Silicon Steel Swing Shear Machine: A Revolutionary Breakthrough in Transformer Core Manufacturing

Innovation and Application of Precision Cutting Technology

In the field of modern power equipment manufacturing, the quality of transformer cores directly affects the operating efficiency of the entire power system. As the core component of a transformer, the manufacturing precision of the transformer core directly determines the energy consumption level and operational reliability of the transformer. With the increasing demand for high-efficiency and energy-saving equipment in the power industry, traditional core manufacturing technologies are no longer sufficient to meet the precision manufacturing requirements of modern power equipment. It is against this backdrop that the transformer core cutting machine has emerged, becoming a crucial force in driving technological innovation in the industry.

Core Technological Breakthroughs in Advanced Cutting Systems

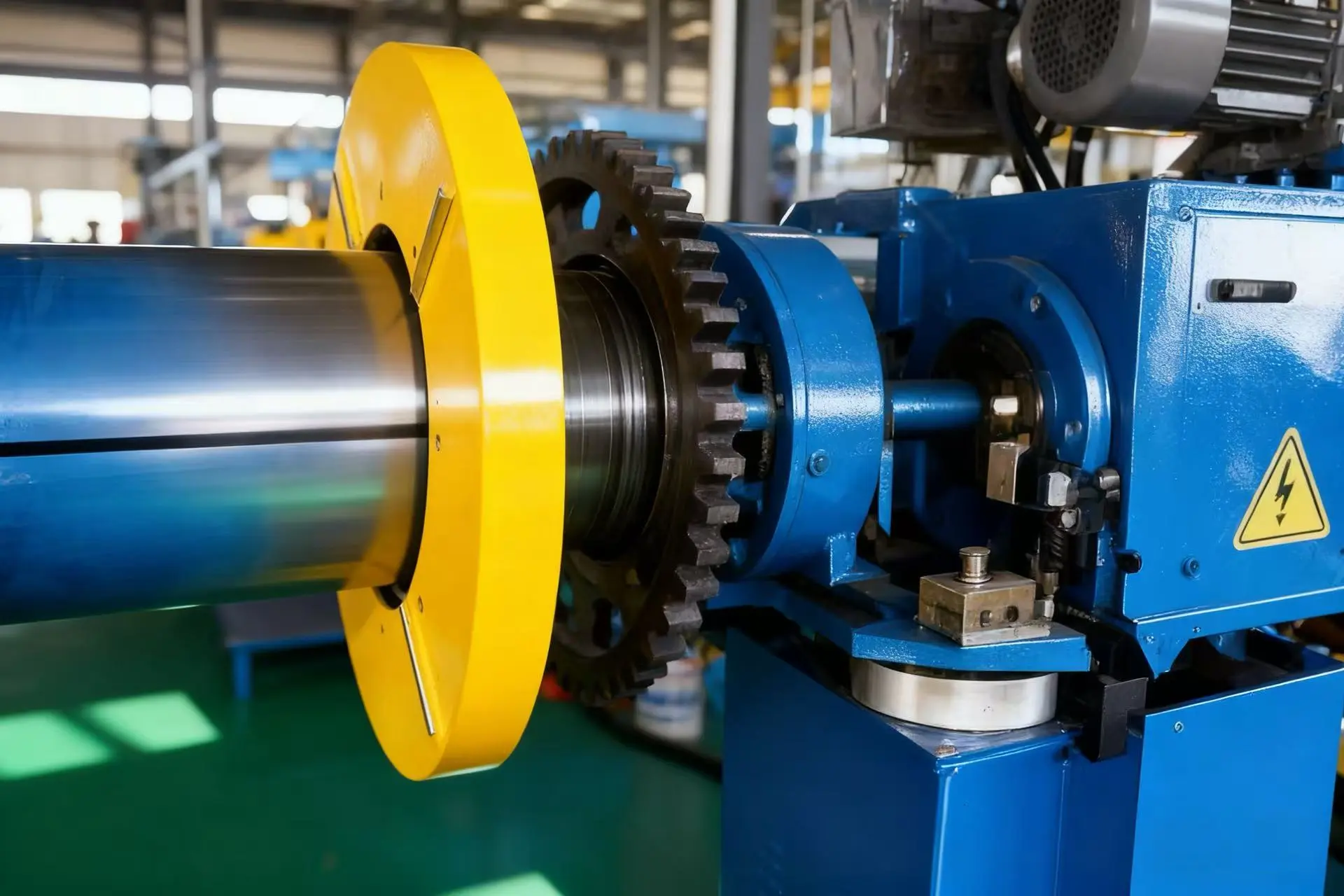

The core technology of the silicon steel swing shear machine lies in its innovative servo-driven swing cutting system. This system utilizes advanced mechanical design and precision control technology to achieve multi-angle, high-precision cutting operations. Compared with traditional fixed-type cutting equipment, the swing cutting system offers greater flexibility and adaptability. In actual production, the equipment can automatically adjust the cutting angle according to preset parameters, with a rotation angle accuracy of ±0.1 degrees, fully meeting the production needs of various complex core structures.

Comprehensive Improvement in Precision Manufacturing Capabilities

In terms of manufacturing precision, the transformer core cutting machine demonstrates outstanding performance. The equipment's cutting length range covers 200-5000 millimeters, with a fixed-length accuracy better than ±0.025 millimeters, and the cutting burr height is strictly controlled within 0.02 millimeters. These technical indicators not only meet the current industry requirements for precision manufacturing but also lay the foundation for higher standards of core manufacturing in the future. It is worth mentioning that the hard alloy cutting tools used in the equipment have excellent wear resistance, with a service life of over 2 million cuts before resharpening, significantly reducing equipment maintenance costs and downtime.

Integrated Innovation of Intelligent Production Systems

Another important feature of modern transformer core cutting machines is their highly intelligent control system. This system integrates advanced programmable controllers and human-machine interfaces, achieving automated control of the entire process from parameter setting to production execution. Operators only need to input relevant parameters on the touch screen, and the equipment can automatically complete a series of operations including unwinding, feeding, positioning, cutting, and stacking. This intelligent production mode not only significantly improves production efficiency but also significantly reduces manual operation errors, ensuring product consistency.

Technical Advantages of the Multifunctional Integrated System

In addition to basic shearing functions, the new generation transformer core cutting machine integrates several advanced features. The online punching system can perform precise punching operations with hole diameters of 8-20 mm simultaneously with shearing, with hole position tolerance controlled within ±0.05 mm. The integration of a V-shaped notch system allows the equipment to meet the manufacturing needs of different types of transformer cores. The integration of these functions not only reduces production steps and improves overall efficiency but also ensures precision matching between each process.

Technical Innovations of the High-Performance Drive System

In terms of the drive system, the equipment uses high-performance servo motors and precision transmission devices. The feeding system uses a high-torque AC servo motor, with a feeding speed of up to 100 meters/minute and a positioning accuracy of ±0.02 mm. This high-speed, high-precision feeding system ensures the continuity and stability of the shearing operation. At the same time, the linear guides and ball screws used in the equipment are from internationally renowned brands, guaranteeing the long-term operating accuracy and reliability of the equipment.

Process Innovation of the Automated Stacking System

To address the specific needs of transformer core production, the transformer core cutting machine is also equipped with an advanced automated stacking system. This system can automatically complete the separation and stacking of laminations according to the production rhythm, with a maximum stacking length of up to 2.4 meters. The high degree of automation of the stacking system allows it to perfectly integrate with the main production line, achieving a fully automated production process from raw materials to finished products. This integrated production model significantly reduces labor costs and improves production efficiency.

Market Opportunities in the Context of Energy Transition

With the global energy structure transformation and the upgrading of power systems, the market demand for high-efficiency and energy-saving transformers continues to grow. As a key equipment for transformer core manufacturing, the silicon steel slitting machine is facing unprecedented development opportunities. According to statistics, the global transformer market is expected to grow at an average annual rate of 4.5% in the next five years, with the market share of high-efficiency and energy-saving transformers continuously expanding. This market trend provides ample space for the development of transformer core cutting equipment.

Future Development Trends and Technological Outlook

Looking ahead, transformer core cutting technology will develop towards greater intelligence and integration. With the in-depth application of industrial internet technology, the new generation of cutting equipment will achieve real-time collection and analysis of production data, optimizing production process parameters through big data technology. At the same time, the equipment will place greater emphasis on energy conservation and environmental protection, adopting more efficient power systems and optimized mechanical structures to reduce energy consumption. Furthermore, modular design will become an important direction for future equipment development, allowing for flexible configuration based on customer needs.

Driving Force for Industrial Upgrading

The technological upgrading of transformer core cutting machines not only improves the technical level of individual equipment but, more importantly, drives the industrial upgrading of the entire transformer manufacturing industry. By providing higher precision and more efficient manufacturing equipment, these machines help transformer manufacturers improve product quality, reduce production costs, and enhance market competitiveness. Simultaneously, the widespread application of advanced manufacturing technologies also promotes the development of related supporting industries, forming a virtuous cycle of industrial chain synergy.

Conclusion

As a key piece of equipment in transformer core manufacturing, the technological development level of silicon steel shearing machines directly impacts the progress of the entire power equipment manufacturing industry. Currently, with the continuous emergence of new technologies and the ongoing changes in market demand, transformer core cutting equipment is facing significant opportunities for transformation and upgrading. In the future, through continuous technological innovation and market expansion, these devices will undoubtedly play an even more important role in promoting the high-quality development of the power equipment manufacturing industry, providing strong technical support for global energy transformation and power system upgrading.