Top Transformer Winding Insulation from Premier Manufacturer for Optimal Performance

Every penny matters, and that's why we offer appealing discounts to enhance your purchasing experience. Our products undergo rigorous testing to ensure they meet high industry standards and cater to your specific needs. For any inquiries about our products or available discounts, feel free to reach out. Your satisfaction is my priority, and I’m here to help you make well-informed choices for your business.

Ultimate Guide To Transformer Winding Insulation Where Service Meets Innovation Application

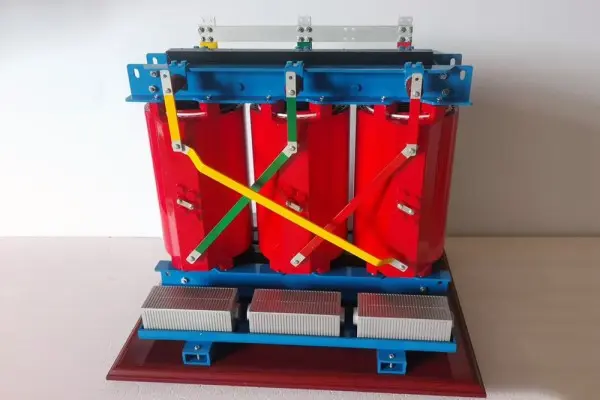

In the evolving landscape of the machinery industry, the importance of transformer winding insulation cannot be overstated. As renewable energy sources gain traction and electrical machinery becomes more integral to various applications, the need for reliable and innovative insulation solutions is paramount. This guide delves into the critical aspects of transformer winding insulation, highlighting its significance in enhancing operational efficiency and extending the lifespan of electrical components.

Transformer winding insulation serves as a protective barrier against electrical faults, moisture, and thermal stress, ensuring optimal functionality under demanding conditions. The materials and technologies employed in insulation have advanced significantly, driven by the necessity for higher durability and performance standards. Employing innovative materials not only mitigates risks associated with overheating and short circuits but also contributes to the overall reliability of energy systems that power our future.

As global procurement professionals seek to optimize their supply chains, understanding the intricacies of transformer winding insulation is essential. Leveraging cutting-edge technology in this area can lead to increased energy efficiency, reduced maintenance costs, and improved safety measures. In a market where innovation meets service, the commitment to excellence in insulation solutions will empower businesses to thrive and adapt in an ever-changing energy landscape.

Ultimate Guide To Transformer Winding Insulation Where Service Meets Innovation Application

| Parameter | Description | Importance | Common Materials | Latest Innovations |

|---|---|---|---|---|

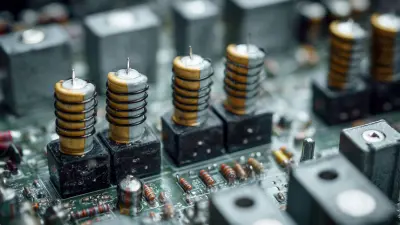

| Dielectric Strength | Ability of insulation to withstand electric stress without breakdown. | Critical for preventing electrical failure in transformers. | Paper, resin, epoxy | Nanofiber technology for improved performance. |

| Thermal Stability | Resistance of the insulation to heat deterioration. | Ensures longevity and reliability under operating conditions. | Silicone, polyester films | Self-healing insulation materials. |

| Moisture Resistance | Ability of insulation to deter moisture ingress. | Prevents corrosion and degradation of winding materials. | Composite materials, varnishes | Hydrophobic coatings enhancing water resistance. |

| Mechanical Strength | Ability to withstand physical stress without damage. | Important for durability in demanding applications. | Fiberglass, bonded materials | Use of advanced composites for higher strength. |

| Electrical Conductivity | Measure of how easily electric charge passes through the material. | Critical for efficiency and performance in transformer operation. | Copper, aluminum foils | Conductive polymers for enhanced efficiency. |

Where the Value Lies Transformer Winding Insulation Stands Out Where Innovation Meets 2025

R

Rachel Adams

The product quality speaks for itself. Coupled with fantastic after-sales service, it has made my purchase satisfying beyond measure.

31

August

2025

W

William Green

I received a fantastic product. The customer service was very responsive and the team demonstrated a high level of professionalism.

01

September

2025

E

Ethan Clark

This product is of exceptional quality. The customer service staff were very professional and resolved my concerns efficiently.

24

August

2025

J

Jackson Hall

Incredible quality! Their after-sales service was remarkable, with staff who truly know how to support their customers.

14

August

2025

J

Jameson Lee

Very high-quality product! The after-sales support provided by their professionals was outstanding and very reassuring.

13

September

2025

E

Emily Johnson

Fantastic purchase! The quality is evident, and I appreciated the professional demeanor of the customer service team when I needed follow-up information.

03

September

2025