How is Transformer Winding Equipment Adapting to the Growing Demand for High-Frequency Transformers in the EV Sector?

The electric vehicle (EV) revolution is accelerating, compelling manufacturing technologies to evolve in tandem. At the heart of this transformation lies the production of high-frequency transformers—critical components for efficient power conversion in EVs. Transformer winding equipment is undergoing a significant technological shift to meet the stringent demands of these next-generation components. This article explores the specific adaptations in winding machinery, focusing on precision, automation, and the handling of advanced materials necessary for the high-frequency transformers that power the future of mobility.

The evolution of this equipment is not merely incremental; it represents a fundamental re-engineering of processes to achieve unprecedented levels of accuracy and efficiency.

The Precision Engineering Imperative for EV Transformers

The performance of high-frequency transformers in electric vehicles hinges on extremely precise manufacturing. Unlike conventional transformers, those designed for high-frequency operation in EVs require minimal loss and maximal power density to ensure efficient power conversion and extended vehicle range.

Tighter Tolerances and Layering: Transformer winding machine technology has advanced to achieve near-perfect wire placement. Any inconsistency in winding tension or layering can lead to increased parasitic capacitance and leakage inductance, which severely degrades performance at high frequencies. Modern equipment utilizes sophisticated servo motors and real-time tension control systems to ensure each winding is placed with micron-level accuracy. This precision is crucial for managing the skin and proximity effects that become pronounced at the high switching frequencies—often reaching 500 kHz or more—found in EV power inverters and DC-DC converters.

Enhanced Process Control: The core of a high-frequency transformer often requires specific and consistent winding patterns to optimize the magnetic flux path and minimize core losses. Advanced wire winding machine models are now integrated with computer vision systems and laser measurement tools to verify each winding layer in real-time. This closed-loop control system immediately corrects any deviations, ensuring the final transformer product meets the exact electrical parameters required for reliable operation in the demanding environment of an electric vehicle.

The Shift Towards Full Automation in Production Lines

As the demand for EVs surges, the volume of required components follows suit. This has made automation a cornerstone of modern transformer production.

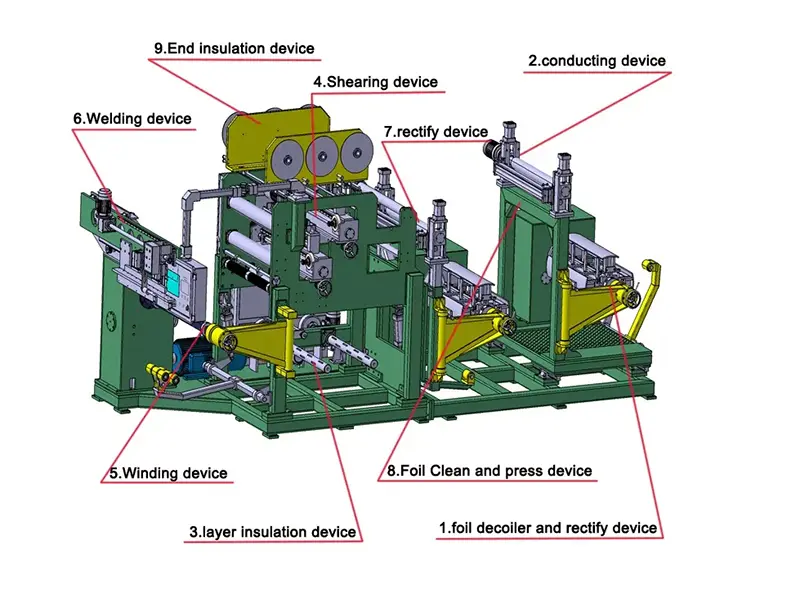

Unmanned Operations and Throughput: Automatic coil winding machine systems are increasingly deployed in fully automated production cells. These systems can operate continuously with minimal human intervention, dramatically increasing output while reducing labor costs and the potential for human error. They are often linked with automated material handling systems that feed wire, cores, and bobbins, and then transfer the wound components to the next stages, such as vacuum potting and testing.

Data Integration and Industry 4.0: Contemporary transformer winding equipment is a data-generating node in a smart factory. These machines collect vast amounts of process data—including winding speed, tension, temperature, and electrical test results—for each unit produced. This data is used for predictive maintenance, preventing unplanned downtime, and for full traceability. In the context of high-frequency transformers for EVs, where quality and reliability are non-negotiable, this data-centric approach allows manufacturers to guarantee performance and quickly trace any potential production issues.

Handling Advanced Materials and Complex Geometries

The move to high frequencies has driven the adoption of new materials and transformer geometries, which in turn has necessitated evolution in winding capabilities.

Compatibility with New Core Materials: To minimize losses at high frequencies, EV transformers increasingly use toroidal powder cores or other advanced alloys. These cores often have a closed shape, requiring specialized transformer winding machine designs with sophisticated shuttle, flyer, or needle-based winding heads to navigate the geometry. The equipment must be gentle yet precise to avoid damaging the core material while accurately placing the wire.

Embracing Planar and Custom Magnetics: Planar magnetics, which use flat windings on printed circuit boards (PCBs) to achieve a very low profile and excellent thermal performance, are gaining traction. The production of these components requires a different class of automatic coil winding machine that can handle the precise deposition and lamination of conductive materials. Furthermore, the trend towards custom magnetics to fit unique EV powertrain architectures demands flexible winding platforms that can be quickly reconfigured for different designs without significant downtime or retooling.

Direct Drivers from the Electric Vehicle Sector

The specific requirements of electric vehicles are directly influencing the R&D roadmaps of winding equipment manufacturers.

Power Density and Thermal Management: EVs prize every cubic centimeter. Therefore, high-frequency transformers must be as small and power-dense as possible. Transformer winding equipment is being refined to create windings with a higher fill factor, effectively packing more copper into a smaller volume to improve current handling and reduce resistive losses. Superior thermal management is also a direct result of precise winding, as evenly distributed windings facilitate better heat dissipation, a critical factor for reliability.

Meeting Stringent Automotive Standards: Components for the automotive industry must endure harsh conditions, including extreme temperatures, vibration, and humidity. The robustness of a transformer begins with its construction. Advanced wire winding machine systems contribute to this by producing windings that are mechanically secure and consistent, capable of withstanding high levels of mechanical shock and vibration. This inherent mechanical integrity is essential for meeting the long-term reliability standards expected in automotive applications.

The adaptation of transformer winding equipment is a critical, though often unseen, enabler of the electric vehicle industry's growth. Through remarkable advances in precision engineering, the widespread adoption of fully automatic coil winding machine systems, and the ability to process novel materials and complex geometries, this machinery is rising to the challenge. As EV technologies continue to advance towards higher voltages and faster switching speeds, the symbiotic relationship between transformer design and the transformer winding machine used to build it will only grow stronger, pushing the boundaries of what is possible in power electronics for sustainable transportation.