Vacuum Annealing Furnace for Metals/Silicon Steel

Product Specification

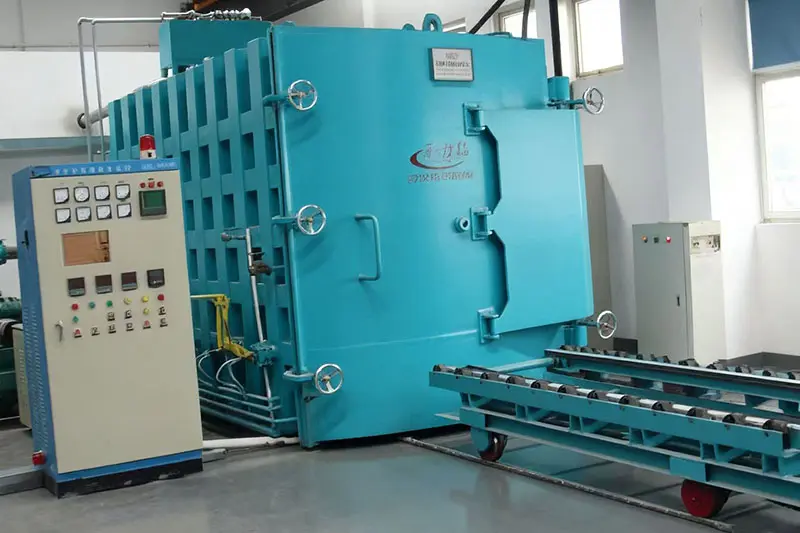

| Furnace type | Horizontal signal room |

| Effective size of inner liner | 1000x1100x2200mm (W)x(H)x(L) |

| Effective size of inner liner | 1200x1200x2600mm(W)x(H)x(L) Note: Rated furnace capacity 10000KG, Power 180KW, vacuum unit: 2X+70 pumps + 150 Roots pumps, other technical requirements are the same. |

| Max loading capacity | 5000kg |

| Maximum furnace temperature | 950℃ (900℃ (800℃-850℃ is enough for your material)) |

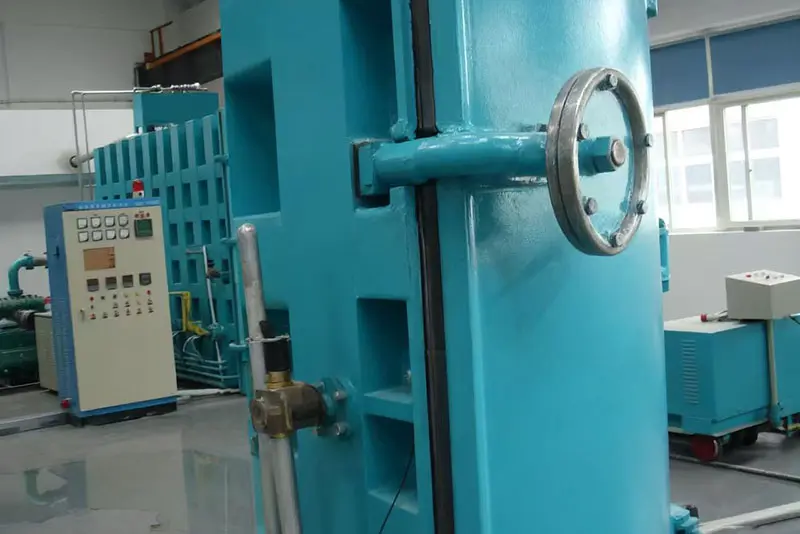

| Limit vacuity | 100Pa |

| Pressure rising rate | <50Pa/h |

| Air exhausting time | 30min(Vacuum 400Mpa) |

| Heating power | 120kW (3×40kW) |

| Temperature uniformity | ≤±2℃(Insulation) |

| Temperature of furnace surface | Room temperature+35℃ |

| Temperature Points | 3 |

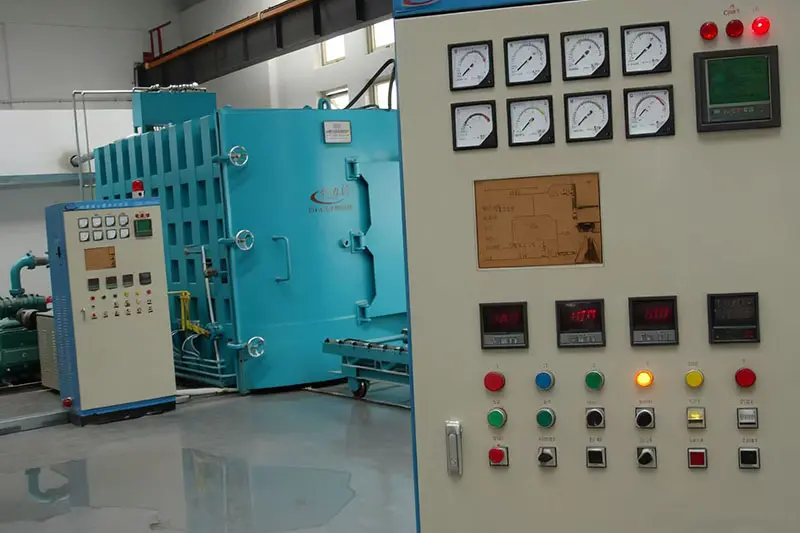

| Temperature control method | Automatic by program |

| Operation mode | Manual (Furnace door) |

| Cooling water capacity | (Tons per hour)10~12(T) |

Advantages

1. Oxidation & Contamination Prevention: Operates in a high-vacuum atmosphere, completely isolating materials (e.g., silicon steel, amorphous alloys) from air during annealing. This eliminates oxidation, decarburization, and impurity adsorption, ensuring the original purity and surface quality of materials—critical for high-performance components like silicon steel cores.

2. Precise Temperature Control: Offers a wide temperature range (RT-1200℃) with ±5℃ control accuracy. It enables precise tuning of annealing processes to target specific material improvements: relieving internal stress (reducing deformation in subsequent processing), enhancing toughness (extending component service life), and optimizing magnetic properties (boosting energy efficiency of magnetic materials).

3. Strong Material & Industry Adaptability: Suitable for heat treatment of diverse materials—metals (stainless steel, carbon steel), amorphous alloys, and magnetic materials. It meets annealing demands across sectors: electrical (silicon steel core processing), automotive (high-strength metal parts), and machinery (precision component stress relief), with flexible process parameter adjustment for different specs.

4. Efficient & Safe Operation: Integrates intelligent control systems for automated temperature ramping, vacuum monitoring, and batch processing—shortening annealing cycles by 20%+ vs. traditional furnaces. Equipped with overheating protection, vacuum leakage alarms, and pressure relief devices, it complies with industrial safety standards, ensuring stable, low-risk long-term operation.

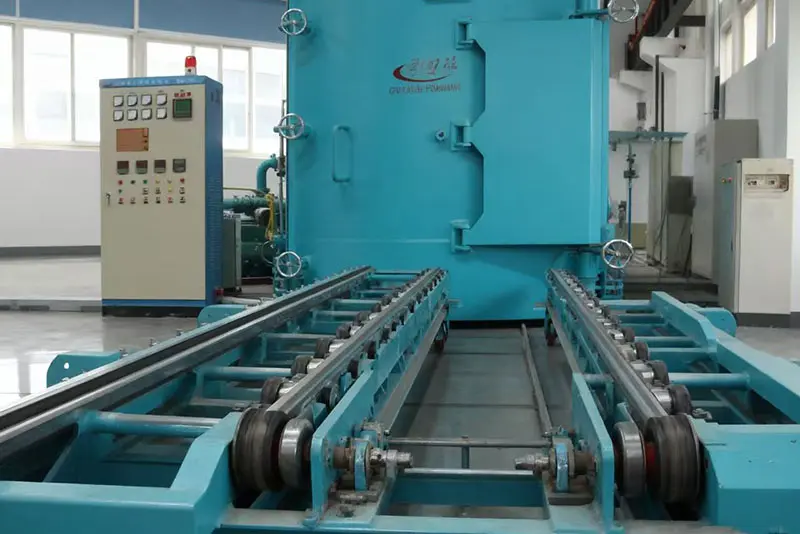

Product Display

Application

1. Silicon Steel & Magnetic Material Processing

It is essential for annealing grain-oriented (GO) and non-oriented (NGO) silicon steel cores (used in transformers and motors). Under vacuum, it eliminates oxidation, optimizes silicon steel’s grain orientation, and reduces internal stress—directly enhancing magnetic permeability and lowering core loss. This ensures the energy efficiency of final electrical products (e.g., low-loss transformers, high-performance motors) meets industrial standards.

2. Metal Component Manufacturing (Automotive & Machinery)

For high-strength metal parts (e.g., automotive transmission components, precision mechanical gears) and stainless steel products, the furnace performs vacuum annealing to relieve internal stress caused by forging, casting, or machining. This prevents deformation/cracking during subsequent processing or use, improves material toughness and fatigue resistance, and extends the service life of components—critical for automotive and heavy machinery reliability.

3. Amorphous Alloy & Special Material Treatment

It processes amorphous alloy cores (for amorphous transformers/inductors) and rare metal materials (e.g., titanium alloys). The vacuum environment avoids oxidation of fragile amorphous alloys during annealing, maintains their unique atomic structure, and stabilizes magnetic properties. For rare metals, it ensures surface purity, laying the foundation for their application in high-tech fields (e.g., aerospace precision parts).