Automatic Transformer Winding Machines from Leading Factory Manufacturers - Best Quality

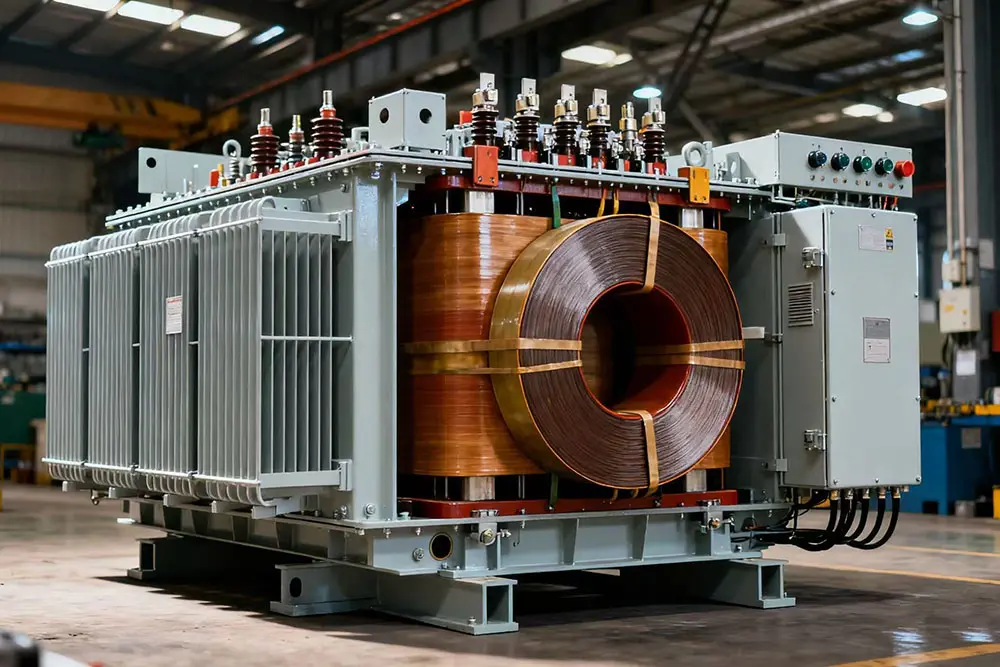

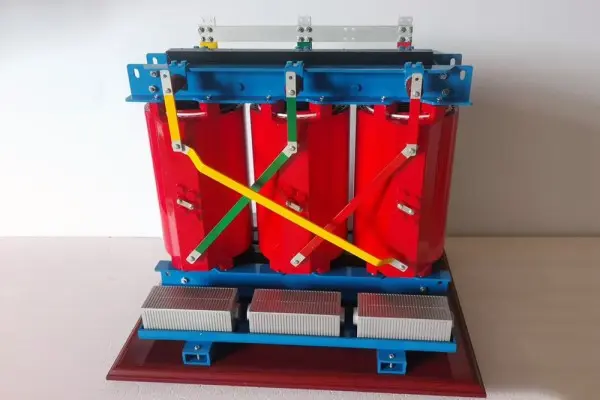

Enhance your transformer production efficiency with our Automatic Transformer Winding Machine. This cutting-edge equipment streamlines the winding process while ensuring precision and effectiveness, making it an essential asset for any manufacturing line. At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., we prioritize quality and innovation in all our products. Our Transformer Winding Machine is engineered with advanced technology to meet the diverse needs of our clients. We recognize that choosing the right equipment is vital for your business success, which is why we provide customized solutions to fit your specific requirements. Partner with us to achieve significant improvements in your operational efficiency at competitive prices. Join our growing list of satisfied customers who trust us as their dependable manufacturer. Elevate your production capabilities with our expertise!

7 Key Tips To Transformer Winding Machine Automatic Exceeds Industry Benchmarks Supplies the World’s Top Brands

In today's competitive manufacturing landscape, achieving operational excellence is paramount. For global procurement professionals seeking reliable suppliers of transformer winding machines, understanding key advancements in technology can help elevate their production capabilities beyond industry benchmarks. Here are seven essential tips to consider when evaluating automatic transformer winding machines.

First, prioritizing innovative features that enhance efficiency is crucial. Machines equipped with advanced automation technologies can optimize the winding process, reduce labor costs, and minimize human error. Additionally, look for offerings that support various winding techniques, allowing for versatile applications across different transformer designs.

Second, focus on manufacturers that emphasize quality assurance and rigorous testing procedures in their production processes. Machines that meet high industry standards not only perform better but are also more durable, translating to long-term savings. Finally, consider the supplier's commitment to after-sales support and service, which is vital for maintaining peak operational performance and ensuring minimal downtime. By carefully evaluating these aspects, procurement professionals can foster partnerships that lead to improved efficiency and substantial growth in their production capabilities.

7 Key Tips To Transformer Winding Machine Automatic Exceeds Industry Benchmarks Supplies the World’s Top Brands

| Tip | Description | Expected Outcome | Industry Benchmark |

|---|---|---|---|

| 1. Enhance Automation | Implement advanced robotics for winding processes. | Increased efficiency and reduced manual errors. | 85% Automation Rate |

| 2. Optimize Materials | Use high-quality insulating materials for winding. | Improved durability and performance. | Minimum 10 Years Lifespan |

| 3. Implement Quality Control | Regular checks during the winding process. | Reduction of defects and waste. | Less than 1% Defect Rate |

| 4. Train Workforce | Continuous training and skill development programs. | Higher productivity and innovation. | 80% Skill Level Improvement |

| 5. Upgrade Equipment | Invest in state-of-the-art winding machines. | Faster production rates and reduced errors. | 30% Increase in Production Speed |

| 6. Utilize Data Analytics | Analyze machine performance data for insights. | Enhanced decision-making and operational efficiency. | 20% Improvement in Operational Efficiency |

| 7. Sustainable Practices | Adopt eco-friendly practices in production. | Reduced environmental impact and better brand reputation. | Lower Carbon Footprint by 15% |

10 tips Transformer Winding Machine Automatic Winning in 2025 Where Service Meets Innovation

M

Michael Thompson

I am genuinely impressed with the product quality. Additionally, the after-sales support from their team was exceptional and they really knew their stuff.

13

August

2025

H

Hannah Wright

Truly a fantastic product! The quality is outstanding, and the after-sales team went above and beyond with their support.

20

August

2025

S

Sofia King

This item is simply fantastic! Quality is unbeatable, and the support was incredibly helpful and professional.

16

August

2025

A

Aiden Hall

Outstanding quality! The post-purchase support provided was remarkably professional and efficient.

28

August

2025

L

Logan Lewis

I highly recommend this product. The quality is impressive, and the support staff were incredibly professional and attentive.

31

August

2025

L

Lily Perez

An impressive product! The quality is outstanding and the support team was top-notch in their professionalism.

09

September

2025