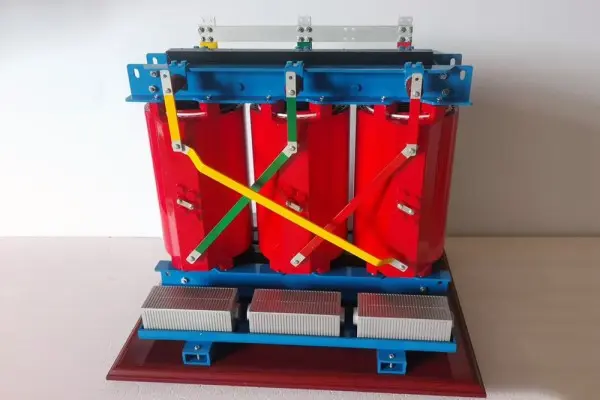

Top Transformer Coil Winding Machines from Leading Factories for Maximum Efficiency

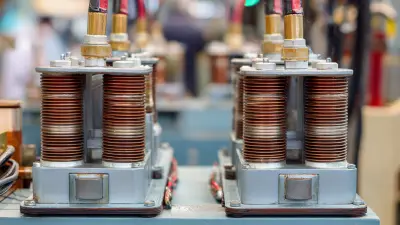

The Transformer Coil Winding Machine I utilize has significantly streamlined my coil winding process. Its design prioritizes efficiency and precision, ensuring uniformity in every winding. This machine, produced by WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., is a standout choice for manufacturers needing high-quality results. With exceptional engineering and customer support, it easily adapts to any production environment, whether for small workshops or large-scale facilities. Additionally, it accommodates a wide range of transformer designs, enhancing productivity and flexibility in operations. In my experience, WUXI SHUHONG consistently provides machines that surpass expectations, making this product a vital asset for anyone serious about optimizing their coil winding capabilities.

Key Methods For Transformer Coil Winding Machine Supplies the World’s Top Brands Factory

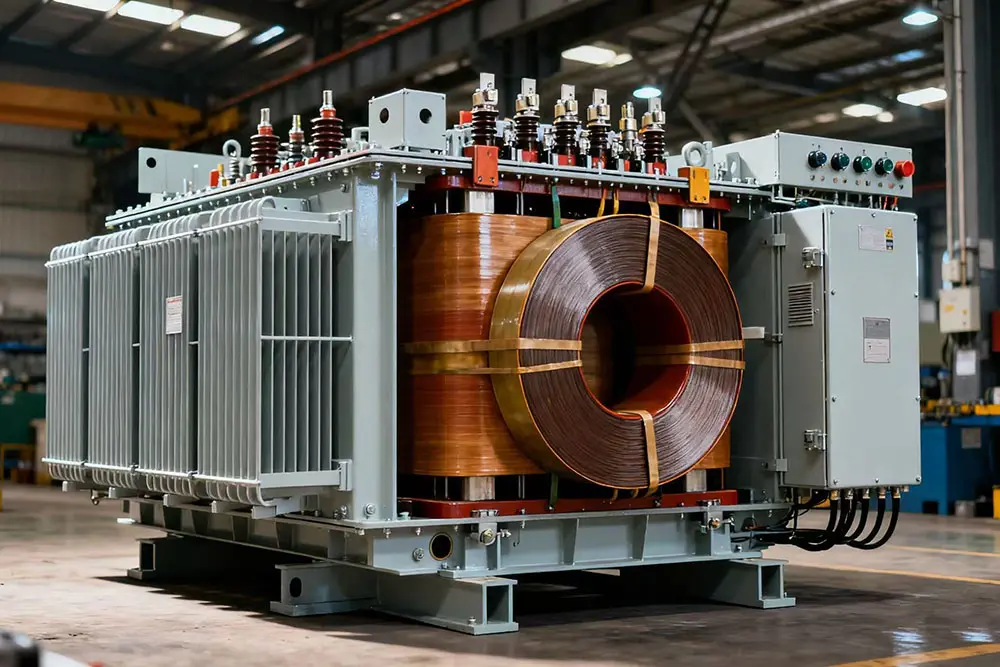

In today's competitive landscape, the demand for high-quality transformer coil winding machines is surging, particularly among top brands seeking to enhance their manufacturing capabilities. One of the key methods for ensuring optimal performance in these machines lies in the integration of cutting-edge technology and robust engineering. Emphasizing precision winding techniques, advanced control systems, and user-friendly interfaces can significantly increase productivity and decrease downtime, ultimately leading to a more efficient manufacturing process.

Moreover, sourcing these machines from reputable suppliers can make a considerable difference. Quality assurance, after-sales support, and long-term reliability are factors that procurement professionals should prioritize. A deep understanding of material compatibility, winding configurations, and process automation can empower manufacturers to choose the right machines that meet their unique production needs. These considerations are vital in fostering innovation and ensuring the longevity of the equipment, which is crucial for maintaining competitive advantage in the evolving energy sector.

In conclusion, as global procurement professionals search for the best transformer coil winding machines, a focus on technological innovation, quality assurance, and supplier reputation will be paramount. By investing in state-of-the-art machinery that aligns with their operational goals, manufacturers not only optimize their production processes but also contribute to a sustainable energy future.

Key Methods For Transformer Coil Winding Machine Supplies the World’s Top Brands Factory

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Automatic Winding | Utilizes automated systems to wind coils with precision. | High efficiency, reduced labor costs, consistent quality. | Power transformers, inductors, and motor coils. |

| Manual Winding | Coils are wound by operators using hand tools and devices. | Flexibility in design, suitable for small production runs. | Custom coils and prototypes. |

| Toroidal Winding | Winding process for toroidal transformers using specialized tools. | Compact design, improved efficiency, lower electromagnetic interference. | Audio transformers, power transformers. |

| Multi-layer Winding | Creates coils with multiple wire layers for higher capacity. | Enhanced electrical performance, efficient use of space. | High power applications, industrial transformers. |

| High-speed Winding | Utilizes fast winding techniques to increase production speed. | Increased output, reduced cycle time. | Large-scale transformer production. |

How To Pick The Right Transformer Coil Winding Machine Your End-to-End Solution Market Leader

C

Charlotte Allen

I’m really pleased with the quality of this product. Plus, the support team was professional and efficient in handling my inquiries.

14

September

2025

W

William Taylor

I’m blown away by the quality of this item. The after-sales support was also very professional, making the entire experience seamless.

12

September

2025

C

Chloe Young

I love this product! The quality is fantastic, and the support from the team was impeccable and very professional.

23

September

2025

J

Jackson Martinez

Superb quality! The after-sales service provided was exemplary, with very professional and friendly staff.

31

August

2025

M

Michael Smith

This purchase has been a game-changer for our operations. The quality is top-notch, and the after-sales personnel were incredibly knowledgeable and helpful.

25

August

2025

C

Christopher Martinez

Impressive quality all around. The customer support team really knows their stuff and went above and beyond to ensure I was happy with my purchase.

24

September

2025