Winding Motors: Best Discounts from Leading Suppliers and Factories

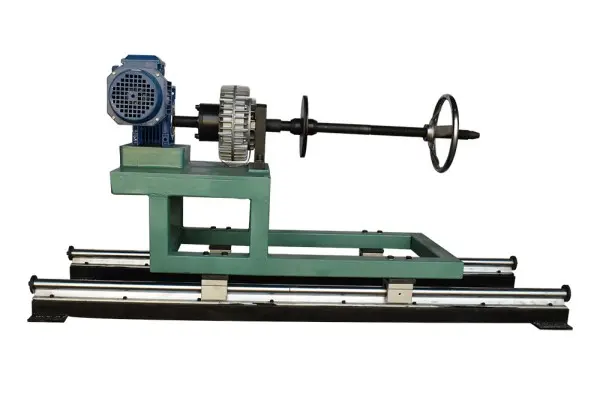

At WUXI SHUHONG MACHINERY TECHNOLOGY CO., LTD., precision and quality are at the forefront of our motor winding solutions. We provide customized winding services tailored to your specific requirements, along with attractive discounts for bulk orders, ensuring unmatched value. Choosing the right factory is crucial, and our expertise guarantees efficient responses to your machinery needs. Our dedicated team focuses on delivering exceptional service, whether you need custom windings or standard models. With state-of-the-art technology and a skilled workforce, we ensure every motor winding meets the highest performance standards. Partner with us and enhance your production capabilities!

How To Compare Winding Of A Motor Winning in 2025 Ahead of the Curve

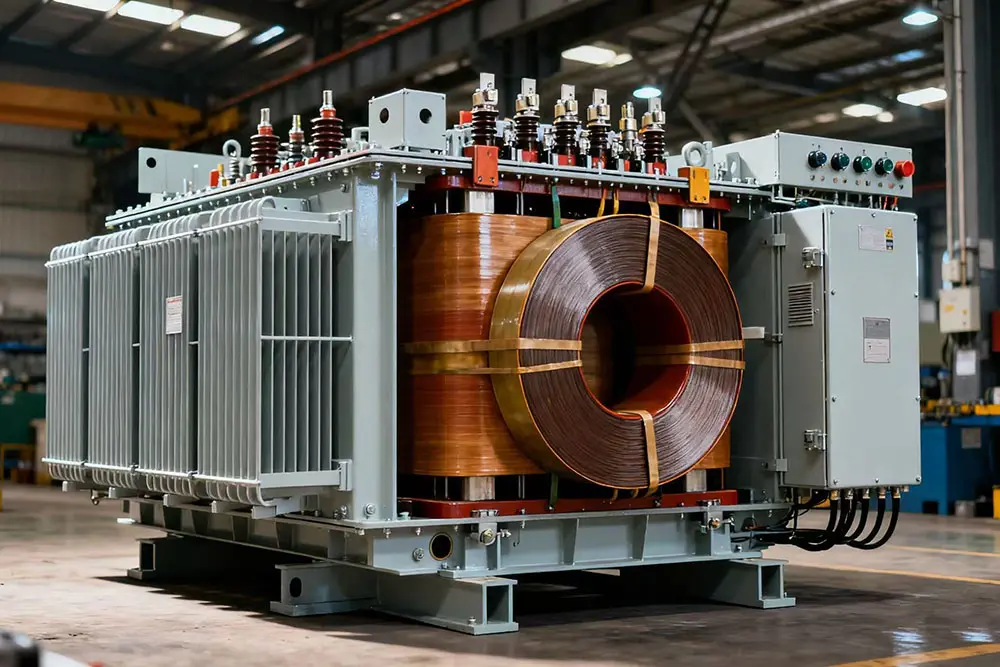

In the rapidly evolving landscape of the machinery industry, understanding how to compare and evaluate motor windings is crucial for global buyers looking to stay ahead of the curve in 2025. With technological advancements and a strong push towards energy efficiency, selecting the right motor winding can significantly impact overall machinery performance and operational costs. Buyers should consider key factors such as material quality, winding design, and the potential for energy savings when making their comparisons.

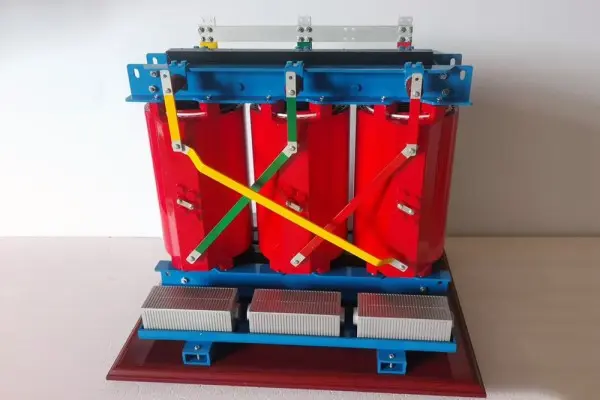

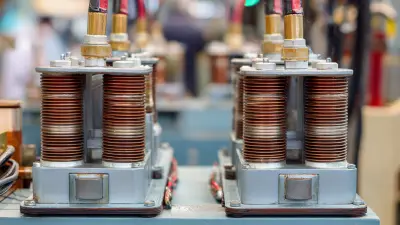

One important aspect of evaluating motor windings is the type of materials used. High-quality copper versus aluminum windings can greatly influence efficiency and conductivity. Additionally, the design of the winding, including the number of turns, layer arrangement, and insulation types, will affect the motor's thermal performance and longevity. Buyers should also assess the manufacturer’s reputation for innovation and adherence to quality standards, ensuring they acquire products that offer reliability and maximum efficiency.

Furthermore, as the industry trends toward sustainability, buyers should factor in the energy consumption and efficiency ratings of motors. Assessing how motor windings contribute to minimizing energy losses aligns with global sustainability goals and can lead to significant cost savings. By prioritizing these elements, procurement professionals can make informed comparisons, paving the way for smarter investments in high-performance machinery that caters to the future demands of energy and technology.

How To Compare Winding Of A Motor Winning in 2025 Ahead of the Curve

| Motor Type | Winding Material | Efficiency (%) | Max Temperature (°C) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| Induction Motor | Copper | 90 | 120 | 25 | 1500 |

| Synchronous Motor | Aluminum | 92 | 130 | 30 | 1800 |

| Stepper Motor | Copper | 85 | 100 | 5 | 400 |

| Brushless DC Motor | Copper | 95 | 140 | 15 | 1200 |

Methods To Winding Of A Motor Your Trusted OEM Partner Guarantees Peak Performance

E

Emma Wilson

High-quality product, no doubt! The support team is truly dedicated and knowledgeable, making my experience smooth and enjoyable.

10

September

2025

E

Ethan Clark

This product is of exceptional quality. The customer service staff were very professional and resolved my concerns efficiently.

24

August

2025

S

Scarlett Scott

Top quality! I truly appreciated the professional and friendly assistance from the after-sales service team.

11

August

2025

V

Victoria Johnson

Incredible product quality! The professionalism and dedication of the after-sales team left a positive impression.

25

September

2025

D

Daniel Martinez

The quality of this product is exemplary. Additionally, the professionalism of the customer service staff made a significant difference in my shopping experience.

05

August

2025

J

James Mitchell

Highly satisfied with my purchase. The product quality is exceptional, and the follow-up support was incredibly professional.

26

August

2025