Has the EV Revolution Spurred Customization Demand in Coil Winding Equipment?

Introduction: The EV Revolution's Ripple Effect

The world’s shift to electric vehicles is one of the biggest tech changes of our time—and it’s sending ripples through tons of industries and how things are made. One area that’s really transforming? Coil winding equipment. That’s the machinery that makes the electromagnetic parts you can’t do without in EV powertrains, charging systems, and power management electronics. As electric vehicle designs keep getting more diverse and evolving, the companies that build coil winding machines are dealing with some never-before-seen demands—they need more customization options, specialized features, and advanced capabilities than ever before.

The EV revolution has moved beyond simply replacing internal combustion engines with electric motors. It has sparked an engineering renaissance that demands higher efficiency, greater power density, and more compact designs across all electromagnetic components. This article explores how these demands are reshaping the coil winding equipment industry, driving innovation in transformer winding equipment, and creating new paradigms in electromagnetic component manufacturing.

Market Expansion: Quantifying the Growth Trajectory

The global market for specialized coil winding equipment is experiencing robust growth, directly correlated with EV adoption rates. According to recent market research, the global high-voltage coil winding machine market was valued at approximately $519 million in 2024 and is projected to reach $977 million by 2031, reflecting a compound annual growth rate (CAGR) of 9.6% during this period .

This growth trajectory significantly outpaces many other industrial equipment sectors and underscores the profound impact of EV-driven demand. The Asia-Pacific region, particularly China, represents the largest and fastest-growing market for these specialized machines, corresponding with its dominance in EV production and adoption . Regional manufacturing hubs are responding to local supply chain demands with customized solutions specifically designed for the unique requirements of Asian EV manufacturers.

The expansion is not limited to high-voltage applications. The broader coil winding equipment market encompasses diverse machinery types including automatic and semi-automatic systems, each finding specialized applications within the EV ecosystem . From motor windings to specialized transformers for fast-charging infrastructure, each application demands tailored solutions with specific capabilities, driving further customization in the equipment market.

Technical Evolution: Beyond Conventional Winding Technologies

Traditional winding technologies are increasingly inadequate for the demanding specifications of next-generation EV components. The industry is responding with innovative approaches that improve performance, reduce size, and enhance manufacturing efficiency.

The Rise of Advanced Winding Configurations

Continuous Flow Winding (CFW) represents one of the most significant recent innovations in winding technology. This emerging technique combines advantages from both hairpin and wave winding methods while addressing their limitations. CFW enables remarkable improvements in key performance metrics, including power density of 16.8 kW/kg and torque density of 15.8 Nm/kg—substantial improvements over conventional approaches .

The technical advantages of CFW are particularly relevant for EV applications. The technology reduces axial winding dimensions by approximately 24% compared to traditional hairpin or wave winding methods . This compactness is crucial for EV designers seeking to minimize powertrain size while maximizing passenger and battery space. Additionally, CFW systems achieve superior heat dissipation through direct conductor cooling, addressing one of the fundamental challenges in high-performance EV motor design.

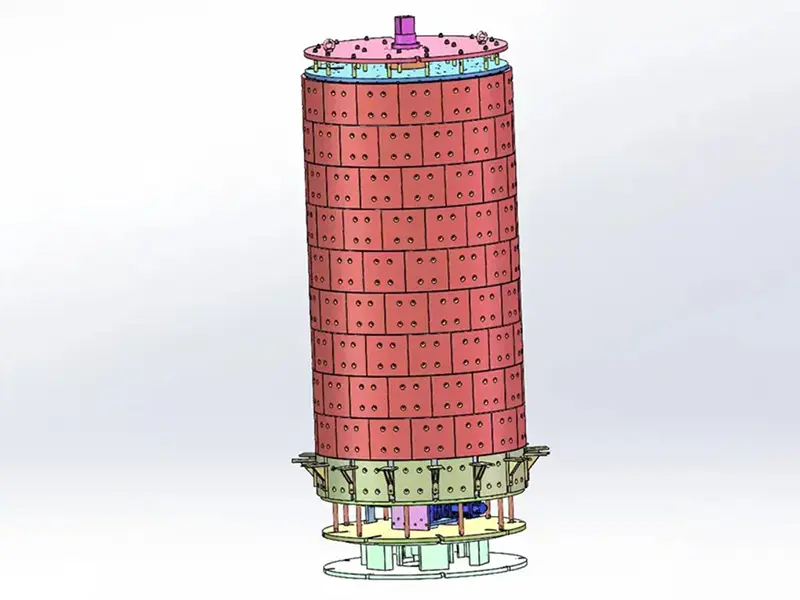

Specialized Winding for High-Voltage Applications

The industry-wide transition toward 800-volt architectural platforms in electric vehicles has created parallel demand for specialized transformer winding equipment capable of producing components for high-voltage systems . These systems require enhanced insulation capabilities, precise tension control, and specialized winding patterns to withstand higher electrical stresses and minimize losses.

Modern wire winding machine systems for high-voltage applications incorporate advanced features including closed-slot designs, which protect magnetic materials from harmonic influences, and sophisticated cooling channel integration for direct oil cooling of windings . These features require increasingly customized equipment configurations tailored to specific component geometries and performance requirements.

Customization Drivers: Where Standard Solutions Fall Short

Several key factors within the EV industry are propelling the movement toward customized coil winding solutions rather than off-the-shelf equipment.

Diverse Performance Requirements Across EV Segments

The performance requirements for electromagnetic components vary significantly across different EV segments. Economy-class vehicles prioritize cost-efficiency and manufacturing scalability, while performance and luxury segments demand maximum power density and exceptional thermal management. These divergent priorities necessitate different approaches to coil winding, with equipment manufacturers increasingly offering customized solutions tailored to each segment's specific needs.

Material Innovations Driving Equipment Adaptations

Advances in conductor materials, including rectangular copper flat wires and advanced insulation systems, require corresponding adaptations in coil winding equipment . Modern wire winding machine systems must handle these new materials without causing deformation or damaging delicate insulation layers—a challenge that often requires customized guidance systems, tension mechanisms, and handling procedures.

The transition to flat wire conductors for EV motors exemplifies this trend. These conductors offer improved space factors and thermal performance but present unique challenges in winding precision and deformation prevention during the insertion process . Equipment manufacturers have responded with specialized systems designed specifically for flat conductor winding, representing a significant departure from traditional round wire equipment.

Manufacturing Efficiency Demands

As EV production scales to millions of units annually, manufacturing efficiency becomes increasingly critical. Customized coil winding machine systems optimized for specific components can significantly reduce cycle times, minimize material waste, and enhance overall production throughput .

Advanced CFW systems, for instance, can achieve cycle times of approximately 83 seconds per stator with equipment overall effectiveness (OEE) reaching 85%—significantly higher than industry averages . These efficiency advantages are driving EV manufacturers to seek increasingly customized solutions optimized for their specific production environments and volumes.

Specialized Applications: EV-Specific Component Manufacturing

The diversification of EV components requiring specialized winding approaches represents a significant driver for equipment customization.

Electric Motor Production

EV motor manufacturing has spawned an entire category of specialized coil winding equipment designed specifically for traction motor production. These systems address the unique challenges of EV motors, including high slot-fill factors, precision winding patterns for optimized electromagnetic performance, and integration with advanced cooling systems .

The industry transition toward hairpin and wave winding technologies for EV motors has been particularly influential, requiring completely new categories of coil winding machine systems capable of forming, inserting, and welding pre-formed conductors rather than simply winding round wires . This transition represents one of the most significant equipment customization trends driven specifically by EV requirements.

High-Voltage Transformer Manufacturing

The proliferation of fast-charging infrastructure has created substantial demand for customized transformer winding equipment capable of producing high-voltage, high-frequency transformers for DC fast-charging stations. These components require precise winding techniques, advanced insulation systems, and robust construction to withstand the electrical and thermal stresses encountered in high-power charging applications .

Similarly, onboard chargers and DC-DC converters in EVs require specialized transformers that balance performance, size, and cost considerations—each potentially requiring slightly different winding approaches and thus customized equipment configurations.

Advanced Component Types

Beyond motors and transformers, modern EVs incorporate numerous specialized electromagnetic components each with unique winding requirements. These include:

Inductors for power electronics systems

High-voltage capacitors for filtering and energy storage

Specialized sensors for position and current monitoring

Actuators for various vehicle systems

Each component type may require different winding techniques, conductor types, and precision levels, further driving the trend toward customized coil winding equipment rather than universal solutions.

Technological Innovations in Coil Winding Equipment

The push for customization has catalyzed significant technological innovations in coil winding equipment design and capabilities.

Precision Tension Control Systems

Advanced tension control mechanisms have become increasingly critical for EV component manufacturing. Modern wire winding machine systems incorporate sophisticated tension control systems that maintain consistent wire tension throughout the winding process, preventing conductor deformation and ensuring consistent winding quality .

These systems are particularly important for flat wire and fine wire applications where even minor tension variations can impact component performance or cause insulation damage. The development of increasingly precise and responsive tension control represents a key innovation area driven by EV requirements.

Automated Manufacturing Systems

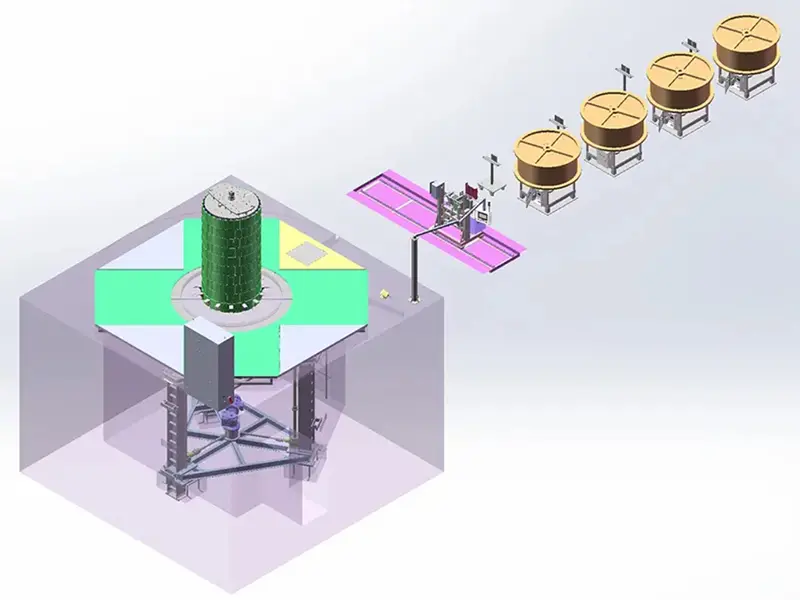

The transition toward fully automated winding cells represents another significant trend. These integrated systems combine multiple processes—including winding, termination, insulation, and testing—into seamless automated workflows specifically configured for particular components .

Modern coil winding machine systems for EV applications increasingly feature robotic component handling, automated quality verification, and digital process monitoring tailored to specific production requirements. This automation trend is particularly evident in high-volume EV component manufacturing, where consistency and throughput are paramount.

Digitalization and Industry 4.0 Integration

Contemporary transformer winding equipment and other coil winding systems increasingly incorporate digital technologies aligned with Industry 4.0 principles. These include:

Real-time process monitoring and data collection

Predictive maintenance capabilities to minimize downtime

Digital twin simulations for process optimization

Adaptive control systems that automatically adjust parameters

These digital capabilities enable more flexible equipment configurations and easier customization for specific applications, further supporting the trend toward tailored solutions rather than standard offerings.

Future Outlook: The Path Forward for Coil Winding Equipment

The customization trend in coil winding equipment shows no signs of abating as the EV industry continues its rapid evolution.

Emerging Technical Requirements

Several emerging technical developments will likely drive further equipment customization:

Higher-speed motors exceeding 20,000 RPM will require even more precise winding techniques and enhanced balancing capabilities

Integrated motor-reducer systems may demand specialized winding equipment configurations for unusual form factors

Next-generation wide-bandgap semiconductors will enable higher switching frequencies, potentially necessitating new winding approaches for associated magnetic components

Sustainable manufacturing initiatives may drive demand for equipment optimized for recyclable materials or reduced energy consumption

Market Structure Evolution

The coil winding equipment industry will likely continue consolidating around specialists capable of delivering highly customized solutions rather than standardized products. Equipment manufacturers with strong application engineering capabilities and flexibility in their design approaches will be best positioned to capitalize on EV-driven demand.

The growing complexity of EV winding requirements may also spur increased collaboration between component designers and equipment manufacturers early in the development process, ensuring that components are designed for manufacturability with available or developable winding technologies.

Conclusion: Customization as the New Normal

The electric vehicle revolution has fundamentally transformed the coil winding machine industry, elevating customization from a specialty service to a standard requirement. As EV technologies continue diversifying and advancing, the demand for specialized transformer winding equipment and other customized winding solutions will only intensify.

Equipment manufacturers that embrace this customization paradigm—developing flexible platforms, deepening their application expertise, and collaborating closely with EV component designers—will lead the next phase of industry evolution. The future of coil winding equipment is not in standardized machines serving multiple industries, but in highly specialized systems optimized for the unique and evolving requirements of electric vehicles.

The EV revolution has indeed spurred customization demand in coil winding equipment, but this trend represents more than a temporary market fluctuation—it signals a permanent restructuring of industry priorities and capabilities that will shape electromagnetic component manufacturing for years to come.