Oil-Immersed Cooling Transformer for Industrial Use

Product Specification

Basic Information

| Item | Specification |

| Product Model | Example: S11-M-500/10, S13-R-1000/20, S15-H-2500/35 (S=Three-Phase; 11/13/15=Efficiency Class; M/R/H=Structural Type; Capacity kVA/HV kV) |

| Rated Capacity(Sn) | 30kVA~5000kVA (ONAN: 100% rated capacity; ODAF: 130%; ODWF: 160%) |

| Phase/Frequency | Three-Phase (standard); 50Hz/60Hz (±1% tolerance, customizable for 400Hz special use) |

| Connection Group | Dyn11 (default for distribution), Yd11 (for power transformer); Yyn0 (optional) |

| Cooling Type | ONAN (Oil Natural Air Natural) / ODAF (Oil Directed Air Forced) / ODWF (Oil Directed Water Forced) |

Operating & Environmental Conditions

| Ambient Temperature | -25℃~40℃ (standard); -40℃~45℃ (low-temperature/high-temperature models with modified oil). |

| Altitude | ≤1000m (derate 5% at 1500m, 10% at 3000m, 15% at 4000m). |

| Humidity | ≤90% @25℃ (no condensation); ≤50% @40℃. |

| Seismic Resistance | GB 50260-2013 / IEC 60076-11, 7-degree intensity (0.15g acceleration); 8-degree optional. |

| Protection Class | IP23 (outdoor, dust/rainproof) / IP20 (indoor). |

Losses & Impedance (Typical Values by Efficiency Class)

| Efficiency Class | Parameter | 500kVA/10kV Example | Test Condition |

| S11 (IEC IE1) | No-Load Loss (Po) | ≤810W | Rated voltage/frequency |

| Load Loss (Pk) | ≤5200W | Rated current, 75℃ | |

| S13 (IEC IE2) | No-Load Loss (Po) | ≤650W (20% lower than S11) | Rated voltage/frequency |

| Load Loss (Pk) | ≤4800W | Rated current, 75℃ | |

| S15 (IEC IE3) | No-Load Loss (Po) | ≤520W (36% lower than S11) | Rated voltage/frequency |

| Load Loss (Pk) | ≤4500W | Rated current, 75℃ | |

| All Classes | Short-Circuit Impedance (Uk%) | 4%~6% (10kV 级); 6%~8% (35kV 级) | 75℃, ±10% tolerance |

| No-Load Current (Io%) | ≤1.0% (30~250kVA); ≤0.6% (≥315kVA) | Rated voltage |

Efficiency Compliance: GB 20052-2024 Class 2 (S11/S13) / Class 1 (S15); IEC 60076-11 IE1/IE2/IE3

Example S13-500/10 Key Specs

| Item | Value |

| Rated Capacity | 500kVA |

| HV/LV Voltage/Current | 10kV/28.87A; 0.4kV/721.7A |

| No-Load/Load Loss | ≤650W / ≤4800W |

| Short-Circuit Impedance | 4.5% |

| Cooling Method | ONAN |

| Core Material | 30Q130 Silicon Steel |

| Protection Class | IP23 |

Customizable for special voltages (e.g., 6.3kV, 13.8kV), high-altitude (≥3000m), or explosion-proof (Ex d IIB T4) requirements. All parameters verified by SGS/Intertek.

Advantages

1. Superior Heat Dissipation Efficiency

Leveraging the high thermal conductivity of insulating oil, the transformer efficiently transfers heat generated by internal coils and cores to the tank (and external radiators). This enables stable operation even under high load or long continuous working conditions, preventing overheating-induced component damage and ensuring consistent power output.

2. Excellent Insulation Performance

Insulating oil not only dissipates heat but also enhances electrical insulation between internal parts (e.g., coils, iron cores). It effectively isolates air, moisture, and dust, reducing the risk of leakage or short circuits. This advantage makes the transformer highly reliable in humid, dusty, or harsh industrial environments.

3. Strong Overload Capacity

The oil-immersed structure and optimized heat dissipation allow the transformer to withstand short-term overloads (e.g., sudden power surges in industrial production or peak civilian electricity use). Its ability to absorb and dissipate excess heat quickly minimizes performance degradation, avoiding unexpected shutdowns.

4. Long Service Life

The sealed oil tank protects internal components from external corrosion, dust, and mechanical wear. Additionally, high-quality insulating oil maintains stable performance over time, slowing the aging of coils and insulation materials. The transformer’s design life typically exceeds 20 years, reducing the frequency of equipment replacement.

5. Low Maintenance Requirements

The sealed structure reduces exposure to external contaminants, lowering the need for frequent internal cleaning or part replacement. Routine maintenance only involves periodic checks of oil level, oil quality, and tank tightness—simplifying operations and cutting long-term maintenance costs.

6. Suitable for High-Voltage Scenarios

Due to its excellent insulation and heat dissipation, the Oil-Immersed Transformer is widely used in high-voltage power grids, large industrial plants, and infrastructure projects (e.g., power transmission between substations). It meets strict voltage resistance standards, ensuring safe and efficient high-power transmission.

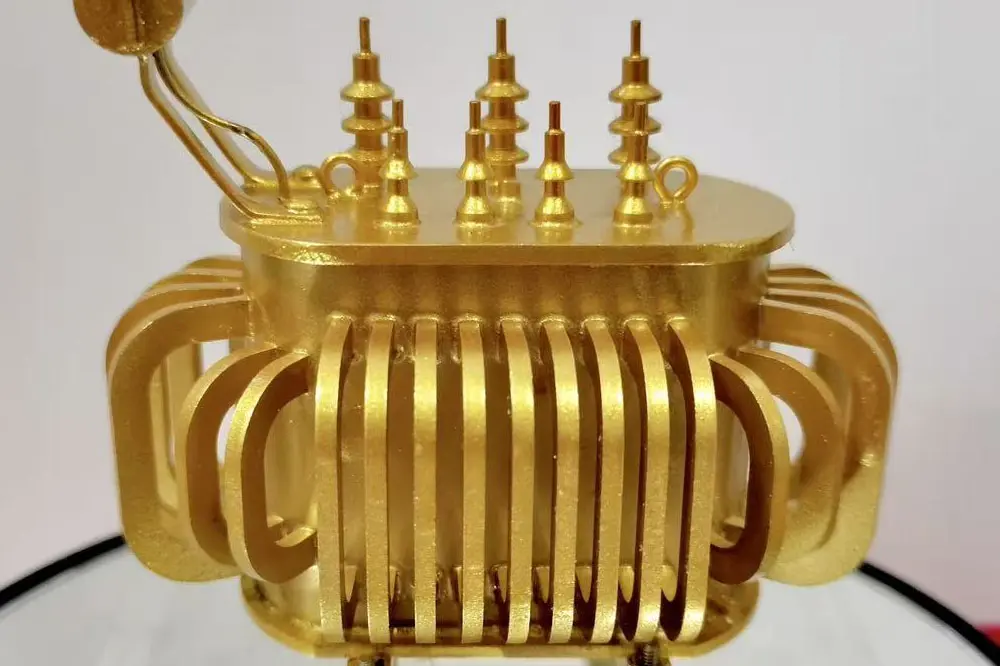

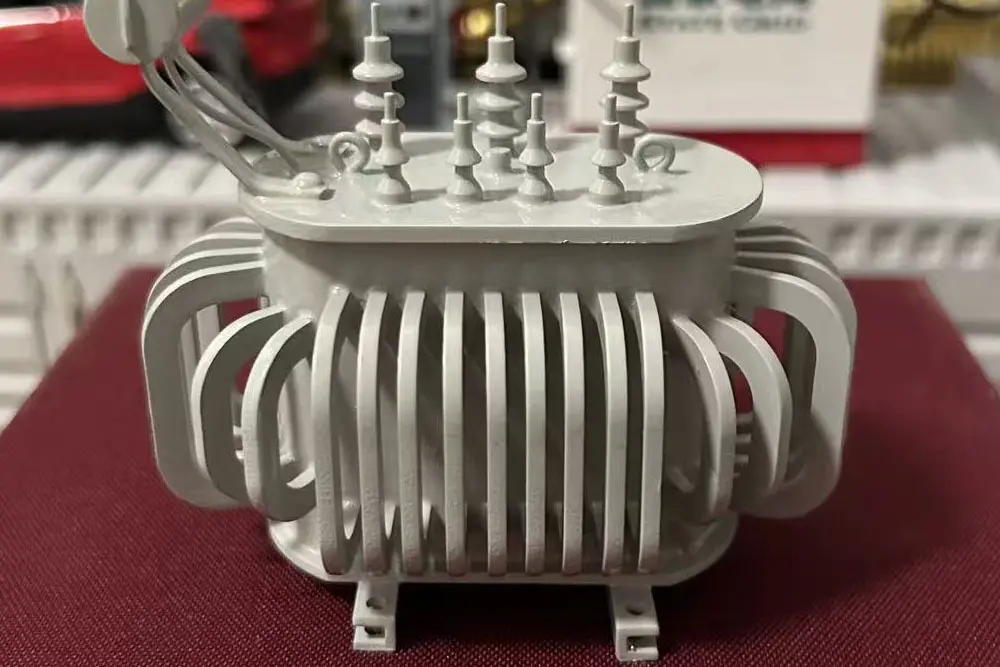

Product Display

Application

I. Power System: Core Equipment for High-Voltage Transmission & Distribution

As a cornerstone of power grids, the Oil-Immersed Transformer is indispensable for voltage conversion and power transmission, especially in:

● High-voltage power transmission networks: It is used in long-distance power transmission between regional power grids (e.g., from power plants to central substations). Its excellent insulation and heat dissipation enable stable operation under high voltage (110kV, 220kV, or even 500kV) and large current, minimizing energy loss during long-distance transmission.

● Substation voltage transformation: Installed in primary and secondary substations, it steps down high-voltage power (from transmission lines) to medium/low voltage (10kV, 0.4kV) for subsequent distribution to industrial users and residential areas, matching the voltage requirements of different end-users.

● Urban & rural distribution networks: For areas with high power demand or large coverage (e.g., suburban industrial zones, rural townships), it adapts to fluctuating loads and harsh outdoor conditions (temperature changes, humidity), ensuring reliable power supply to scattered users.

II. Industrial Sector: Reliable Power Supply for Heavy-Duty Operations

Its ability to withstand high loads and harsh environments makes it a top choice for industrial scenarios with continuous, high-intensity power needs:

● Heavy industry & manufacturing: Applied in steel mills, chemical plants, and machinery factories, it powers high-power equipment (e.g., blast furnaces, chemical reactors, production lines). Its strong overload capacity copes with sudden power surges during peak production, while its sealed structure resists dust, corrosive gases, and mechanical vibrations.

● New energy power generation supporting: Used in solar photovoltaic (PV) and wind power plants as "step-up transformers". It boosts the low-voltage electricity generated by PV panels or wind turbines to high voltage, enabling efficient integration into the national power grid—critical for large-scale new energy utilization.

III. Civil Infrastructure & Large-Scale Buildings

For civil scenarios requiring stable, long-term power supply and low maintenance, it is widely adopted in:

● Large commercial & public buildings: Installed in shopping malls, hotels, hospitals, and airports, it provides continuous power for air conditioning, elevators, lighting, and medical equipment. Its long service life (over 20 years) and low maintenance needs reduce operational costs for building managers.

● Data centers: Data centers operate 24/7 with high power density. The Oil-Immersed Transformer’s efficient heat dissipation reduces the load on the cooling system (less heat output = lower AC energy consumption), while its stable power supply prevents downtime of servers and data storage devices.

● Transportation hubs: Used in high-speed rail stations, subway systems, and ports, it supports the power needs of signal systems, traction power (for trains), and logistics equipment. Its resistance to temperature fluctuations and humidity ensures reliable operation in outdoor or semi-outdoor installations.

IV. Special Harsh Environments

Its robust sealed structure and corrosion resistance make it suitable for challenging conditions:

● Mining & oilfields: In underground mines or remote oilfields, where environments are humid, dusty, or exposed to corrosive substances, the transformer’s insulation oil and sealed tank protect internal components from damage, ensuring power supply for mining machinery or oil extraction equipment.

● Remote off-grid systems: For isolated areas (e.g., mountainous villages, island communities) with independent power systems (powered by small hydropower or diesel generators), the transformer’s low maintenance requirements and long lifespan reduce the need for frequent on-site repairs, ensuring stable daily power.