How is the Transformer Market Driving Technological Iteration and Innovation in Foil Winding Machines?

The global transformer market is going through a major makeover, thanks to growing energy needs and the big shift towards renewable energy sources. This change is having a direct effect on how foil winding machines, which are super important for making efficient, top-notch transformers, are being developed technologically.

As industries keep asking for transformers that can handle more power, come in smaller sizes, and are super reliable, there's never been a bigger demand for creative new solutions for transformer foil winding machines.

Wuxi Shuhong Machinery Technology Co., Ltd. will take you on an in-depth exploration of the major market-driven changes and how they are reshaping foil winding technology. We will also examine how these specialized machines are continuously upgraded to meet the demands of today's power systems.

Rising Demand for Energy Efficiency and High-Capacity Transformers

Energy efficiency has become a central focus in the transformer industry, driven by global sustainability initiatives and stricter regulatory standards. Transformers are integral to power distribution, and even minor improvements in their efficiency can lead to substantial energy savings. This push for efficiency is directly shaping the design and functionality of foil winding machines.

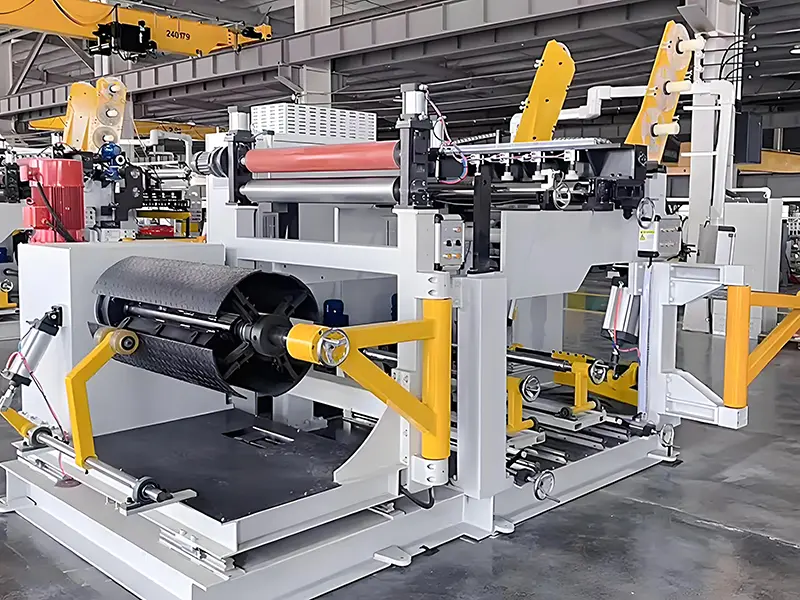

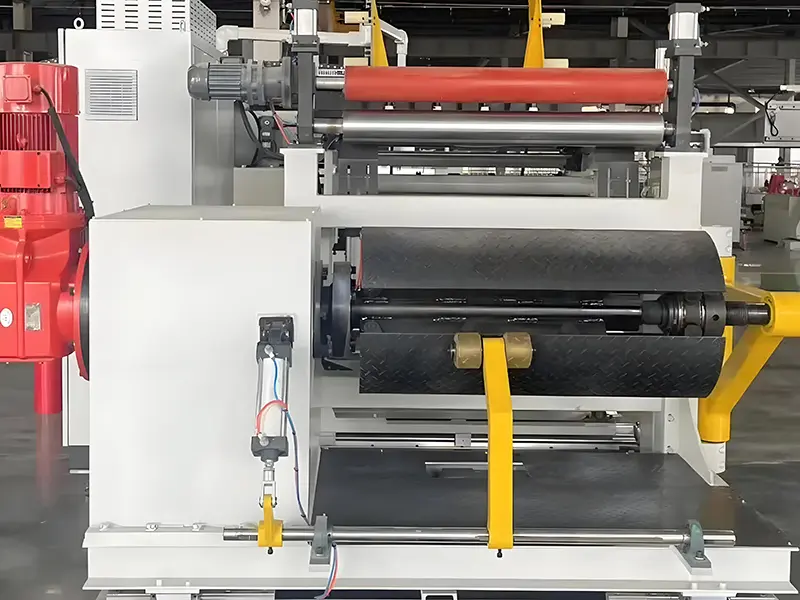

Foil windings, known for their excellent fill factor and thermal performance, are often preferred in high-current applications. The transformer foil winding machine is evolving to produce windings with tighter tolerances and improved geometric precision. This precision minimizes eddy current losses and enhances the overall efficiency of the transformer. For high voltage foil winding machine models, advancements include better control systems to handle the delicate insulation materials required for medium- and high-voltage applications. These machines now incorporate sophisticated tension control mechanisms to prevent damage to thin foil conductors and insulation films during the winding process, directly contributing to the production of more efficient and reliable transformers.

Technological Advancements in Foil Winding Machine Design

The design of foil winding machines is becoming increasingly sophisticated to address the complex requirements of modern transformers. One significant area of innovation is in the realm of medium-frequency, medium-voltage transformers, particularly for applications like solid-state transformers. Research from ABB Switzerland highlights the critical challenges in designing foil windings for these applications, where winding losses pose a major limitation to efficiency and power-processing capability. While Litz wire can be an alternative, foil windings remain a popular choice in many industrial applications due to their cost-effectiveness, ease of manufacturability, good fill factor, and high-temperature class.

Modern foil winding machines are addressing these challenges through advanced simulation and control technologies. The use of custom-developed design optimizers that employ 2D finite-element simulations allows for accurate modeling of AC effects within the foil windings. This enables manufacturers to optimize the winding design for specific operating conditions, such as different voltage levels and insulation technologies. Furthermore, the integration of automated features and precision engineering helps achieve the required consistency and quality. For instance, the development of floating frame devices with multiple roller sets has led to more compact foil winding structures, increased winding length, and enhanced equipment stability. These innovations are crucial for meeting the performance demands of next-generation transformers.

The Impact of High-Voltage and Specialty Transformer Applications

The growth in high-voltage transmission projects and specialized transformer applications is a major driver for the development of advanced high voltage foil winding machine equipment. High-voltage transformers require exceptional insulation integrity and precise winding geometry to withstand electrical stresses. Foil windings are well-suited for these applications, and the machines that produce them are adapting accordingly.

In high-voltage and medium-frequency transformers, the correlation between the rated insulation voltage and the frequency-dependent foil-winding losses is a critical design consideration. This has led to the development of foil winding machines capable of handling a wider range of insulation materials and conductor thicknesses with high precision. The machines are also being designed to accommodate the larger diameters and heavier weights often associated with high-voltage transformer coils. Beyond traditional power grids, foil winding technology finds relevance in other high-tech sectors. For example, high-current film-foil capacitors, which require precise winding, are essential components in fast-discharge applications for scientific research, lasers, and high-power microwave generators. The technological spillover from these demanding fields contributes to the overall advancement of transformer foil winding machine capabilities.

Market Competition and Globalization of Supply Chains

The global foil winding machine market is characterized by the presence of several key players distributed across North America, Europe, and Asia. This competitive landscape, where the top five manufacturers hold about 33% of the market share, fosters a continuous cycle of innovation as companies strive to differentiate their products. The dominance of fully automatic machines, which account for over 70% of the market, underscores the industry's shift towards higher productivity and reduced human intervention.

Global trade dynamics, such as shifting tariff policies, are also influencing the industry. These pressures are pushing manufacturers, particularly in China, to rethink their global supply chain strategies, moving from a model of pure export to establishing regional manufacturing centers and localizing production. This globalization forces machine builders to offer more versatile and robust foil winding machines that can be easily integrated into diverse production environments worldwide. The focus is on creating machines that are not only technologically advanced but also easier to service and support remotely, ensuring consistent performance and minimal downtime for international clients.

Future Outlook and Emerging Trends in Foil Winding

The future of foil winding machines is intrinsically linked to the evolving needs of the transformer industry. As the world moves towards smarter grids and greater integration of distributed energy resources, transformers will need to become more adaptive and efficient. This will require further refinements in winding technology.

One key trend is the increasing digitization and integration of Industry 4.0 principles into transformer foil winding machine operations. The adoption of IoT sensors and data analytics will enable real-time monitoring of the winding process, predictive maintenance, and seamless data exchange with factory management systems. This data-driven approach will help optimize production quality and traceability. Another area of potential growth is in the use of new materials. As transformer designs push the limits of existing materials, foil winding machines will need to adapt to handle novel conductor and insulation materials, such as advanced polymers or composites, which may offer better thermal or dielectric properties. The industry's ongoing research, as seen in institutions like BARC, which works on new extended foil and internal series configurations for capacitors, hints at the kind of innovative winding designs that may trickle down to transformer manufacturing in the future.

Conclusion

The transformer market is a powerful engine for innovation in the foil winding machine sector. The relentless pursuit of efficiency, capacity, and reliability in transformers is pushing machine manufacturers to develop more sophisticated, automated, and precise solutions. From handling the complexities of high voltage foil winding machine applications to adapting to global supply chain shifts, the evolution of these machines is a testament to the dynamic nature of the power industry. As energy systems continue to transform, the symbiotic relationship between transformer design and foil winding machine technology will undoubtedly yield even more advanced and capable equipment in the years to come.