Can High-Speed, Precise Automatic Coil Winding Machines Revolutionize Industry Speed?

The world of manufacturing is changing fast. Everyone's chasing better speed, precision, and the ability to scale up. And right in the middle of this shift is the automatic coil winding machine—a game-changer for making coils used in electric motors, transformers, and all sorts of essential electronics.

The market for these machines is expected to grow steadily, at around 9.7% each year from 2025 to 2032. That’s serious expansion. But it makes you wonder: can these machines really keep up with what industries need today? Are they fast, accurate, and flexible enough?

In the following section, we will examine, together with Wuxi Shuhong Machinery Technology Co., Ltd., the trends, challenges, and innovations influencing the future of automatic winding technology.

The Rise of Automation: Why Speed and Precision Matter

Traditional coil winding processes, whether manual or semi-automated, have long been bottlenecks in production lines. Manual winding, while flexible, is labor-intensive, time-consuming, and prone to human error. Semi-automated systems, though faster, often lack the consistency needed for high-volume manufacturing. Enter the automatic winding machine—a fully computerized system designed to handle complex winding patterns with unparalleled speed and precision.

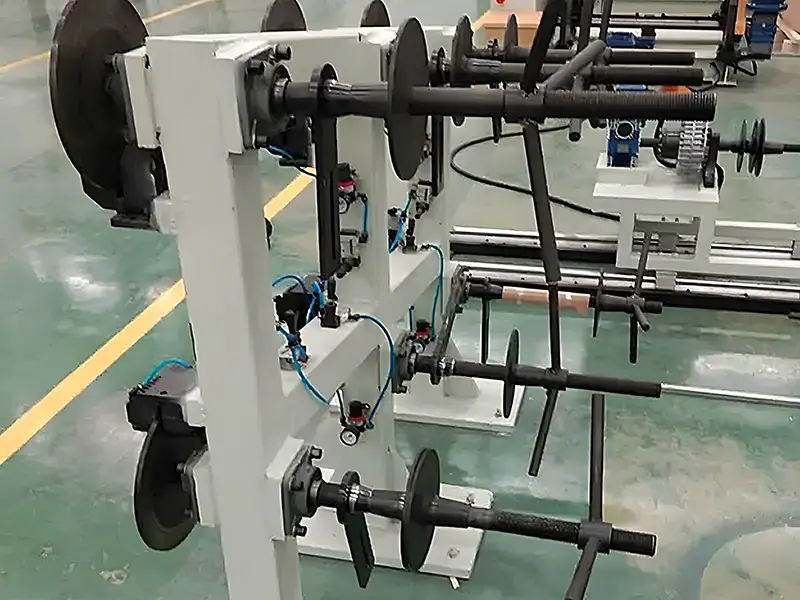

These machines are engineered to minimize human intervention, automating tasks such as wire tensioning, cutting, and coil ejection. By leveraging advanced sensors, servo motors, and programmable logic controllers (PLCs), they ensure each coil meets exact specifications, reducing waste and rework. For instance, a modern automatic winding machine can produce coils with a diameter ranging from 12 mm to 150 mm and lengths up to 110 mm, all while maintaining a tolerance of less than 0.1 mm. This level of precision is critical in industries like automotive electronics, where even minor deviations can lead to motor inefficiencies or failures.

Moreover, automation slashes production time. A single machine can wind hundreds of coils per hour, compared to just a few dozen by manual methods. This efficiency boost is particularly vital in sectors like renewable energy, where the demand for high-performance coils in wind turbines and solar inverters is soaring.

Beyond Speed: The Versatility of Toroidal Winding Machines

While general-purpose automatic winding machines dominate the market, niche applications demand specialized solutions. One such innovation is the toroidal winding machine, designed exclusively for winding coils around toroidal (doughnut-shaped) cores. These machines are indispensable in manufacturing toroidal inductors, current sensors, and power transformers, where uniform winding is essential for optimal magnetic field distribution.

Toroidal winding machines eliminate the kinks and overlaps common in manual winding, ensuring each turn is neatly aligned. This precision enhances the electrical properties of the coil, reducing energy losses and improving overall system efficiency. For example, toroidal inductors wound by automated systems exhibit up to 15% lower core losses compared to manually wound counterparts, making them ideal for high-frequency applications like switching power supplies and electric vehicle (EV) chargers.

The versatility of toroidal winding machines extends beyond traditional electrical components. They are also used in advanced medical devices, aerospace systems, and telecommunications equipment, where compact, high-performance coils are non-negotiable. As industries continue to miniaturize and optimize their products, the demand for these specialized machines will only grow.

Rewinding Machines: The Unsung Heroes of Sustainability

While new coil production dominates headlines, the rewinding machines segment is quietly revolutionizing sustainability in manufacturing. These machines are designed to refurbish used coils, extending their lifespan and reducing electronic waste. By carefully unwinding damaged or worn-out coils, cleaning the cores, and rewinding them with fresh wire, rewinding machines offer a cost-effective alternative to buying new components.

This process is particularly valuable in industries like industrial automation and HVAC, where motors and transformers are expensive to replace. A well-maintained rewound coil can retain 95% or more of its original efficiency, making it a viable option for businesses looking to cut costs and reduce their carbon footprint. Moreover, rewinding machines are equipped with diagnostic tools to assess the health of a coil before refurbishment, ensuring only viable components are processed.

The sustainability angle is gaining traction globally. With regulations tightening on electronic waste disposal and corporate sustainability goals becoming mandatory, rewinding machines are positioned as eco-friendly solutions that align with circular economy principles.

Challenges and Innovations: Navigating the Road Ahead

Despite their advantages, automatic winding machines face several challenges. The initial cost of investment remains a barrier for small and medium-sized enterprises (SMEs), though leasing models and government subsidies are making the technology more accessible. Additionally, the complexity of these machines requires skilled technicians for setup, maintenance, and troubleshooting—a talent gap that the industry is actively addressing through training programs and user-friendly interfaces.

On the innovation front, manufacturers are integrating artificial intelligence (AI) and machine learning (ML) to enhance machine capabilities. AI-driven systems can predict maintenance needs, optimize winding parameters in real time, and even self-correct errors during production. For example, a machine equipped with ML algorithms can analyze thousands of winding patterns to identify the most efficient sequence for a given coil, reducing material usage and cycle times.

Another trend is the rise of modular winding machines, which allow manufacturers to swap out components to handle different coil types or sizes. This flexibility is crucial in industries like consumer electronics, where product lifecycles are short and design changes frequent. A modular machine can be reconfigured in minutes, ensuring minimal downtime and maximum productivity.

The Future of Winding: A Global Perspective

The global market for automatic coil winding machines is driven by regional dynamics. Asia-Pacific, home to major electronics and automotive manufacturing hubs like China, Japan, and South Korea, dominates the market, accounting for over 45% of global revenue. Europe and North America follow, with strong demand from renewable energy and aerospace sectors.

Looking ahead, the EV revolution will be a key growth driver. An EV motor requires up to 10 times more coils than a traditional internal combustion engine (ICE) vehicle, creating a massive demand for high-speed, automated winding systems. Similarly, the expansion of 5G networks and data centers will fuel demand for precision coils in telecommunications equipment.

As industries continue to prioritize efficiency, sustainability, and miniaturization, the role of automatic winding machines will only expand. Whether it’s a general-purpose machine churning out coils for household appliances or a specialized toroidal winder crafting components for medical scanners, these machines are the unsung heroes of modern manufacturing.

Conclusion: A Winding Road to the Future

The automatic coil winding machine is not just a tool—it’s a catalyst for industrial transformation. By combining speed, precision, and versatility, these machines are enabling industries to meet the demands of a fast-paced, technology-driven world. From toroidal winding machines ensuring optimal performance in critical applications to rewinding machines promoting sustainability, the ecosystem of winding technology is evolving to address tomorrow’s challenges today.

As the market continues to grow, manufacturers must invest in innovation, skill development, and sustainable practices to stay ahead. For businesses, embracing automation is no longer an option—it’s a necessity to remain competitive in a global landscape where efficiency and quality reign supreme. The question is not whether automatic winding machines can usher in a new speed for the industry, but how quickly we can adapt to harness their full potential. The answer, it seems, is already winding its way into the future.