Shuhong Machinery releases the GZR-800 automatic winding machine, driving industrial upgrading.

With the continuous advancement of the global energy structure transformation, the power equipment manufacturing industry is facing a new wave of technological innovation. Against this backdrop, Wuxi Shuhong Machinery Technology Co., Ltd., a professional manufacturer in the field of winding equipment, recently officially launched its new generation GZR-800 (2+1) high-pressure coil automatic winding machine. The release of this product not only marks a significant breakthrough for the company in technological innovation but also provides the transformer manufacturing industry with an intelligent solution that can significantly improve production efficiency and product consistency.

As a critical link in power equipment manufacturing, the quality of the coil winding process directly affects the overall performance of transformers and other equipment. Especially in emerging application scenarios such as new energy power generation and electric vehicle charging facilities, higher standards are placed on the power density, energy efficiency, and reliability of transformers. Traditional manual winding methods can no longer meet the stringent requirements of modern manufacturing for precision, efficiency, and traceability. The introduction of the GZR-800 automatic winding machine provides timely and crucial technical support for the industry's transformation.

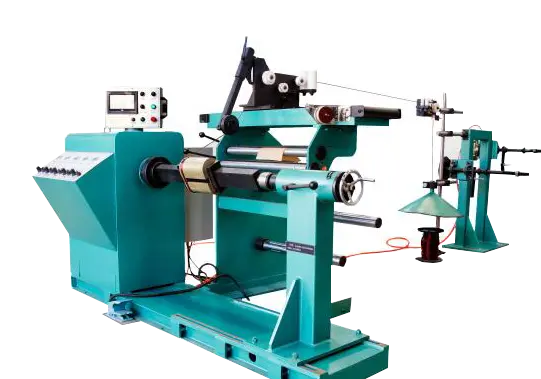

The equipment adopts an advanced modular design concept and is equipped with a high-performance servo control system and an intelligent human-machine interface. Its core technological innovations are reflected in several key performance indicators: First, the equipment supports flexible switching between parallel winding of double round wires and single flat wire winding, greatly improving production adaptability and process flexibility; second, the high-precision wire arrangement system can achieve precise control at the 0.01mm level, and combined with the constant tension wire feeding mechanism, ensures that the coil maintains a uniform and tight arrangement during the winding process; third, the entire machine uses core components from internationally renowned brands, including the Huichuan servo drive system, Schneider electric components, and TBI precision linear guides, providing reliable guarantees for the long-term stable operation of the equipment.

It is worth mentioning that the GZR-800 automatic winding machine has been specifically optimized for the transformer core winding process. By improving the tension control algorithm and wire path planning, the equipment can maintain a constant tension output during the winding process, ensuring a tight fit between the coil and the core. This feature is of great significance for improving the electrical performance and mechanical stability of transformers, effectively reducing energy loss and electromagnetic noise during equipment operation. In terms of practical application, the device has been validated on the production lines of several well-known transformer manufacturers. User feedback data shows that after adopting the GZR-800 automatic winding machine, coil production efficiency increased by an average of over 40%, and the product pass rate reached over 99.5%. At the same time, the device's touch screen control system supports multi-segment winding program storage, and the intuitive and user-friendly interface significantly reduces the learning curve for operators.

Wuxi Shuhong Machinery Technology Co., Ltd. has always regarded technological innovation as the core driving force of its development. The company has a complete R&D system and a professional technical service team, providing customers with comprehensive support from equipment selection to process optimization. With the successful launch of the GZR-800 (2+1) high-voltage automatic winding machine, the company will further consolidate its leading technological position in the winding equipment field.

Looking ahead, with the in-depth application of Industry 4.0 technology, winding equipment is developing towards greater intelligence and networking. Shuhong Machinery stated that it will continue to increase R&D investment to promote the application of new technologies such as the Internet of Things and big data in the field of winding equipment, helping the power equipment manufacturing industry achieve high-quality development. In this historical period of rapid development of the new energy industry, technological innovation will be a key force driving industry progress, and the launch of the GZR-800 automatic winding machine is a powerful manifestation of this development trend.

Wuxi Shuhong Machinery Technology Co., Ltd. will continue to cultivate the winding equipment field, constantly launching technological products that meet market demands, contributing professional strength to the transformation and upgrading of the transformer and power equipment manufacturing industry, and assisting in the leapfrog development of "Made in China" to "Intelligent Manufacturing in China."