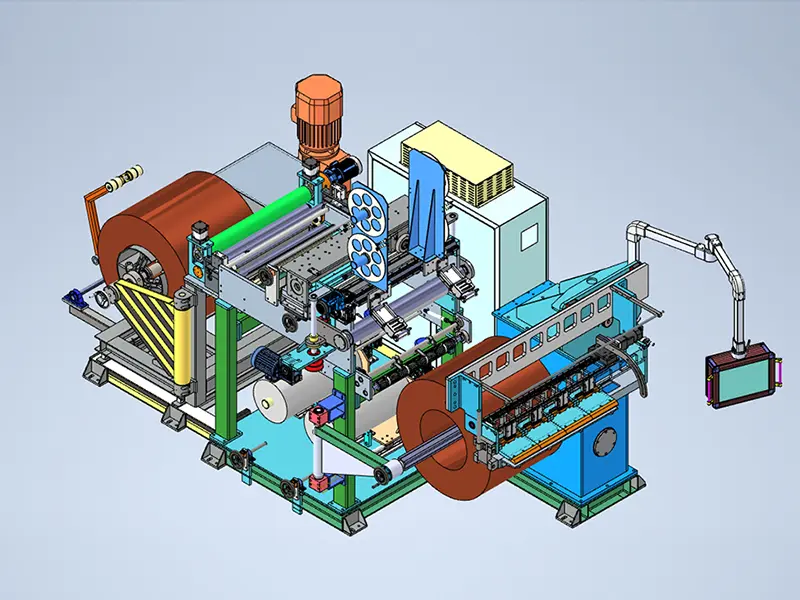

BRJ-1600-II Foil Winding Machine Launched, Leading the Upgrade of Intelligent Transformer Manufacturing

Recently, Wuxi Shuhong Machinery Technology Co., Ltd. officially released its new generation BRJ-1600-II multi-layer foil winding machine, marking a new level in the company's technological research and development and innovation capabilities in the field of transformer manufacturing equipment. With several innovative technologies and excellent performance parameters, this equipment will provide the transformer industry with a more efficient and intelligent coil manufacturing solution.

Technological Breakthroughs: Precise Tension Control and Intelligent Correction System

The BRJ-1600-II foil winding machine has achieved significant breakthroughs in core technologies. The equipment adopts an advanced hydraulic tension control system, which can achieve continuously adjustable constant tension output in the range of 0-18000N, with tension fluctuation controlled within ±3%, far superior to the industry average. This technological breakthrough ensures the stability of material tension during the coil winding process, significantly improving product quality and consistency.

The intelligent correction system is another major highlight of the equipment. Through multi-sensor fusion technology and servo linear motor drive, the system achieves high-precision correction of ±0.5mm, with a response time of less than 50 milliseconds. This technological innovation effectively solves the common problem of uneven edges in traditional equipment, greatly improving the neatness and electrical performance of the coil.

Welding Process Innovation: High-Precision Automated Welding System

The TIG AC/DC tungsten inert gas welding system equipped with the device represents the advanced level of welding technology in the industry. The system uses a precision transmission mechanism combining linear guides and ball screws, combined with servo motor drive, to achieve precise positioning of the welding head within a 1600mm range. The intelligent welding parameter adjustment function can automatically adjust process parameters according to the foil thickness, ensuring a welding surface fusion rate of over 95%.

It is particularly worth mentioning that the welding pressure plate adopts a partitioned control design, where the pressure in different areas can be adjusted independently. This innovative design effectively suppresses thermal deformation during the welding process, reducing the flatness error after welding by 60%. This technological breakthrough is of great significance for improving the reliability and service life of transformers.

Intelligence and Digitalization: Future-Oriented Manufacturing Solutions

The BRJ-1600-II is equipped with a 10.4-inch touch screen operation interface and a Siemens PLC control system, supporting the storage and retrieval of 100 process recipes. The equipment features comprehensive digital interfaces, enabling seamless integration with factory MES systems via the OPC UA protocol for real-time production data acquisition and analysis. This functionality not only enhances the precision of production management but also provides strong support for process optimization and quality traceability.

The equipment also boasts predictive maintenance capabilities. Through real-time monitoring and data analysis of key component operating status, the system can provide early warnings of potential failures, shifting from scheduled maintenance to on-demand maintenance. This innovative feature will significantly improve equipment utilization and operational reliability, reducing maintenance costs for users.

Market Application and Customer Value

According to the company's technical director, the BRJ-1600-II was designed with the diverse and personalized needs of different users in mind. The equipment supports modular configuration, allowing for flexible combinations based on specific user requirements. The quick-change system for winding shafts enables switching between different specifications within 30 minutes, and the pressure roller length can be adjusted within the range of 288-1198mm, accommodating the manufacturing needs of various coil specifications.

In practical applications, the equipment has demonstrated significant technical advantages. Test data shows that coils manufactured using the BRJ-1600-II can reduce transformer no-load losses by 15-20%, shorten production cycles by 35%, and maintain a product pass rate of over 99.5%. These performance indicators fully demonstrate the equipment's exceptional capabilities in improving production efficiency and quality control.

R&D Strength and Quality Control

As a national high-tech enterprise, Wuxi Shuhong Machinery has been deeply involved in the foil winding machine field for over ten years, establishing a comprehensive R&D system and quality management system. The company has a professional R&D team and advanced production equipment, and all key components are selected from internationally renowned brands, ensuring the reliability and stability of the equipment.

The company representative stated: "The launch of the BRJ-1600-II is a testament to our continuous technological innovation and customer-oriented R&D philosophy. We will continue to increase R&D investment and continuously optimize product performance to provide transformer manufacturing companies with higher-quality and more efficient equipment solutions."

Future Outlook

With the deepening of the global energy transition and the accelerated development of smart grids, the transformer industry is facing new development opportunities. Shuhong Machinery will continue to focus on the innovation and upgrading of foil winding machine technology, driving the equipment towards higher levels of automation and intelligence. The company plans to further increase its R&D investment over the next three years, establish an intelligent equipment R&D center, and build a complete solution capability ranging from equipment manufacturing to process optimization.

Industry experts believe that the launch of the BRJ-1600-II will further promote the upgrading of my country's transformer manufacturing technology and enhance the overall competitiveness of my country's power equipment manufacturing industry. As more and more transformer manufacturers adopt advanced production equipment, my country's power equipment industry will usher in a new round of development opportunities.