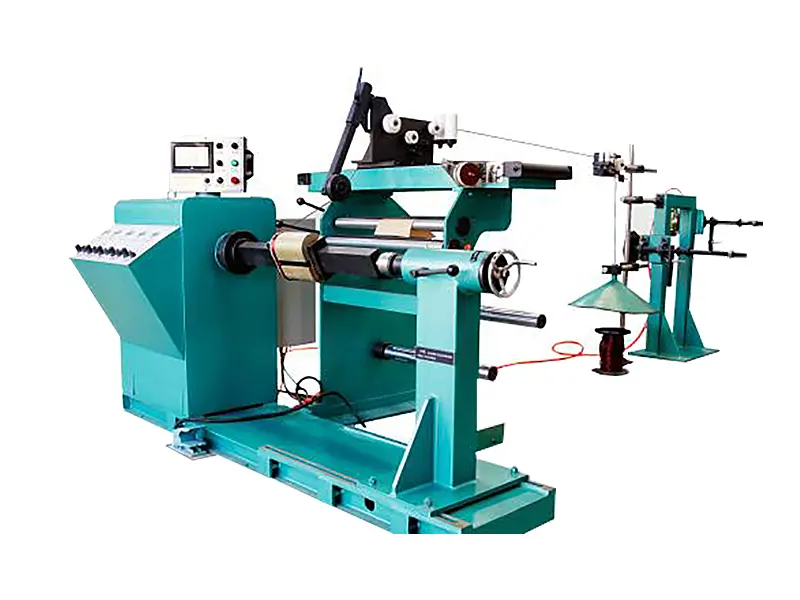

GZR-800 (2+1): High-Precision Auto Winder Leading Transformer Tech Upgrade

Driven by the global energy transition and the intelligent construction of power grids, the power equipment manufacturing industry is undergoing profound technological innovation. As a core component of transformers, the manufacturing quality of coils directly affects the performance and energy efficiency of the entire machine. In recent years, with the mature application of industrial automation technology, automatic high-voltage coil winding machines have become key equipment for improving the manufacturing level of transformers. Among them, the GZR-800 (2+1) high-voltage coil automatic winding machine, with its innovative technical design and excellent process performance, is redefining industry production standards.

Automatic Winding Machine: A Core Breakthrough in Precision Manufacturing

Modern coil winding processes demand increasingly higher levels of precision, efficiency, and consistency. Traditional coil winding methods rely on manual operation, which suffers from inherent limitations such as low production efficiency, poor quality stability, and high labor intensity. The emergence of automatic winding machines has completely changed this situation. This equipment integrates precision mechanical transmission, servo control systems, and intelligent sensing technology to achieve fully automated control of the entire process, from wire feeding and arrangement to winding.

The GZR-800 (2+1) automatic winding machine represents the technological forefront in this field. The device adopts a modular design and is equipped with high-performance servo motors and a PLC control system, enabling automatic wire arrangement with a precision of 0.01mm. Its unique (2+1) design concept supports flexible switching between parallel winding of double round wires and single flat wire winding, greatly improving the equipment's process adaptability. In the production process of iron core transformers, this automatic winding machine ensures the axial tightness and interlayer uniformity of the coil winding, providing reliable assurance for improving the overall performance of the transformer.

Technological Innovation: Driving Manufacturing Upgrades

The technological innovation of this automatic winding machine is mainly reflected in several key aspects. First, the equipment uses a hard fabric gear mechanical transmission system, which effectively reduces operating noise while ensuring transmission accuracy. Second, the application of variable frequency speed control technology allows the equipment to achieve stepless speed regulation within the range of 0-220 r/min, and the winding process can be optimized by presetting the start and stop slopes. Thirdly, the equipment is equipped with a high-precision tension control system that can automatically adjust tension parameters according to wire diameter changes, ensuring the stability of wire tension during the winding process.

In terms of the control system, the equipment uses a five-digit display counter, supports multi-segment winding programming with up to 20 segments, and has a power-off memory function. These features enable the equipment to meet the winding requirements of complex coil structures. Especially in the production of wound core transformers, the equipment can precisely control the winding parameters of each layer of coils, ensuring a perfect fit between the core and the coils.

Application Value: Enhancing Industry Competitiveness

The widespread application of automatic winding machines is reshaping the competitive landscape of the transformer manufacturing industry. For manufacturing enterprises, the investment in the GZR-800 model equipment can bring about multi-faceted benefits. In terms of production efficiency, the automated winding speed can reach 3-5 times that of traditional manual operation, and it can achieve 24-hour continuous operation. In terms of quality control, the consistency and repeatability of the equipment are far superior to manual operation, significantly reducing the product defect rate.

More importantly, this automatic winding machine can significantly improve the technical content of the products. In emerging fields such as new energy power generation and electric vehicle charging facilities, the performance requirements for transformers are increasing. By using coils produced by high-precision automatic winding machines, it is possible to ensure that transformers have higher energy efficiency ratings and more stable operating performance. This gives manufacturing companies a significant advantage in competing in the high-end market.

Technical Configuration: Laying the Foundation for Excellent Performance

The excellent performance of the GZR-800 (2+1) automatic winding machine is due to its high-quality component configuration. The core control system of the equipment uses a servo system and PLC controller from Inovance Technology, ensuring precise and reliable motion control. Electrical components are selected from Schneider Electric products, the pneumatic system uses Airtac pneumatic components, and the linear guides are from TBI. The combination of these high-quality components provides a solid foundation for the long-term stable operation of the equipment.

The technical parameters of the equipment also reflect its powerful process capabilities. The maximum working torque reaches 200 N·m, and it can handle workpieces weighing no more than 500 kg, supporting coil winding with an outer diameter of no more than 600 mm and an axial height of no more than 750 mm. These specifications enable it to meet the production needs of most small and medium-sized transformers.

Industry Outlook: New Trends in Intelligent Manufacturing

With the in-depth development of Industry 4.0 technologies, coil winding equipment is evolving towards greater intelligence and networking. Future automatic winding machines will not only be independent processing equipment but will also become an important component of intelligent manufacturing systems. Through the application of Internet of Things (IoT) technology, equipment will be able to upload production data in real time, enabling remote monitoring and fault diagnosis. Combined with big data analysis, it will also be possible to optimize winding process parameters and further improve product quality.

Driven by the concept of sustainable development, energy conservation and environmental protection have also become important directions for the development of automatic winding machine technology. New equipment will focus more on energy efficiency, reducing energy consumption through optimized drive and control systems. At the same time, the maintainability and recyclability of the equipment will also receive more attention.