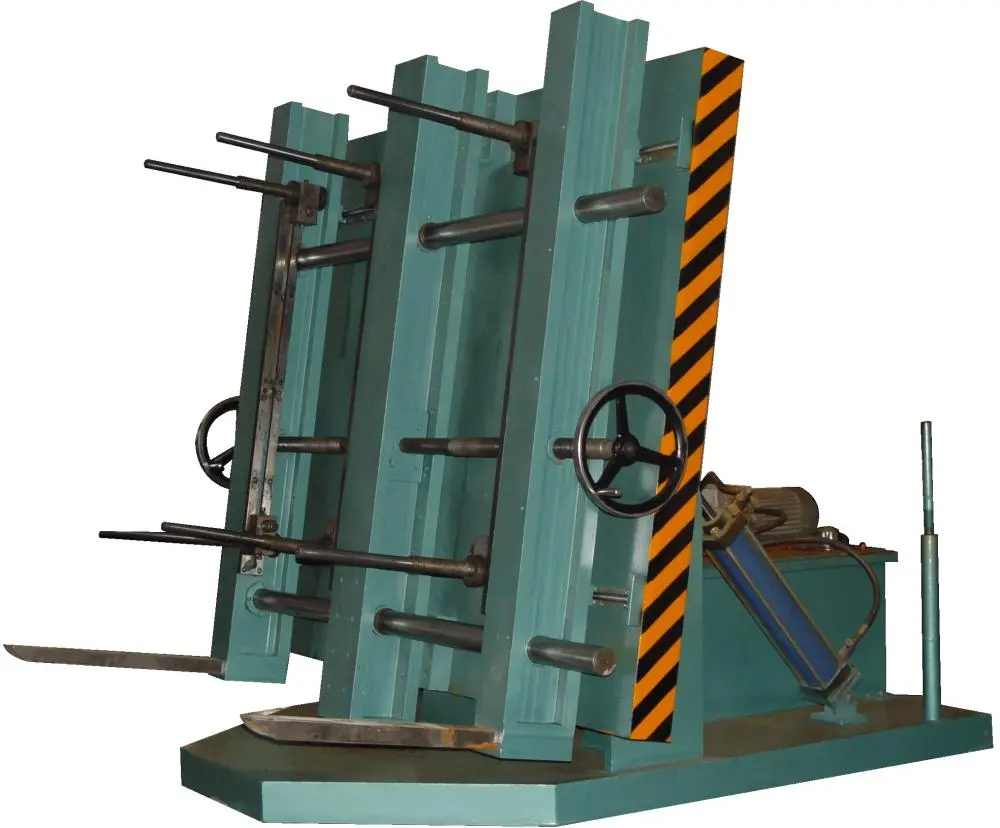

Silicon Steel Core Turning Table for Transformer Cores

Product Specification

|

Code |

SH-3T |

SH-5T |

SH-10T |

|

Loading |

3T |

5T |

10T |

|

Working heigh |

850mm |

1000mm |

1200mm |

|

Lron core size |

Length: 1500mm

Width: 1500mm |

Length: 2000mm

Width: 2000mm |

Length: 2500mm

Width: 2500mm |

|

Overturning angle |

0-90° |

0-90° |

0-90° |

Advantages

1,Stable Load-Bearing & Smooth Turning:Supports a maximum load of up to [XX] kg, enabling 0-180° continuous, low-vibration flipping. It avoids core displacement or deformation during turning (a common issue with manual handling), ensuring the structural integrity of silicon steel cores (e.g., transformer/motor cores) throughout the process.

2,High Post-Turning Positioning Accuracy:ProtectionGuarantees ±0.5mm positioning precision after flipping, ensuring the core remains aligned with subsequent assembly stations (e.g., lamination stacking, welding). This eliminates repositioning time and reduces assembly errors, directly improving production efficiency.

3,Effective Silicon Steel Core Protection:Equipped with anti-scratch padding on the work surface and adjustable clamping fixtures. It prevents scratches on the core’s surface and avoids excessive pressure-induced deformation—critical for maintaining the magnetic performance of silicon steel cores and reducing material waste.

4,Labor-Saving & Safe Operation:Replaces manual flipping of heavy cores (which is labor-intensive and high-risk), significantly reducing workers’ physical burden and lowering the risk of workplace injuries. Its automated/ semi-automated control simplifies operation, making it easy to integrate into existing production lines.

Product Display

Application

1. Transformer Core Manufacturing

It is widely used in the production of power transformers, distribution transformers, and special transformers. After silicon steel sheets are stacked into transformer cores (single-phase or three-phase), the table realizes smooth 0-180° flipping of the core. This facilitates subsequent processes such as winding (winding installation), core bonding, or end face trimming, while ensuring the core remains free of displacement—critical for maintaining the concentricity of the transformer’s magnetic circuit and reducing no-load loss.

2. Motor Core Production

For manufacturing high-frequency amorphous inductors (e.g., in new energy vehicle power systems) and amorphous power reactors (e.g., for power factor correction), the table assembles amorphous core bodies into stable structures. Its scratch-resistant design protects fragile amorphous materials, ensuring the inductors/reactors maintain stable electromagnetic characteristics during long-term operation.

3. Silicon Steel Core Inspection & Repair

In the quality inspection and repair links of silicon steel cores, the table provides stable positioning and flipping functions. Inspectors can use it to slowly flip the core to check for surface scratches, lamination looseness, or dimensional deviations on all sides; during repair, the table fixes the core in a suitable angle, allowing precise correction of defective parts (e.g., re-stacking loose laminations). This ensures the core meets quality standards before entering the next production process.