The Smart Factory Revolution is Knocking: Is Your Corrugated Sheet Forming Machine Ready?

Introduction: The Imperative of Digital Transformation

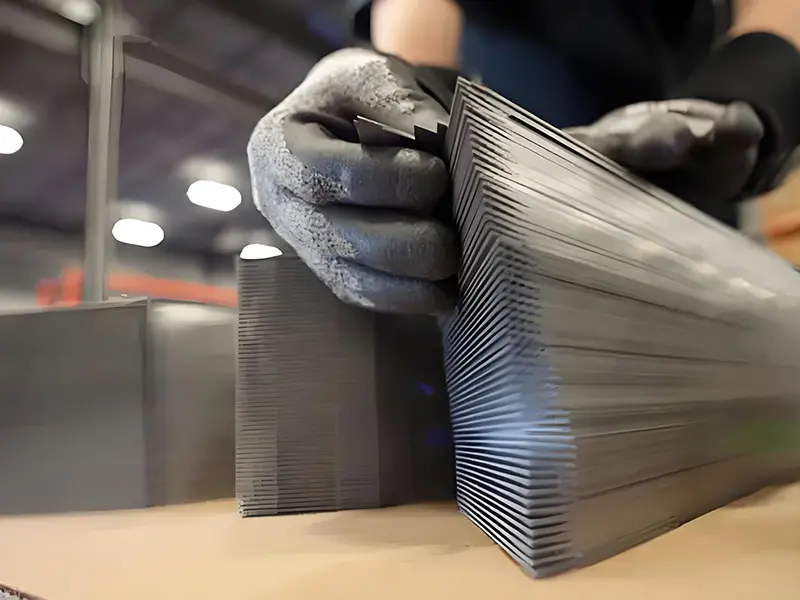

The manufacturing landscape is undergoing a profound transformation, driven by the principles of Industry 4.0. For operations reliant on corrugated sheet forming machines, this shift is not a distant future but a present-day imperative. These machines, long the workhorses of industries from packaging to automotive and construction, are now at the crossroads of legacy engineering and smart technology. The question is no longer if to upgrade, but how to evolve from isolated production units into interconnected, intelligent systems. The integration of smart sensors, adaptive controls, and data-driven processes is redefining productivity, quality, and flexibility, pushing the boundaries of what these formative machines can achieve. This article explores how the modern corrugated sheet forming machine is being reinvented for the age of digital manufacturing.

The Self-Learning Machine: From Reactive to Predictive Operations

At the heart of the Industry 4.0 revolution for forming equipment is the concept of self-optimization. Traditional machines operate on fixed parameters, but next-generation systems can now monitor and correct their own processes in real-time.

A pioneering example is the development of a smart, self-learning forming process. In this setup, the tooling itself gains intelligence. It communicates directly with the press control system, creating a closed-loop where quality is continuously verified. If a sensor detects that a sheet has been bent outside of tolerance, the tool can autonomously signal the press to stop and compensate for the fault within the same production stage. This is achieved through sophisticated algorithms that manage data from sensors and actuators, feeding information into a dynamic correction model. The result is a significant stride toward zero-fault production, which is particularly transformative for small batches, offering unprecedented flexibility and efficiency gains .

This philosophy of adaptation is also reaching the bending stage. Advanced press brakes now feature integrated laser scanning systems that constantly measure the bend angle. The CNC control unit uses this real-time data to instantly adjust the depth of the upper slide, accounting for material variations like thickness or grain direction. This ensures consistently accurate bends, batch after batch, moving quality control from a post-process inspection to an in-process correction .

Seamless Integration: The Role of Automatic Welding and Robotics

Forming is often only one step in the production of corrugated components. The subsequent joining and assembly processes are critical, and here, automation plays a pivotal role. The corrugated sheet automatic welding machine is a key enabler of this seamless workflow.

In applications such as the construction of LNG membrane tanks or railway vehicles, specialized robotic welding systems are deployed. These robots are designed with a deep understanding of the corrugated geometry. Researchers have developed robots that use kinematic modeling and the Monte Carlo method to analyze their effective workspace, ensuring they can navigate the complex contours of a corrugated surface. Furthermore, adaptive control systems, such as those based on Fuzzy PID algorithms, allow these robots to maintain a tracking error of less than 0.3 mm during operation. This high precision ensures consistent weld quality across the uneven terrain of the corrugations, a task that is challenging and error-prone when performed manually .

Similar innovations are found in the automotive sector. Patent filings describe automatic roll welding devices for stainless steel vehicle corrugated plates. These systems use multiple sets of rolling support mechanisms and guide pressing units to hold the corrugated plate firmly in place during welding. This precise control solves traditional problems like weld-through, excessive reinforcement, and inconsistent weld size, which are crucial for the subsequent installation of other components like aluminum honeycomb floors .

The Intelligent Core: Transformers, Coils, and Adaptive Power

The performance of any welding subsystem within an automated forming cell hinges on its power source. The evolution of the welding machine transformer type is a testament to the move toward greater control and efficiency.

The fundamental welding machine transformer type remains a core component, a special step-down transformer designed to provide high current at low voltages. Its key characteristic is a steeply drooping volt-ampere characteristic, which ensures a stable arc and prevents excessive current during accidental short-circuiting, such as when the electrode touches the workpiece. The output current is often finely tuned by adjusting the air gap within an associated reactor core, a robust and reliable technology .

Modern inverters, which still rely on advanced transformer and rectifier technology, have taken this further. They are smaller, more energy-efficient, and offer superior control. By using silicon-controlled rectifiers (SCRs) in a bridge configuration, these power supplies can precisely convert AC line power to the DC power needed for welding, providing operators with extensive control over the welding arc characteristics .

Underpinning all high-performance transformers and motors in this ecosystem is the precision art of welding machine coil winding. The manufacturing of these coils is critical to the efficiency, reliability, and thermal performance of electrical components. Modern winding technologies focus on creating efficient electrical wound products through highly automated processes. The knowledge encapsulated in fields like coil winding ensures that the transformers, actuators, and servo motors that drive a modern corrugated sheet forming machine are themselves masterpieces of production-friendly design and operational reliability .

Building the Ecosystem: Data, Connectivity, and the Future Factory

An individual smart machine is powerful, but its true potential is unlocked when it is part of a fully integrated ecosystem. This is the vision of the "Corruverse" or the "smart factory," where a corrugated sheet forming machine is not a standalone island but a node in a networked production system.

This involves the integration of forming, welding, and material handling with a central data management platform. Operational data from the forming press, the corrugated sheet automatic welding machine, and logistics systems are collected and analyzed. This allows for real-time performance monitoring (KPI), predictive maintenance—where machines flag potential failures before they cause downtime—and seamless data exchange with enterprise resource planning (ERP) systems .

Such a data-driven environment enables holistic optimization. For instance, the M2P® operational model employed by some machinery manufacturers involves a strategic partnership with clients to continuously optimize production processes. The goal is to tackle challenges like performance fluctuations, skilled labor shortages, and inefficient line configurations through data analysis and strategic adjustments, leading to sustained improvements in overall equipment effectiveness (OEE) .

Conclusion: Embracing the Smart Forming Revolution

The journey toward an Industry 4.0-ready corrugated sheet forming machine is multifaceted. It encompasses the self-correcting intelligence of the forming process itself, the precision of integrated robotic welding, the reliable power of advanced welding machine transformer type systems, and the foundational quality of welding machine coil winding. Ultimately, these technological threads are woven together by a connective fabric of data and digital integration. For forward-thinking manufacturers, investing in this holistic upgrade is no longer merely about keeping pace with competitors; it is about future-proofing their operations, unlocking new levels of quality, agility, and efficiency in an increasingly demanding global market. The smart forming revolution is here, and the time to prepare is now.