Specialized CNC Cross-Cutting Line for Silicon Steel Sheets

Product Specification

Code |

SH-300 |

SH-400 |

SH-600 |

SH-900 |

Shearing width |

40-300mm |

40-440mm |

60-640mm |

90-920mm |

Shearing length |

300-2000mm |

300-2500mm |

400-3500mm |

500-5000mm |

Shearing thickness |

0.20-0.35mm |

|||

Shearing length precision |

±0.1mm |

|||

Slitting burr |

≤0.02mm |

|||

Shearing angle precision |

±0.025° |

|||

Slitting width error |

±0.025° |

|||

Slitting burr |

≤0.02mm |

|||

Max feeding speed |

250m/min |

200m/min |

||

Sorting out method |

Automatic sorting out |

|||

Hold punching diameter |

According to requirement |

|||

Locating method |

Center locating |

|||

Installing capacity |

25kw |

30kw |

35kw |

70kw |

Advantages

1. High Cutting Precision: Adopts advanced CNC control system. achieving a cutting accuracy of ±0.1mm. It ensures the flatness and dimensional consistency of silicon steel sheets (GO/NGO). laying a solid foundation for the performance stability of downstream motor/transformer cores.

2. Efficient Production: Features high-speed cutting operation and integrated automatic feeding. positioning. and stacking. It reduces manual intervention. cuts down material waste. and improves overall production efficiency by over 30% compared to traditional cutting equipment.

3. Strong Adaptability: Is specially optimized for silicon steel sheets (both grain-oriented and non-oriented types). It can flexibly adjust cutting parameters to meet diverse size requirements in electrical appliance. motor. and transformer manufacturing industries.

4. Compliant & Reliable: Meets international standards such as IEC and ASTM. The stable mechanical structure and intelligent fault early-warning function reduce equipment downtime. ensuring long-term reliable operation in industrial environments.

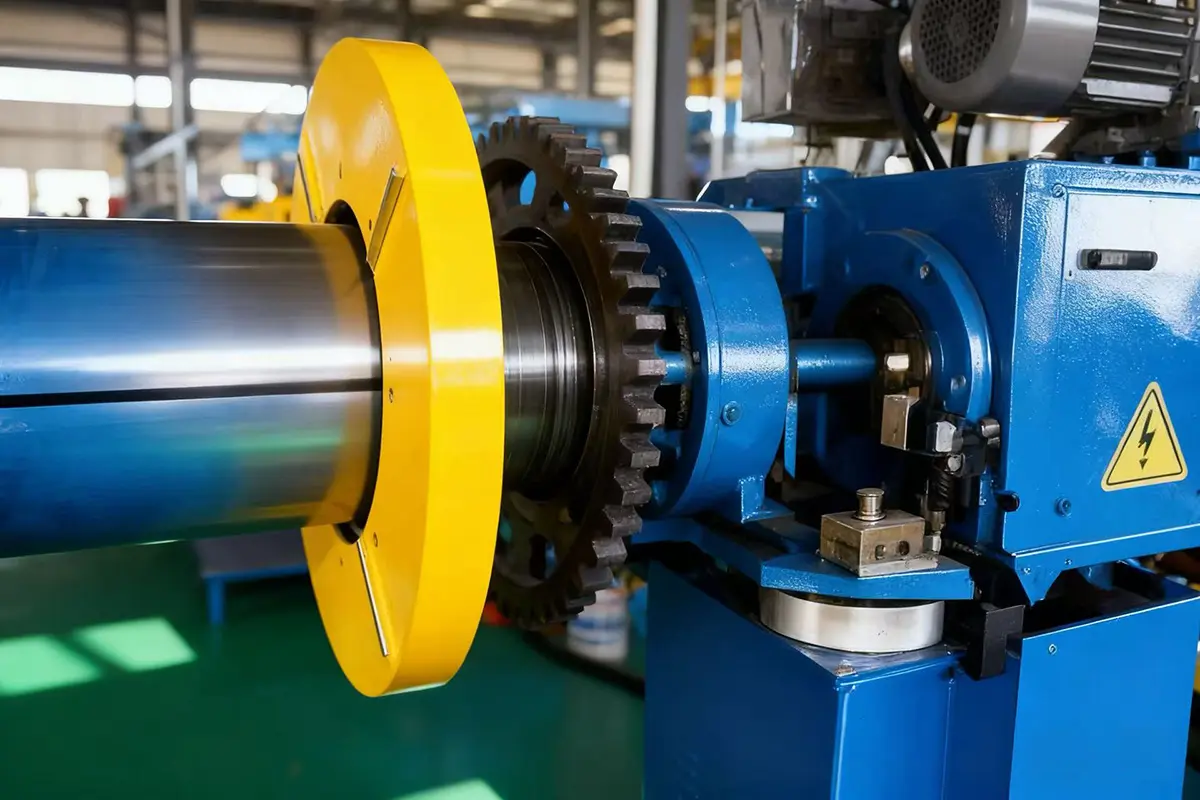

Product Display

Application

1. Motor Manufacturing Industry

It is used for cutting silicon steel sheets (both GO and NGO types) into stator and rotor core laminations—core components of motors. Whether for small and medium-sized motors (e.g., household appliance motors) or large industrial motors (e.g., new energy vehicle drive motors), the line’s high precision (±0.1mm) ensures the tight fit of laminations, reducing magnetic loss and improving motor energy efficiency and operational stability.

2. Transformer Manufacturing Industry

It processes silicon steel sheets into transformer core laminations (such as step-lap or straight-lap structures) for power transformers, distribution transformers, and special transformers (e.g., dry-type transformers). The line’s stable cutting quality and low material waste rate help reduce transformer core loss, meeting the energy-saving requirements of modern power grids for low-loss transformers.

3. Electrical Equipment & Appliance Industry

● It supplies precision-cut silicon steel sheets for manufacturing power inductors, reactor cores, and welding machine cores, ensuring the electromagnetic performance of these devices.

● For household electrical appliances (e.g., air conditioner compressors, washing machine motors), it cuts small-sized, high-precision silicon steel sheet blanks, matching the miniaturization and high-efficiency trends of home appliance components.