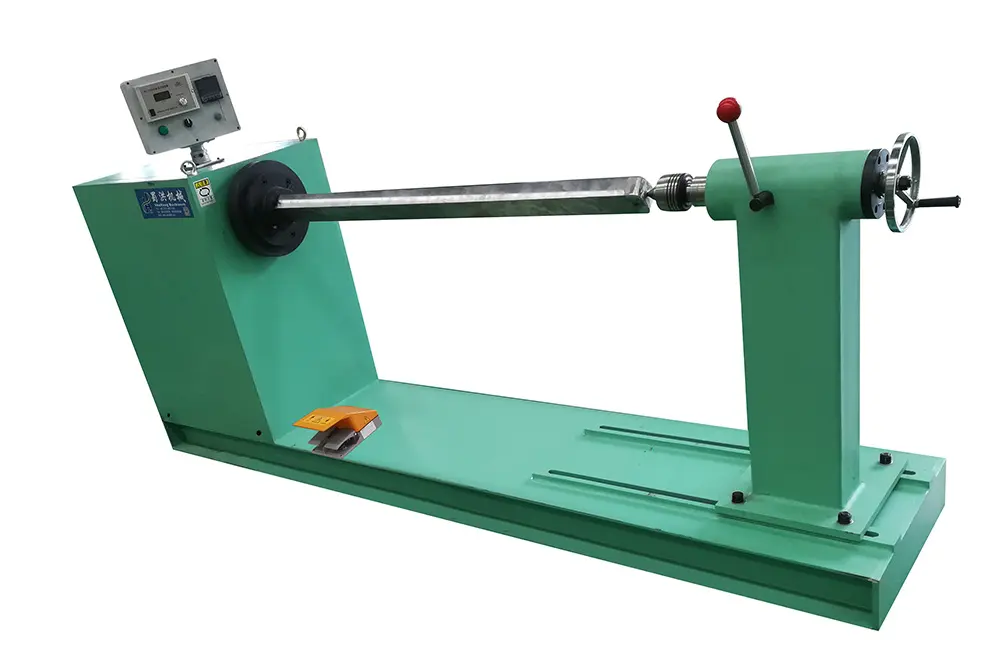

Precision Wire-Arranging High & Low Voltage Horizontal Winding Machine

Product Specification

| Code | SH-0.5T | SH-1T | SH-2T | SH-3T | SH-5T | SH-10T |

| Max. Loading | 0.5T | 1T | 2T | 3T | 5T | 10T |

| Main axis rotating speed | 0-240r/min | 0-150r/min | 0-90r/min | 0-60r/min | 0-20r/min | 0-10r/min |

| Speed adjusting method | Stepless speed adjust | |||||

| Main axis center height | 850mm | 850mm | 1000mm | 1100mm | 1300mm | 1400mm |

| Max. distance between main axis and end seat | 1200mm | 1500mm | 2000mm | 2500mm | 3000mm | 3500mm |

| End seat moving stroke | 0-600m | 0-750m | 0-1000m | 0-1200m | 0-1500m | 0-1500m |

| Main axis power | 3kw | 4kw | 5.5kw | 7.5kw | 11kw | 15kw |

Advantages

1. Strong Load-Bearing Stability of Horizontal Structure, Suitable for Heavy-Duty Coils: Adopting an integrated rigid base design for the headstock and tailstock, it has a load capacity of 1,000 kg to over 25 tons, enabling stable support for large-diameter (≤3,500 mm) and heavy high-voltage pancake coils or large low-voltage layer coils. Compared with vertical winding machines, the horizontal layout distributes the coil’s gravity, avoiding radial runout (runout ≤0.1 mm) caused by center-of-gravity deviation during winding—ideal for precision winding of heavy workpieces like transformer high-voltage coils. It is also equipped with an electromagnetic brake device to quickly lock the spindle during shutdown and prevent coil loosening due to reverse rotation.

2. Full Compatibility with Both High and Low Voltages, Adapting to Multi-Specification Wires & Coils: It covers the winding needs of low-voltage coils (≤10 kV) and high-voltage coils (110 kV–500 kV), and is compatible with various wire types such as round wires (0.3 mm–3 mm diameter), flat wires (≤3×12 mm cross-section), and transposed conductors. Through a modular tension adjustment system (adjustable 5–5,000 N), it applies micro-tension control to thin low-voltage wires (e.g., 0.3 mm enameled wires) to avoid breakage, and increases tension for thick high-voltage wires (e.g., 12 mm paper-insulated flat wires) to ensure tightness. No equipment replacement is required to meet the production needs of multiple transformer types (distribution, power, dry-type transformers).

3. High-Precision Wire Arrangement & Forming, Ensuring Coil Electrical Performance: Equipped with a wire arrangement mechanism driven by a servo motor, ball screw, and linear guide, the wire arrangement precision reaches 0.01 mm level, enabling tight and uniform turn-to-turn wire arrangement (gap ≤0.1 mm) and effectively reducing coil eddy current loss. Combined with a PLC-controlled turn counter (maximum setting 99,999.9 turns, error ≤±1 turn), it accurately controls the number of coil turns and avoids transformer voltage ratio deviation caused by winding errors. Some models are also equipped with a radial pneumatic pressing device to further improve the radial tightness of the coil and reduce the risk of partial discharge during operation.

4. Efficient Automated Linkage, Reducing Labor Costs: Adopting a "touchscreen HMI + PLC control system," it supports preset storage of over 30 sets of process parameters (e.g., wire arrangement pitch, winding speed), eliminating the need for repeated debugging when switching coil specifications. It can link with high-low voltage tension pay-off stands, insulating paper winding machines, and other equipment via RS485 interface to realize integrated production of "pay-off – winding – insulation wrapping," with production efficiency increased by more than 5 times compared to manual winding. The variable frequency speed regulation system (0–60 r/min stepless adjustment) automatically matches the winding speed according to wire specifications, and the start/stop slope can be preset to avoid wire damage caused by impact.

5. Flexible Process Adaptability, Covering Mainstream Winding Needs: It is perfectly adapted to core transformer coil processes: during layer winding, the wire arrangement mechanism operates synchronously with the spindle to ensure parallel wire arrangement between layers; during pancake winding, it can cooperate with a spacer adding mechanism to achieve spiral forming, solving the problem of easy spacer slipping in vertical winding machines. It supports 2–4 wire parallel winding processes, and ensures balanced force on multiple wires through independent tension control, meeting the low-loss winding needs of low-voltage coils for large transformers.

6. Stable & Safe Operation, Ensuring Consistency in Mass Production: Adopting a hard-tooth surface gear transmission system, it operates with noise ≤70 dB and transmission efficiency over 95%. Built-in functions such as tension deviation alarm (automatic shutdown when deviation >±3%), wire breakage detection, and overload protection can block faults in real time to prevent unqualified coils from entering subsequent processes, reducing the rejection rate to below 0.5%. Equipment parameters can be synchronized and stored via the network, enabling unified management of production data for multiple devices and ensuring performance consistency of mass-produced transformer coils.

Product Display

Application

I. Winding of Power Transformer Coils (Core Scenario)

● High-voltage coils (110 kV–500 kV): Suitable for high-voltage pancake coils of large power transformers (capacity ≥1000 kVA). Relying on the horizontal structure’s load capacity of 1000 kg–25 tons, it stably supports heavy coils with a diameter of ≤3500 mm. It cooperates with a spacer adding mechanism to realize spiral pancake winding, solving the problem of spacer slipping in vertical machines. Meanwhile, 5–5000 N tension control ensures the tightness of thick flat wires (e.g., 3×12 mm paper-insulated flat wires) during winding, reducing the risk of partial discharge.

● Large-capacity low-voltage coils (≤10 kV): Used for layer coils of low-voltage power transformers (capacity ≥315 kVA). Its 0.01 mm-level wire arrangement precision ensures the turn-to-turn gap of wires is ≤0.1 mm, reducing eddy current loss. It supports 2–4 wires for parallel winding, meeting the design requirements of low-loss coils.

II. Winding of Low-Voltage Distribution Transformer Coils (Mainstream Scenario)

For 10 kV/0.4 kV distribution transformers (capacity 10 kVA–1600 kVA), it is suitable for their low-voltage layer coils and small high-voltage pancake coils:

● Compatible with 0.3–3 mm enameled round wires and 1×3 mm flat wires. It can quickly switch between production of coils of different specifications (e.g., 100 kVA, 250 kVA models) by presetting over 30 sets of process parameters.

● Linked with low-voltage tension pay-off stands to realize synchronized "pay-off – winding", with mass production efficiency 5x higher than manual winding. The turn count error is ≤±1 turn, meeting the voltage ratio precision requirements of distribution transformers.

III. Winding of Dry-Type Transformer (Epoxy-Cast) Coils

Suitable for epoxy-cast coils of SCB-series dry-type transformers (10 kV–35 kV), solving the key problem of "wire arrangement regularity affecting casting quality":

● The radial pneumatic pressing device ensures the radial tightness of coils, avoiding air bubbles during casting.

● The high-precision wire arrangement mechanism controls the wire spacing error to ≤0.1 mm, ensuring the coil cross-section flatness (deviation ≤0.5 mm/m) – meeting the strict requirements of the epoxy casting process for coil forming. It is also compatible with winding of small-cross-section transposed conductors, adapting to the low-loss design of dry-type transformers.

IV. Winding of Special Transformer Coils

● Rectifier transformers: Used for multi-winding coils of industrial rectification equipment (e.g., for electrolysis, electroplating). It supports segmented winding of wires of different specifications (e.g., 0.5 mm round wires, 2×5 mm flat wires). Independent tension control avoids wire interference between multiple windings.

● Traction transformers (for high-speed rail/subway): Suitable for dense flat-wire coils on the low-voltage side of such transformers. The horizontal structure distributes the coil’s gravity to prevent iron core deformation during winding. Cooperated with variable frequency speed regulation (0–60 r/min), it realizes low-speed precision winding of flat wires, ensuring the fit between coils and iron cores.