Technological Evolution of Foil Winding Machines and the Engineering Breakthrough of the BRJ-1600-II

As the global energy transition and smart grid construction enter a critical stage, the transformer manufacturing industry faces unprecedented pressure for technological upgrades. The power system's increasing demands for transformer energy efficiency, reliability, and intelligence are directly driving profound changes in coil manufacturing processes. As a key piece of equipment in the transformer production process, the technical level of the foil winding machine directly affects the performance and manufacturing efficiency of transformer products. The newly launched BRJ-1600-II multi-layer foil winding machine, with its innovative design concept and advanced technical configuration, not only represents the latest achievements in foil winding equipment development but also provides a practical technological path for the digital transformation of the transformer manufacturing industry.

I.Analysis of the Strategic Evolution Path of Foil Winding Machine Technology

The technological development of foil winding machines has always been highly coordinated with changes in transformer design concepts and manufacturing requirements. Traditional transformers mostly use wire-wound structures, which are simple in process but have inherent defects such as uneven current distribution and limited heat dissipation performance. As large capacity, low loss, and high reliability become the mainstream trend in transformer design, foil windings have gradually become the preferred solution due to their unique structural advantages. Foil winding technology can achieve more uniform current distribution, more effective heat dissipation, and higher space utilization, which gives it a significant advantage in the manufacturing of high-voltage, large-capacity transformers.

From a technological development perspective, foil winding machines have undergone a significant transformation from mechanization to intelligence. In the initial mechanized stage, the equipment mainly relied on manual operation and simple mechanical transmission, resulting in low production efficiency and difficult quality control. After entering the electrification stage, the equipment began to introduce basic automation functions, achieving preliminary parameter control, but still had limitations such as insufficient precision and poor adaptability. Currently, the intelligent stage, represented by the BRJ-1600-II, achieves a comprehensive improvement in equipment performance by integrating precision sensing technology, adaptive control systems, and digital process management. Modern foil winding machines require material processing accuracy to reach the micron level, the tension control system to maintain millinewton-level stability during dynamic processes, and multi-layer insulation laying to require sub-millimeter positioning accuracy. These stringent technical requirements make high-end foil winding machines typical representatives of multi-disciplinary technology integration.

II. Systematic Technological Innovations of the BRJ-1600-II

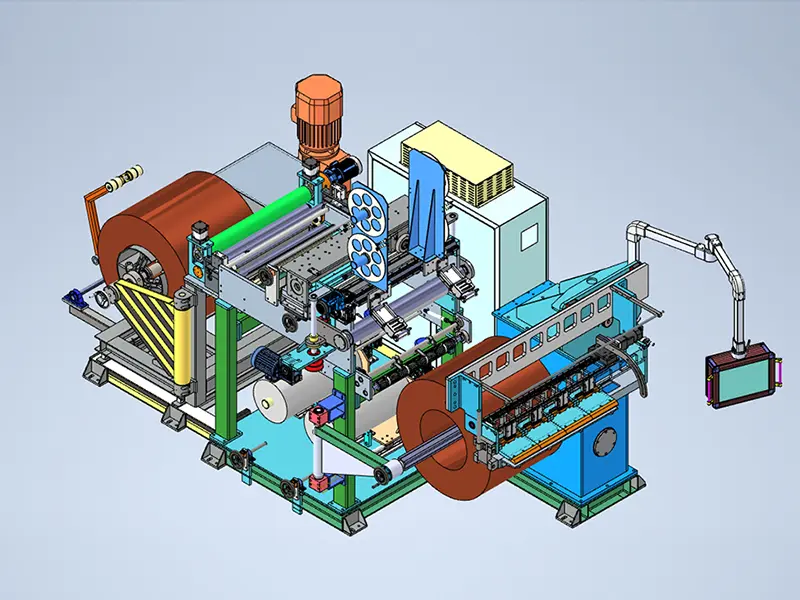

The BRJ-1600-II has achieved significant breakthroughs in multiple core technological aspects, particularly demonstrating outstanding performance in material handling systems, precision control systems, and welding processes.

In the material handling process, the equipment adopts an innovative dual-unwinding system configuration, coupled with a hydraulic tension control mechanism, enabling continuously adjustable constant tension output within the range of 0-18000 Newtons. This design not only adapts to the different mechanical properties of various materials such as copper and aluminum foil, but more importantly, it solves the tension fluctuation problem commonly found in traditional equipment during start-up and shutdown. Actual test data shows that the tension fluctuation during acceleration and deceleration phases can be controlled within ±3%, far superior to the industry average. The material reel adopts a hydraulic one-button telescopic mechanism, ensuring a load capacity of 5000 kg while achieving rapid material change operations, reducing the traditional 15-minute operation time to less than 5 minutes, significantly improving the equipment's operating efficiency.

In terms of precision control, the equipment has built a hierarchical collaborative control system. The basic level uses photoelectric edge detection and correction technology, achieving a positioning accuracy of ±0.5 mm through multi-sensor data fusion processing. The intermediate control adopts a composite control strategy of magnetic powder clutch and servo motor, ensuring a high level of tension control accuracy of ±2%. Notably, the system framework implements an electric one-button forward and reverse function, eliminating the need for external track support. This design saves equipment space and improves operational reliability. At the macroscopic level, the overall machine movement is centrally coordinated by a Siemens PLC system, using a distributed IO architecture for time-optimized control of each subsystem. At a maximum winding speed of 20 revolutions per minute, the synchronization error of each subsystem is less than 0.1 seconds.

The welding process utilizes TIG AC/DC argon arc welding technology, combined with a linear guide and ball screw transmission system, to achieve precise positioning of the welding head within a 1600 mm range. The system has an adaptive welding parameter adjustment function, which can adjust process parameters in real time according to changes in foil thickness, ensuring a welding surface fusion rate of no less than 95%, while reducing the flatness error after welding by more than 60%.

III.Flexible Production Capacity and Digital Integration

To adapt to the small-batch, multi-variety production characteristics of modern transformer manufacturing, the BRJ-1600-II has been comprehensively optimized at both the mechanical structure and control system levels. The equipment adopts a modular design concept, and the winding shaft supports a quick-change function, allowing for switching between different specifications within 30 minutes. The pressure roller system uses a V-shaped structure design, with an adjustable length ranging from 288 to 1198 millimeters, accommodating various coil cross-sections such as circular, rectangular, and elliptical. The control system pre-sets 100 process recipes, supports one-click recall, and is equipped with power-off memory protection to ensure the continuity and stability of the production process.

Digital integration capabilities are a key feature of the equipment. A 10.4-inch touchscreen provides an intuitive human-machine interface, displaying key parameters such as winding turns, tension values, and operating speed in real time. The equipment is equipped with standard communication interfaces, supporting the OPC UA protocol, enabling seamless integration with the factory MES system. The data acquisition system can completely record the entire process information of each production batch, providing support for process optimization and quality traceability. Predictive maintenance functions monitor the operating status of key components, enabling fault warning and on-demand maintenance, significantly improving equipment utilization.

IV. Industry Impact and Technological Development Prospects

The technological innovations of the BRJ-1600-II have had a positive impact on multiple levels. In terms of energy efficiency, the coils it manufactures can reduce transformer no-load losses by 15-20%. In terms of production efficiency, the increased level of automation reduces manual intervention by 70% and shortens the production cycle by 35%. In terms of quality control, digital process management ensures a product qualification rate of over 99.5%. A more far-reaching impact is that the progress of foil winding machine technology is driving the collaborative upgrading of the entire transformer industry chain, leading to positive changes from upstream material supply to downstream product design.

Looking ahead, foil winding machine technology will further develop towards intelligence and integration. New technologies such as machine vision inspection, digital twin optimization, and artificial intelligence control will be gradually applied to equipment upgrades. At the same time, the concept of green manufacturing will be deeply integrated into product design, and energy-saving technologies and material recycling will become standard features of the next generation of equipment. With the continuous emergence of new application scenarios such as flexible DC power transmission and renewable energy integration, the technical adaptability of foil winding machines will become a key factor in determining the level of transformer manufacturing.