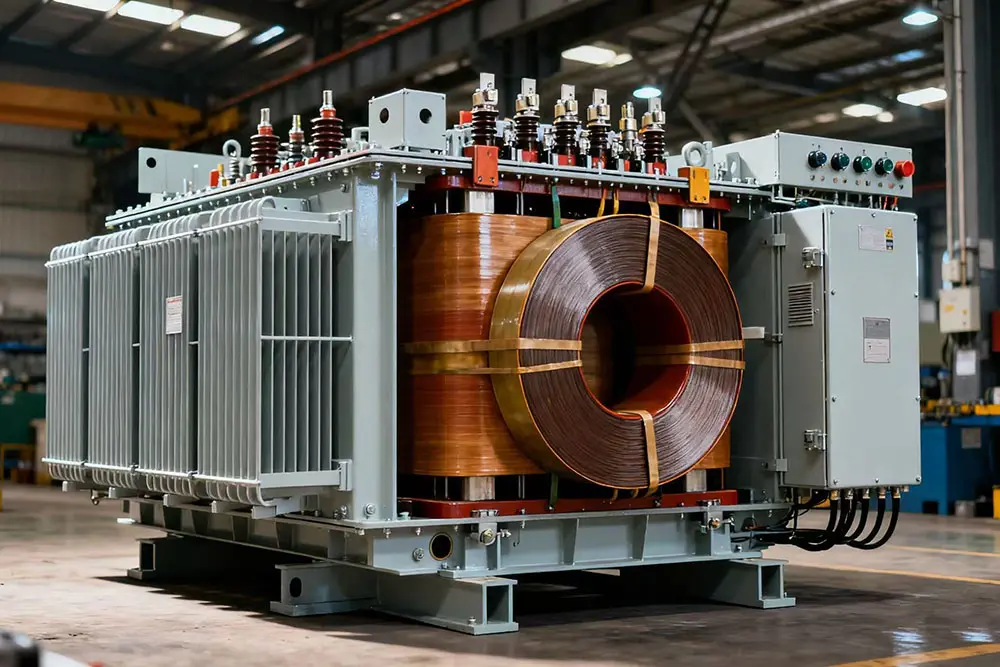

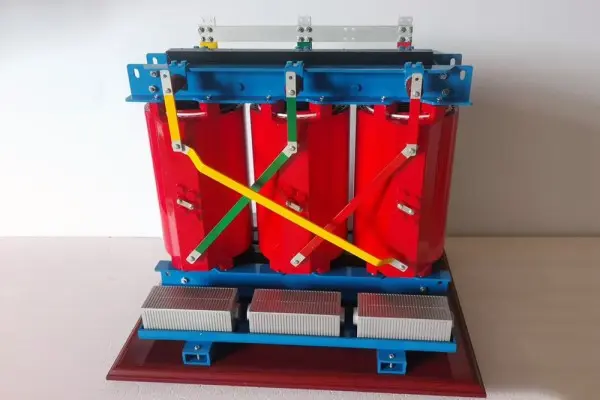

Top-Quality Custom Transformer Windings for Enhanced Performance and Reliability

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we prioritize quality and reliability in transformer winding solutions. Our products are designed to be cost-effective without compromising performance. Crafted with precision, our transformers ensure durability while remaining budget-friendly. Backed by advanced technology and skilled craftsmanship, we deliver some of the most affordable options in the market. Whether you represent a small business or a large corporation, we are committed to providing transformer windings that align with your specifications and financial plans. Partnering with us means choosing a manufacturer dedicated to your success, offering reliable products that endure over time.

10 Essential Tips For Transformer Winding Outperforms the Competition Your End-to-End Solution

In the competitive landscape of transformer winding, achieving excellence requires not only technical expertise but also a holistic approach to solutions. Here are ten essential tips to help elevate your winding processes and outperform the competition.

Firstly, invest in advanced machinery that incorporates the latest technologies. This will not only enhance the precision of your windings but also improve efficiency. Regularly upgrading equipment ensures you stay ahead of industry standards. Secondly, adopt a rigorous quality control protocol throughout the winding process. Implementing checkpoints can help identify issues early on, saving time and resources.

Next, train your workforce continually. Skilled operators are vital for ensuring that machinery runs optimally and that winding procedures are correctly followed. Additionally, collaborating with suppliers who understand your needs can lead to better material quality and sourcing timelines. Finally, harness data analytics to monitor production metrics and identify areas for improvement. By implementing these strategies, you can position your business as a leader in transformer winding, ready to meet the demands of a rapidly evolving energy sector.

10 Essential Tips For Transformer Winding Outperforms the Competition Your End-to-End Solution

| Tip Number | Tip Description | Expected Outcome | Implementation Time |

|---|---|---|---|

| 1 | Optimize winding design to reduce losses | Increased efficiency and performance | 1 month |

| 2 | Use high-quality insulating materials | Enhanced durability and reliability | 2 weeks |

| 3 | Implement automated winding processes | Consistent quality and reduced labor costs | 3 months |

| 4 | Regular maintenance of winding equipment | Minimized downtime | Ongoing |

| 5 | Conduct thermal and electrical testing | Ensure compliance and reliability | 1 month |

| 6 | Use advanced simulation tools | Improved design accuracy | 2 months |

| 7 | Train staff on winding technologies | Enhanced skillset and efficiency | Ongoing |

| 8 | Implement quality control measures | Consistent product quality | 1 month |

| 9 | Review and optimize supply chain | Reduced costs and improved delivery | 2 months |

| 10 | Stay updated with industry trends | Innovative solutions and market relevance | Ongoing |

How To Identify Transformer Winding Winning in 2025 From Concept to Delivery

J

Jackson Hall

Incredible quality! Their after-sales service was remarkable, with staff who truly know how to support their customers.

14

August

2025

Z

Zoe Cooper

Absolutely love this product! The quality is fantastic and the after-sales service staff were incredibly professional.

06

September

2025

V

Victoria Johnson

Incredible product quality! The professionalism and dedication of the after-sales team left a positive impression.

25

September

2025

H

Hannah Wright

Truly a fantastic product! The quality is outstanding, and the after-sales team went above and beyond with their support.

20

August

2025

L

Logan Lewis

I highly recommend this product. The quality is impressive, and the support staff were incredibly professional and attentive.

31

August

2025

J

James Anderson

I am thoroughly impressed with the quality of the product. The attention to detail is remarkable, and the after-sales support was exceptional. Highly recommend!

27

September

2025