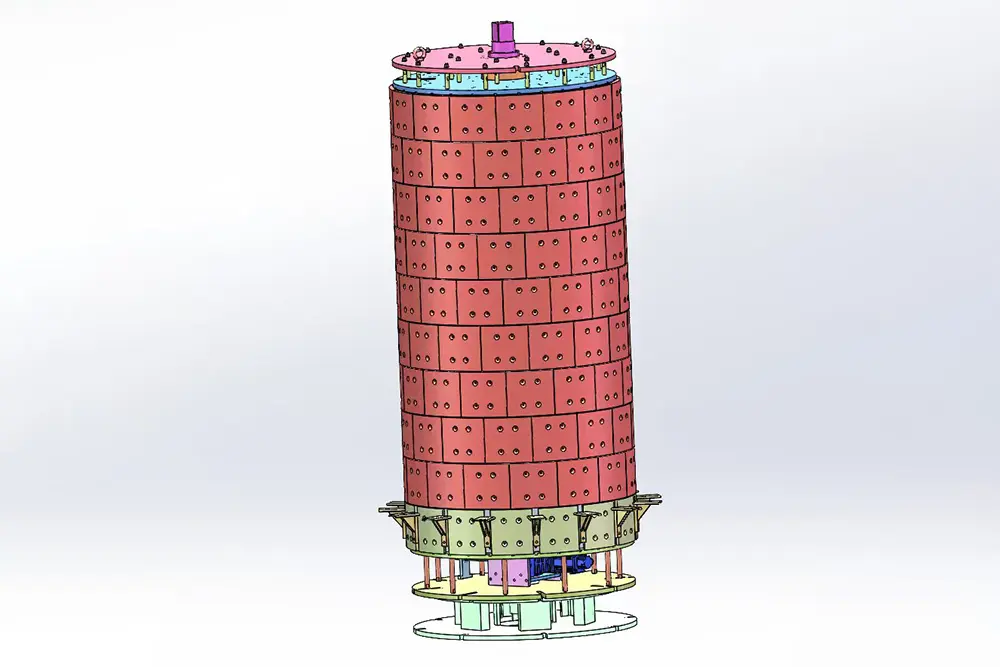

Vertical Winding Machine for Transformer Coil Manufacturing

Product Specification

Technical Parameters | |

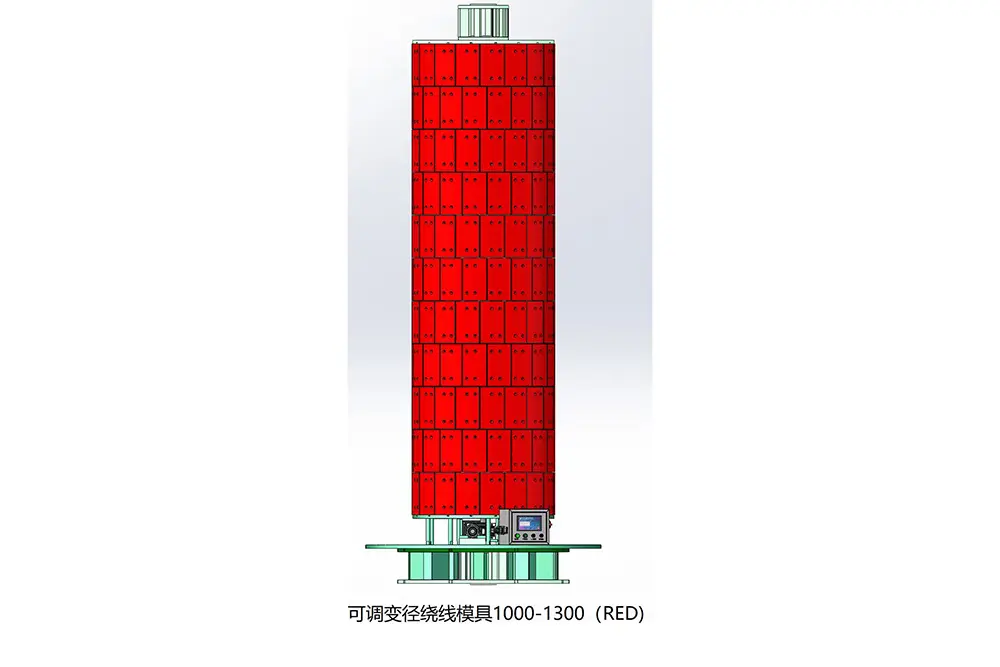

Max. Winding Diameter |

200-1200mm (Customizable) |

Winding Speed |

5-30r/min (Stepless Adjustable) |

Positioning Precision |

±0.05mm |

Adaptable Material |

|

Foil |

Copper Foil, Aluminum Foil (Thickness: 0.1-2.0mm) |

Wire |

Copper Wire, Aluminum Wire (Diameter: 0.5-5.0mm) |

Power Supply |

380V/220V 50/60Hz (Optional) |

Power Consumption |

≤5kW |

Machine Dimension |

2200×1500×2800mm (Approx.) |

Net Weight |

1800kg (Approx.) |

Control Mode |

Automatic/Manual Switchable |

Performance Features | |

Adopts vertical winding structure, ensuring high perpendicularity and compactness of transformer coils. | |

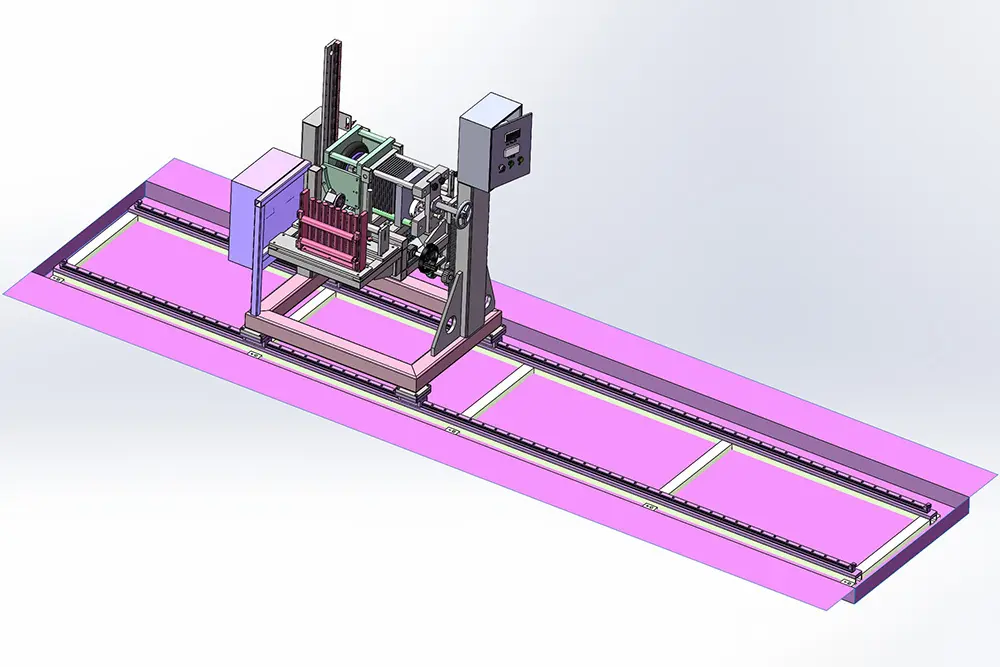

Equipped with high-precision servo control + PLC system, realizing accurate winding position control and stable operation. | |

Integrated automatic tension control system, preventing material deformation and ensuring uniform winding tightness. | |

Supports automatic wire arranging and end fixing, reducing manual intervention and improving production efficiency by 40%+. | |

Compatible with multiple coil specifications, with flexible parameter adjustment to meet diverse production needs. | |

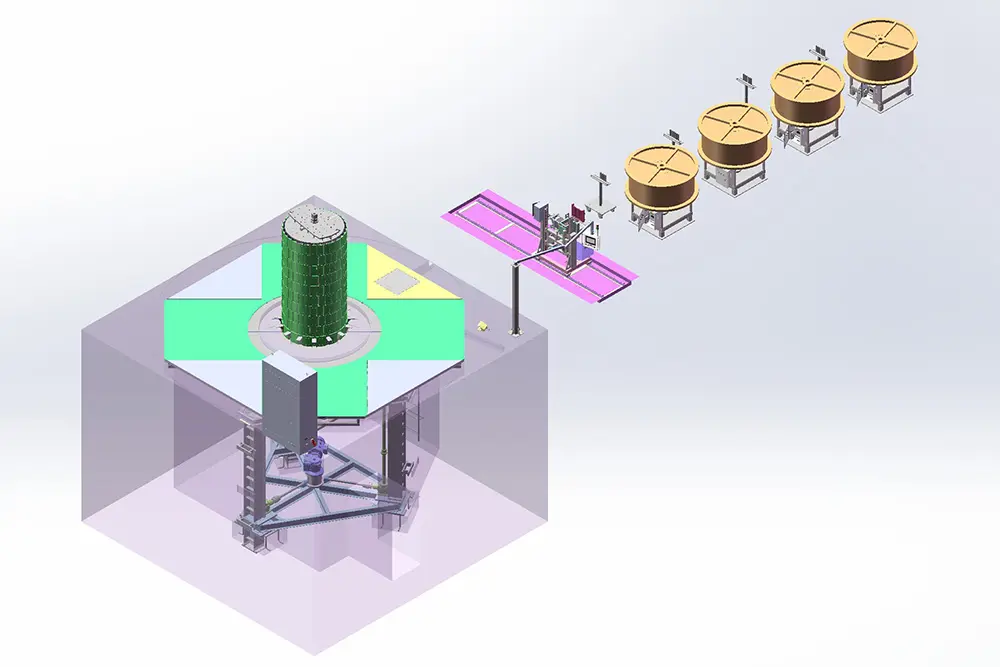

Structural Configuration | |

Main Body |

High-strength steel frame, treated with anti-rust coating for long service life. |

Control System |

PLC Controller + 10-inch Touch Screen HMI |

Driving System |

AC Servo Motor (Brand Optional:Siemens/Yaskawa) |

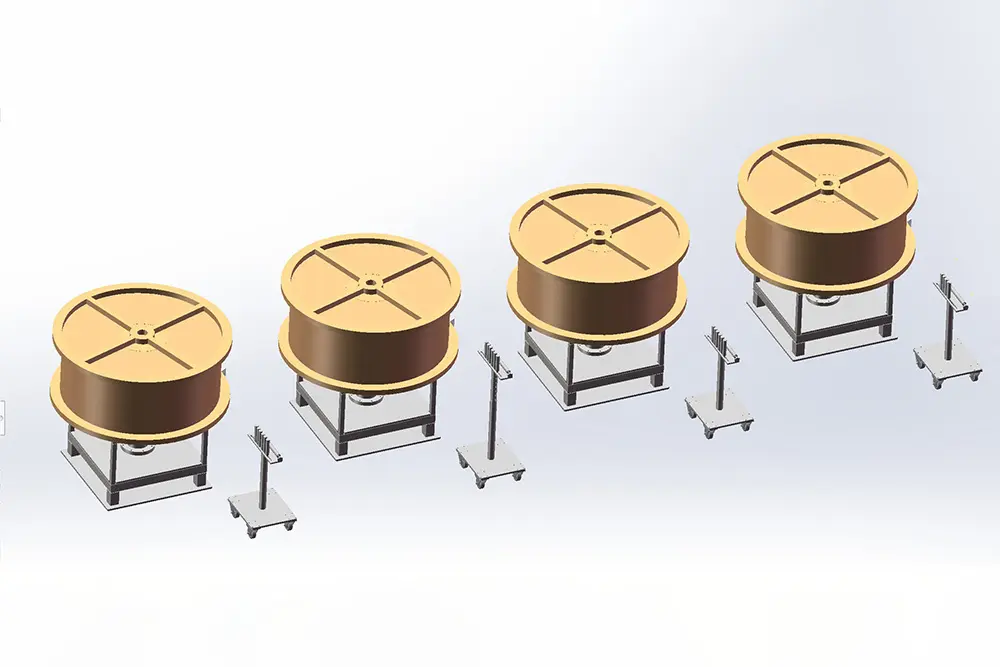

Tension System |

Automatic Tension Controller |

Wire Arranging Mechanism |

Precision Ball Screw Wire Arranger |

Applicable Scope | |

Transformer Type |

Power Transformer (10kV-220kV), Distribution Transformer (10kV 及以下), High-Frequency Transformer |

Coil Type |

Foil Winding Coil, Wire Winding Coil |

Applicable Material |

Copper Foil, Aluminum Foil, Enamelled Copper Wire, Enamelled Aluminum Wire |

Advantages

Superior Structural Performance

Adopts vertical winding structure, ensuring high perpendicularity and compactness of coils. Effectively avoids coil deformation caused by horizontal winding, enhancing the insulation and current-carrying stability of transformers.

High Precision & Stable Quality

Equipped with high-precision servo control + automatic tension system, achieving ±0.05mm positioning accuracy. Ensures uniform winding tightness and consistent coil dimensions, reducing material waste and improving product qualification rate.

High Efficiency & Labor Saving

Integrates automatic wire arranging, tension adjustment and end fixing functions. Reduces manual intervention by 60%+, shortens production cycle by 40%+ compared to traditional equipment, significantly boosting production efficiency.

Strong Adaptability

Compatible with copper/aluminum foil, enamelled wire and other materials, adapting to power, distribution and high-frequency transformer coils. Flexible parameter adjustment supports quick switching between different coil specifications.

Easy Operation & Maintenance

Adopts HMI touch screen with intuitive interface, enabling one-key parameter setting and operation. Modular design simplifies maintenance, reducing downtime and lowering post-use costs.

Product Display

Application

1. Core Application Positioning

As a core equipment for transformer coil manufacturing, the vertical winding machine is mainly used for the winding processing of coil conductors (foil/wire). Its vertical structure ensures the perpendicularity and compactness of coils, perfectly matching the production requirements of high-performance transformers, and is widely applied in power, distribution and high-frequency transformer production lines.

2. Application in Different Types of Transformer Coils

2.1 Power Transformer Coils

● Suitable for winding high-voltage, large-capacity power transformer coils (10kV-220kV). The vertical winding structure ensures uniform stress on the coil, avoiding deformation caused by gravity, and effectively improving the insulation performance and current-carrying stability of the coil.

● Cooperates with insulation paper winding mechanism to realize integrated winding of conductor and insulation layer, meeting the strict quality requirements of power transformers for coil compactness and dielectric strength.

2.2 Distribution Transformer Coils

● Applied in the mass production of medium and low voltage distribution transformer coils (10kV and below). It supports quick switching between different coil specifications, with high winding efficiency, adapting to the characteristics of multiple varieties and batch production of distribution transformers.

● The automatic wire arranging and tension control functions ensure consistent coil dimensions, reducing the difficulty of subsequent assembly and improving the overall production efficiency of distribution transformers.

2.3 High-Frequency Transformer Coils

● Used for winding fine coils of high-frequency transformers (such as switching power supply transformers). With high-precision positioning (±0.05mm), it ensures the uniformity of coil turns, reduces distributed capacitance and inductance loss, and guarantees high-frequency signal transmission efficiency.

● Adapts to thin foil (thickness ≤0.1mm) and fine wire (diameter ≤0.5mm) materials, meeting the miniaturization and high-precision requirements of high-frequency transformer coils.

3. Key Application Links in Production

● Conductor Winding: Realizes high-precision winding of copper/aluminum foil and enamelled wire, forming the main body of the transformer coil.

● Insulation Matching: Cooperates with automatic insulation material feeding to complete integrated winding of conductor and insulation layer, ensuring coil insulation performance.

● Coil Shaping Auxiliary: The vertical winding process ensures the coil's verticality and roundness, laying a foundation for subsequent processes such as drying and impregnation.