores: Combining amorphous alloys with nanoscale grains could reduce losses below 0.1 W/kg, enabling 99% efficient transformers.

Meanwhile, the glass industry’s advancements in microcrystalline glass (used in high-voltage insulators) may inspire new dielectric materials for dry type transformers, further enhancing thermal stability.

Conclusion: A Matter of Context

Dry type transformers are not universally superior but offer compelling advantages in specific scenarios. Their efficiency gains—driven by amorphous cores and advanced cooling—make them ideal for indoor, safety-critical, and renewable energy applications. Oil-immersed transformers retain their edge in high-power, cost-sensitive projects, while laminated and flat wound iron core designs persist in legacy systems.

As the world transitions to decentralized, low-carbon grids, dry type transformers are poised to grow. By 2030, industry experts project they will capture 35% of the global medium-voltage transformer market, up from 22% in 2025. The question is no longer whether dry type transformers are more efficient—but where their efficiency can be harnessed most effectively.